Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Vertical conveyor conveying powdery, granular and non-viscous dry material at vertical large or inclination angle.

more than 10 models for selection

conveying capacity up to 134.2 t/h

Power:1.1-5.5KW

Material:Carbon Steel/ Stainless Steel 304

Application: Vertical conveyors are widely used in many industries, including but not limited to conveying grain, feed, cement, sand, lime, fertilizer, flour, cement, etc.

Vertical Conveyor is a kind of highly efficient environmental dedusting equipment with wide application range, long service life and low production cost, and can meet the requirements of different environmental protection users with high quality and high performance. Material temperature generally cannot exceed 100 C. Vertical screw conveyor is not suitable for conveying bulk and viscous materials, nor for conveying materials with very small bulk density (less than 0.5t/m3) and strong fluidity, such as fly ash.Used in building materials, metallurgy, chemical industry, mining, machinery manufacturing, coal ash, tobacco, food, medicine and other industries.

Vertical conveyors can be divided into many types according to their design and working principle. The following are some common types of vertical conveyors:

Continuous elevator: It is a conveying equipment that runs continuously in the vertical direction, usually driven by a chain, belt or screw mechanism to continuously convey materials or products.

Bucket elevator: Bucket elevator uses a bucket or container to lift materials vertically from the bottom to the top along the operation of a chain or belt. It is suitable for conveying granular or powdery materials.

Screw conveyor: It uses spiral blades to rotate in a spiral pipe to convey materials vertically along the spiral axis. It is suitable for conveying powdery or granular materials.

What are some unique uses of vertical conveyors?Vertical conveyors can be applied to many unique scenarios and uses due to their special design and functions. Here are some unique uses of vertical conveyors:

Building structure construction: It can be used to transport materials such as concrete and mortar.

Food processing: It can be used to vertically transport food between different temperature zones to achieve temperature control and separation of processing processes.

In pharmaceutical manufacturing: Vertical conveyors can be used to transport pharmaceutical raw materials or finished products in a clean environment to ensure product quality and hygiene standards.

Vertical agriculture: It can be used to transport soil, water and plant nutrients to help realize the automation and efficient operation of vertical agricultural planting systems.

Mining industry: It can be used to quickly and safely lift ore or miners in deep wells.

1.The large bearing capacity, safe and reliable.

2.Strong adaptability, easy installation and maintenance, long service life.

3.The machine is small in size, high speed, ensure rapid delivery uniformity.

4.The discharge end is equipped with cleaning device, low noise, strong adaptability, in and out of the mouth position arranged flexibly.

5.Good sealing, shell made of seamless steel tube end use flange connection each other as a body, good rigidity.

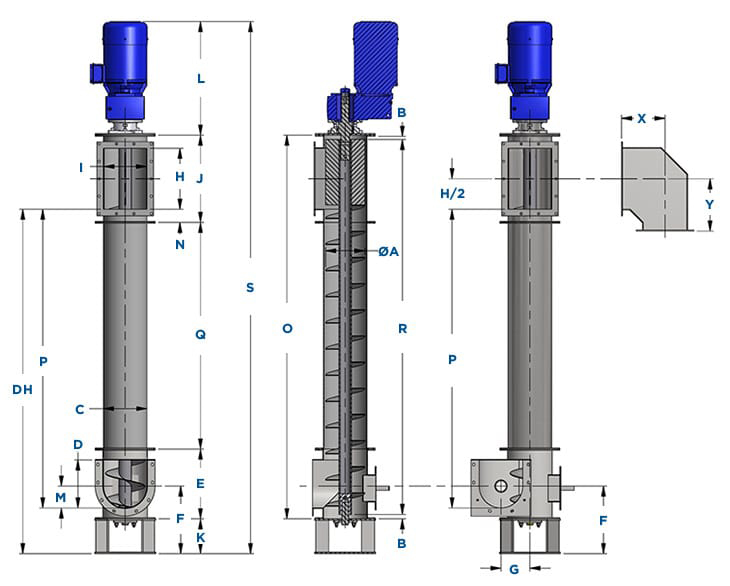

The horizontal groove body (i.e. the feeding spiral groove body) consists of two parts of the vertical body. Vertical body is divided into three parts: head section, middle section and tail section. Each part has different lengths according to machine height. It can form a whole machine with different heights of 3-15m. Each 0.5m increase of screw machine is a height specification for users to choose.

A vertical conveyor is a device used to transport materials in a vertical direction. Its working principle is basically to use a conveying carrier (such as a chain, belt, bucket or spiral blade) to transport materials from the bottom to the top or vice versa. The following is the basic working principle of a vertical conveyor:

Material feeding: The material is put into the feed end (bottom) of the conveyor, which can be through a conveying bucket, conveyor belt, etc. The material is carried upward as the conveying carrier moves.

Vertical conveying: The conveying carrier runs upward along the structure of the conveyor, gradually lifting the material to a set height. This process can be continuous or intermittent, depending on the design and working mode of the conveyor.

Unloading: When the material reaches the top, it can be unloaded to the target location, such as another conveying equipment, container or processing equipment, by a suitable device.

| Fertilizer | Coal |

| Gravel | Sand |

| Grain | Lump coal |

When choosing a screw conveyor, it is crucial to consider the material and structure. Here are some key points to note when considering these two aspects:

Material:

Conveying material characteristics: Choose the right material according to the nature of the material to be conveyed. For example, for materials that are prone to wear, choose a material with strong wear resistance; for materials that are prone to corrosion, choose a material with good corrosion resistance.

Stainless steel: For applications that need to meet hygiene standards or have corrosion resistance requirements, stainless steel is a common choice, such as 304 or 316 stainless steel.

Carbon steel: Carbon steel is usually an economical and practical choice, but additional protection may be required in humid or corrosive environments.

Coating: Special coatings such as polyurethane, polyurethane, etc. can be added to the surface of the screw conveyor as needed to improve wear resistance or corrosion resistance.

Structure:

Spiral structure: The spiral structure of the screw conveyor can be selected in different forms according to needs, such as a solid solid spiral or a hollow spiral, which is suitable for different conveying requirements.

Support structure: Make sure the conveyor has sufficient support structure to withstand the weight and pressure during the conveying process while maintaining stability.

Drive system: Choose a reliable drive system, such as chain drive or belt drive, to ensure efficient operation of the conveyor.

Guide device: Add appropriate guide devices to the screw conveyor to ensure that the material moves along the correct path during transportation to avoid deviation or blockage.

Dust-proof design: Consider the dust-proof design of the screw conveyor to reduce dust generation and ensure a clean operating environment.

The price of a screw conveyor will vary according to many factors, including model, size, material, production process, brand, market demand, etc. Generally speaking, the price of a screw conveyor ranges from $500.00 to $5,000.00/Set, and for special requirements or custom-designed equipment, the price may be higher.

Dahan Vertical Screw Conveyor strictly selects high-quality materials such as 304 stainless steel, carbon steel, etc. during the manufacturing process to ensure the durability and stability of the product. For special needs, we also provide special coating options such as wear-resistant and corrosion-resistant, and provide a full range of pre-sales consultation and after-sales services. Whether it is product selection, installation and commissioning or after-sales maintenance, we have a professional team to provide support and solutions for customers. Whether it is a small customized project or a large industrial application, Dahan Vertical Screw Conveyor will provide you with the best conveying solution with a professional and efficient attitude. Looking forward to working with you!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!