Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

It can transport powdery, granular and small block materials at an angle of ≤90°, the motor power is 7.5KW-11KW, the speed is fast, the material flow is stable, and it is not easy to accumulate materials.

Price:$500.00 - $20,000.00/Set Chat Now

Delivery capacity: 142 cubic / hour

Conveying length: 1-70 meters

Tilt angle: 0°-90°

User protection: 30-day price guarantee, 30-day quality problem refund, 365-day free maintenance

Test machine with materials: free test machine with materials, special reception

Fast delivery: regular models will be shipped on the same day, and customized models will be shipped within 7 days

Worry-free after-sales: regular return visits, after-sales tracking, 7*24h customer service online

Inclined Screw Conveyor is used to obliquely transport bulk materials such as powder and granules from one layer to another. The inclination angle generally does not exceed 90°. It can be directly connected and fixed with the supporting equipment. It does not need foundation and makes full use of space. In addition, the inclined screw conveyor can be equipped with universal wheels at the bottom according to the user's site requirements, and can be moved freely.

inclined screw conveyor for powder feeding

Inclined screw conveyor for conveying cement powder

Inclined screw conveyor is suitable for conveying powdery, granular and small lump materials, such as cement, coal powder, grain, fertilizer, ash, sand, coke and other materials with a temperature lower than 200°C.

Inclined screw conveyors are widely used in various industries, including but not limited to the following areas:

Agricultural field: Used for conveying grain, feed, fertilizer and other granular materials to improve production efficiency.

Construction field: often used in concrete mixing stations to transport cement, sand and other raw materials to simplify the construction process.

Chemical industry: suitable for transporting chemical raw materials, powders, granules and other materials to ensure smooth production process.

Food processing field: used to transport flour, powdered sugar, cereals and other food raw materials to ensure the continuity of the food processing production line.

Mining field: Commonly used in the transportation of granular materials such as ore and coal to improve the efficiency of ore mining and processing.

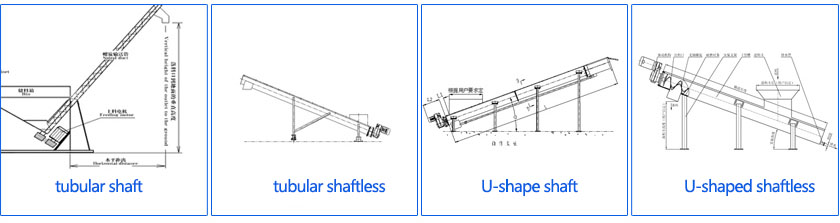

Inclined Screw Conveyor with shaft tube: about 45°, and U-shaped Inclined Screw Conveyor with shaft: about 20°-30°.

Shaftless tubular Inclined Screw Conveyor inclination angle: about 30°, shaftless U-shaped Inclined Screw Conveyor inclination angle: about 20°-30°.

Reminder: For materials with poor fluidity, the inclination angle can reach 50°. However, if the material is conveyed in this way, a certain pressure must be applied to the feed inlet, and the material is squeezed into the conveying body. Moreover, the bearing at the bottom of the equipment needs to bear Huge pressure, the bearing is easily damaged.

1. It is suitable for inclined conveying materials within the range of 90°, and occupies a small area.

2. The conveying capacity can reach 142 cubic meters per hour, and the long-distance conveying of 4-70 meters can be realized.

3. The speed is fast and the conveying is uniform, which can ensure that the material will not be blocked during the conveying process.

4. Good sealing performance, basically no dust pollution, material spillage, etc. during the entire conveying process, which improves the operating environment.

5. The material flow can be controlled through the loading and unloading gate.

The Inclined Screw Conveyor uses the rotating helical blade to push the material to be transported by the screw conveyor. The force that prevents the material from rotating with the screw conveyor blade is the material's own weight and the frictional resistance of the screw conveyor casing to the material.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Inclined screw conveyors are made up of multiple components that work together to achieve the material conveying function. The following are the main components of inclined screw conveyors:

1. Screw shaft: The screw shaft of Dahan inclined screw conveyors is usually made of steel, which has sufficient strength and wear resistance and is responsible for pushing the material along the screw shaft.

2. Spiral blades: The shape of the blades has shaftless and shafted designs, and the spacing of the blades will also affect the efficiency and speed of conveying materials.

3. Spiral pipe: The shape is round and made of carbon steel with stainless steel. The circular pipe can effectively prevent the material from scattering.

4. Motor and transmission device: Different forms of transmission devices such as electric motors, hydraulic motors or pneumatic devices can be used according to customer needs.

5. Feed port and discharge port: The feed port is used to load materials into the conveyor, and the discharge port is used to unload materials. In addition, the design of the inlet and outlet ports will also affect the efficiency and smoothness of the material in and out.

Stainless steel material-stainless steel material can also be divided into 304, 310, 310L, 316, and 316L models (all models can be made of stainless steel, but when the conveying distance is long, the surface area increases and the grinding difficulty increases. If you choose sandblasting, it will not be as bright as common stainless steel visually, but the quality will not be affected)

Carbon steel material-Carbon steel material is a commonly used material for Inclined Screw Conveyor. This material has low cost and can also realize the normal transportation of materials.

| pipe diameter | Motor Power | Motor speed | model | material |

| 100mm | 1.5 kilowatt motor | 1450/min Level 4 | vertical/slanted (optional) | Stainless Steel/Carbon Steel (Optional) |

| 140mm | 2.2 kilowatt motor | |||

| 165mm | 2.2 kilowatt motor | |||

| 220mm | 3 kilowatt motor | |||

| 275mm | 4 kilowatt motor |

The speed of the Inclined Screw Conveyor is generally 1450r/min. The speed of the inclined screw conveyor can be adjusted by itself. The larger the angle, the greater the required speed.

Note: The speed of the Inclined Screw Conveyor cannot be unlimited. When the speed reaches a certain limit, the material will be thrown outward due to excessive centrifugal force, resulting in the failure of the conveying process. The larger the angle of Inclined Screw Conveyor, the same speed ratio and type of conveyor, the conveying capacity will be weakened.

Inclined screw conveyors are widely used in various industries when the inclination angle is 45%. The following are some product solution proofs:

1. Food processing industry: used to transport raw materials from the ground to the material handling equipment above to ensure the continuity and efficiency of the production line.

2. Chemical industry: often used to transport powdered and granular chemical raw materials, which can accurately and stably transport chemical raw materials to ensure the safety and stability of the production process.

3. Building materials industry: used to transport raw materials such as sand and cement between different heights, which can achieve efficient transportation of building materials, reduce labor costs and improve production efficiency.

4. Agricultural field: can be used to transport materials such as grains and feeds, which can help farmers improve production efficiency, reduce labor labor, and ensure the safety of grain and feed transportation.

1. Material characteristics: material name, material particle size, whether the material has hardness, whether the material has viscosity, material temperature, etc.

2. Determine the tilt angle

3. Determine the material

4. Determine the size: such as pipe diameter, length, length of the outlet, distance from the outlet to the ground, height of the bracket, width of the hopper, etc.

Our inclined screw conveyors are mainly made of high-strength steel to ensure that the equipment has sufficient strength and durability and can operate stably in various working environments.

or the conveying needs of different materials, we can also provide customized options for wear-resistant coatings to extend the service life of the equipment and reduce maintenance costs.

or humid and corrosive environments, we can choose appropriate anti-corrosion treatment according to customer needs to ensure long-term and stable operation of the equipment.

Design perspective:

We provide flexible customized services and customize inclined screw conveyors of different specifications and materials according to customers' specific needs and working environments to meet customers' requirements to the greatest extent.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!