Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

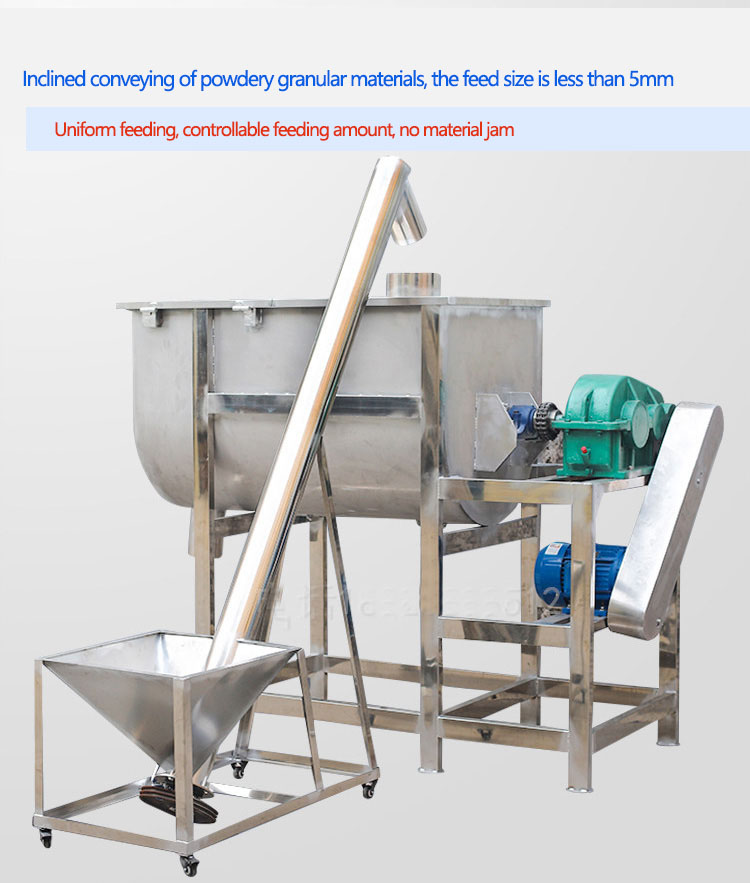

The feeding amount is controllable, the powder/granule material is fed continuously, no material jamming, no arching, smooth discharge, and it has the functions of conveying, sealing, homogenizing and stirring.

Price: $760.00-$20,000.00/Set Chat Now

Hopper capacity: 80-300kg

Feed rate: 468 cubic / hour

Conveying distance: 2-70 meters

Materials: loose materials such as various powdery, granular and small lumps, such as: cement, coal powder, ash, slag, grain

