Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

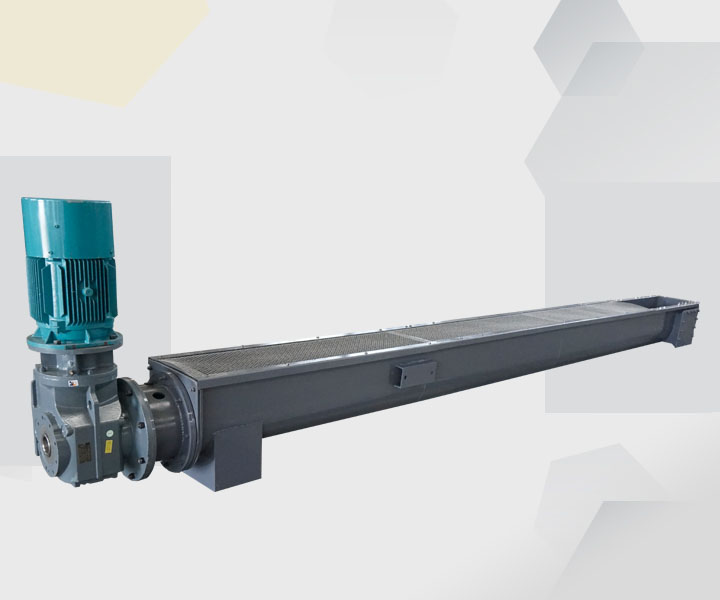

Coal powder, special equipment for coal transportation, material temperature below 50°C, commonly used in coal-fired power plant boiler pulverization system

Price: $560.00-$20,000.00/Set Chat Now

Diameter: 100-1250mm

Delivery capacity: 143 cubic meters per hour

Conveying length: 60 meters

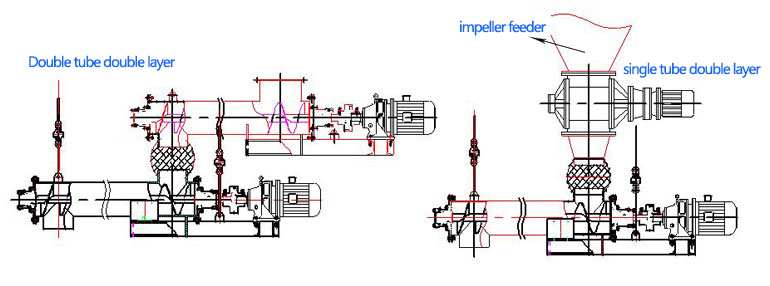

Coal Screw Conveyor is mainly used in the pulverizing system of coal-fired power plant boilers. According to the conveying process requirements of Coal Screw Conveyor, it can be transported by a single unit, or multiple units can be combined with other transport configurations to form a horizontal or inclined conveying system. Coal Screw Conveyor can Utilization within the ambient temperature range of -20°C to +40°C, the temperature of the conveyed material is below 50°C.

The particle size of coal powder is 200 mesh, which is fine powder and has certain fluidity. It is required that the seal of Coal Screw Conveyor should be relatively tight, so as to avoid the influence of material leakage on normal conveying work.

Conveying coal

Conveying pulverized coal

Coal Screw Conveyor can be used for bulk material transportation in coal chemical industry, metallurgy, paper making and construction industry, such as: cement, sludge, coal powder, carbon black, coal slime, slag and other materials.

1. The conveying length of a single machine is up to 60 meters, and it can be used in combination with other equipment to achieve longer distance conveying.

2. It can be arranged horizontally or inclined according to the technical requirements of the site.

3. Good sealing performance, which can reduce leakage caused by poor sealing during pulverized coal transportation.

4. There is a cleaning device at the discharge end, and the position of the inlet and outlet is flexible;

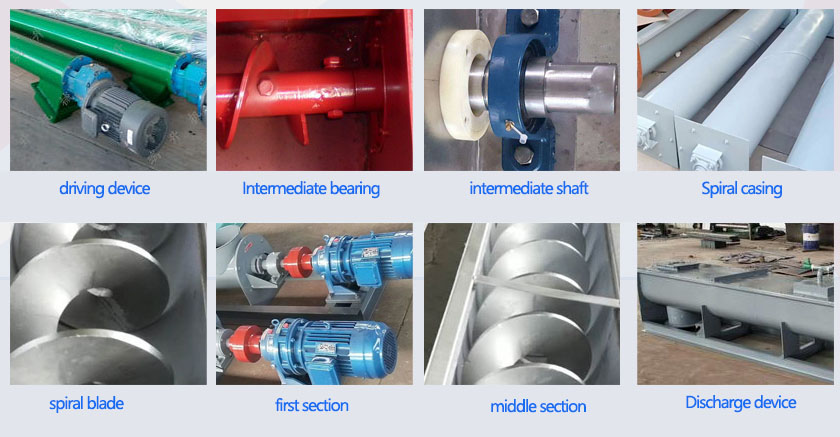

When the Coal Screw Conveyor is started, the Coal feed inlet enters the conveying pipe, driven by the motor, the screw shaft starts to rotate to exert a thrust on the Coal, and under the joint action of the Coal's own gravity and this thrust, the Coal moves forward And discharged through the discharge port to the next process.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Coal Screw Conveyor is composed of driving device, intermediate bearing, screw shaft, screw machine body, screw blade, head section, middle section, tail section, feeding and discharging device and other components.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!