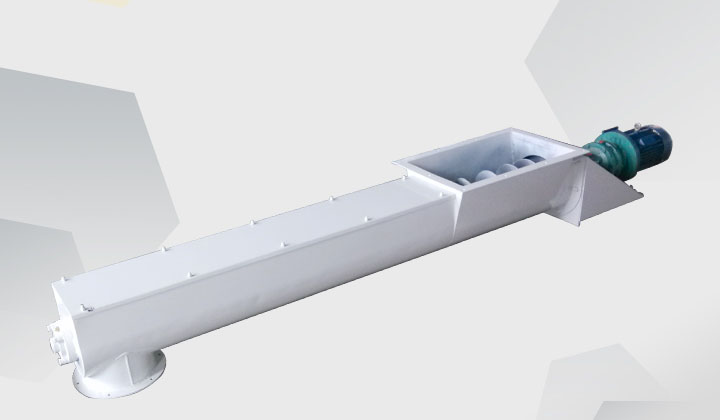

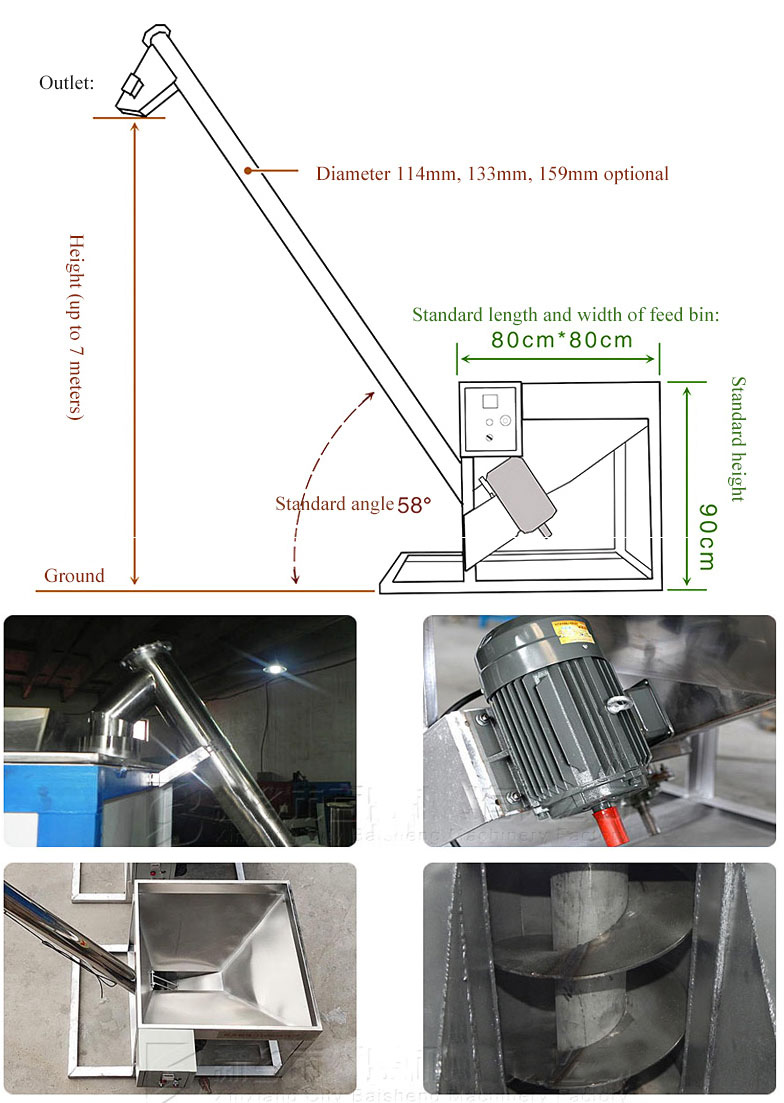

Auger Feeder is mainly used for oblique or vertical conveying of powdery and granular materials. The feeding size is less than 5mm. The silo and conveying pipe are made of stainless steel (materials can be customized according to customer requirements) to ensure that the raw materials are completely pollution-free during the conveying process. The pipeline adopts a closed design, which can effectively prevent dust and effectively isolate materials with high hygiene requirements or strong odors. It has the characteristics of uniform feeding, good sealing, and no dust pollution. (Different diameters, lengths and inclination angles can be customized according to user requirements, and can also be equipped with a speed-regulating motor to achieve the purpose of quantitative feeding.)

material

Stainless steel Auger Feeder: It is mostly used in food, medicine and other industries with high requirements for hygienic environment. It is acid-resistant, corrosion-resistant, wear-resistant, not easy to rust, easy to clean after use, and has a longer life than carbon steel.

Carbon steel Auger Feeder: It is used in industries that do not have very strict sanitation requirements, with low cost, large conveying capacity, good heat insulation effect, no cooling device, and low power consumption.

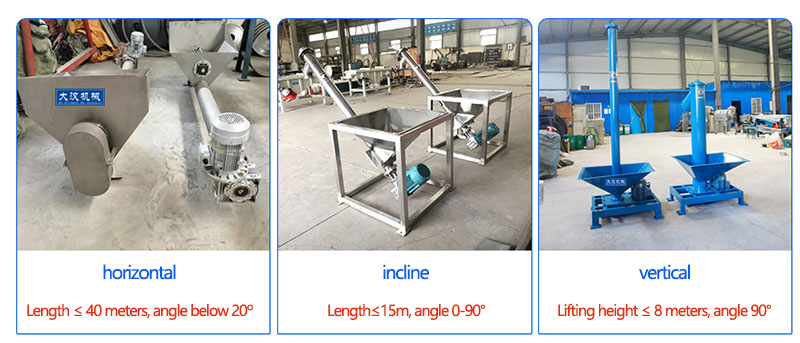

Delivery angle

Horizontal Auger Feeder: It is used for continuous and uniform conveying of loose materials horizontally or slightly inclined (below 20º), and the conveying distance is generally not more than 70 meters.

Inclined Auger Feeder: Used to convey materials within a range of 60°, and the conveying length can reach 60 meters.

Vertical Auger Feeder: Convey materials vertically upward at 90°, the speed is higher than that of ordinary Auger Feeder, and the lifting height does not exceed 8 meters.

small auger feeder conveying cement

conveys wood chips

Auger Feeder can be used for continuous or batch operation, can feed granular, powder, viscous or adhesive type materials, is the choice of users who need to discharge/feed from silos or hoppers, and is widely used in conveying flour processing Materials for industry (bran, flour, etc.), feed industry (pet feed, fish feed) and bridging materials (e.g. sawdust, soybeans, etc.), single-screw and twin-screw models are also available according to the requirements of different industries.

Building materials industry: used to transport granular materials such as cement, sand, lime, etc., widely used in concrete mixing plants, sand and gravel sorting equipment, etc.

Chemical industry: commonly used to transport powdered or granular chemical raw materials, such as fertilizers, plastic particles, pigments, etc.

Food processing industry: used to transport food raw materials, powders, particles and other materials, such as flour, grains, etc.

Mining industry: used to transport ore, coal, slag and other materials to help improve production efficiency and transportation stability.

Waste treatment: used to transport solid waste, sludge and other materials.

The Auger Feeder uses wear-resistant spiral blades to achieve continuous and uniform transportation of powders, granules and other materials, and has the advantages of compact structure and good sealing.

1. The feeding is uniform, and the feeding speed can be controlled by installing a frequency conversion motor, so that the material is not easy to block.

2. The feed motor and vibration motor can be switched independently to control the vibration amplitude. The system has a time relay. Set the time according to the set amount each time to control the feed amount.

3. The direction of conveying materials is reversible, and materials can be conveyed in two directions at the same time. During the conveying process, processes such as mixing, stirring, loosening, heating and cooling can also be completed.

4. The silo and conveying pipe are made of stainless steel (the material can be customized according to customer requirements) to ensure that the raw material is completely pollution-free during the conveying process.

5. The conveying pipeline adopts a closed design, which can effectively prevent dust and effectively isolate materials with high hygiene requirements or strong odors.

When the Auger Feeder is running, the material is transported into the housing of the Auger Feeder through the feed port, the motor in the driving device drives the reducer, and then the coupling transmits it to the screw shaft, the material enters from the feed port, and the internal screw Under the action of centrifugal force and pipe wall friction in the groove, it rotates together with the spiral blade, and slides down the spiral groove under the action of gravity, so that the material is continuously pushed forward and conveyed, and then evenly discharged from the discharge port. next procedure.

| Specifications | Spiral diameter(mm) | Pitch (mm) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | |

| small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

Auger Feeder is composed of AC speed regulating motor, worm gear reducer, feeding chute, feeding screw and base.

Structural features

Using a speed-regulating motor, the feeding amount can be easily adjusted at will;

The spiral feeding is uniform and continuous, which solves the problem of difficulty in adjusting the amount of traditional mechanical materials and uneven addition, reduces the content of residual materials, reduces costs, and improves the process effect;

The area of the material exposed to the air is small, which reduces the oxidation of the material during use and improves the use effect.

According to different process requirements, choose the appropriate model

For small inclination, horizontal and short-distance transportation, horizontal Auger Feeder can be used; for vertical or large inclination transportation with small height, vertical Auger Feeder should be used.

According to the different materials to be conveyed, determine the form of the spiral blade

a. The helical blades of the solid helix are mainly used for conveying dry, low-viscosity small particles or powdery materials, such as lime powder, coal powder, etc.

b. The helical blade of the belt helix is mainly used for conveying lumpy or medium-viscosity materials, such as sludge, etc.

c. Blade-type spiral blades are mainly used to transport tough or compressible materials.

According to the requirements of the process equipment, determine the rotation direction of the spiral blade, the screw shaft and steering, and the combination of the spiral body

The direction of material conveying can be determined by determining the position of the head and tail of the conveyor. The rotation of the spiral blades and the rotation of the shaft must meet the requirements. If the material is discharged in the middle or at both ends, a combination of blades with different rotation directions should be used to weigh a spiral body.

Product customization

Dahan Auger Feeder can be processed and designed according to conveying materials, conveying length, import and export distance, conveying volume, installation inclination angle, etc.

Dahan Screw Feeder is committed to providing customers with high-quality and reliable feeding equipment. We use wear-resistant and corrosion-resistant high-quality materials to manufacture key components of screw feeders, such as spiral screws, conveying troughs, etc., to ensure that the equipment has good durability and stability in long-term use. We provide a variety of models and configurations of screw feeders to meet the needs of different customers. Whether it is conveying powdery materials, granular materials or block materials, we can provide suitable equipment to ensure the best feeding effect.

Xinxiang Dahan Machinery Co., Ltd. is committed to providing customers with high-quality screw feeder products and professional solutions. Please feel free to contact us for more information about product details and customized services.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!