Tel:0086-0373-5433765 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

No central shaft design to prevent material clogging and entanglement, the conveying capacity is 1.5 times that of the shaft screw conveyor, special equipment for kitchen waste, domestic waste, and sludge.

Price:$650.00-$3,560.00/Set Chat Now

Delivery capacity: 458 m³/h

Length: 40~70 meters

Speed: 13~140 rpm

Torque: 4000N/m

Materials: sludge, cement, domestic waste, kitchen waste, concrete, clay

Shaftless Screw Conveyor is designed without a central shaft, which can transport materials that are difficult to convey by ordinary screw conveyors, such as wet, pasty materials, semi-fluid, viscous materials, easy to entangle and easy to block, and the conveying capacity can reach 458 cubic meters. It is a shaft screw 1.5 times that of the conveyor, it is a special equipment for kitchen waste, domestic garbage, and sludge. The shaftless screw conveyor is generally arranged horizontally, and can also be placed at an angle (the angle of inclination does not exceed 45°), and the conveying length of a single machine can reach 60 meters.

Conveying Sediment

Conveying Silt

Conveying Sludge

conveying Concrete

Shaftless screw conveyor can convey wet and pasty materials, semi-fluid and viscous materials, easily entangled and easily clogged materials, materials with special hygienic requirements, such as: sludge, cement, mud, domestic garbage, kitchen waste, concrete , clay, etc.

Chemical industry: used to transport chemical raw materials such as powders, granules, and pellets, such as fertilizers, plastic granules, pigments, etc.

Food processing industry: suitable for transporting food raw materials, powders, granules, and pellets, such as flour, powdered sugar, and grains.

Building materials industry: used to transport building materials such as cement, sand, gravel, and sludge, and is widely used in concrete mixing stations, sand and gravel yards, and other fields.

Metallurgical industry: used to transport ore, slag, molten metal, such as iron ore, aluminum slag, etc.

Agricultural field: suitable for transporting agricultural raw materials such as feed, grains, and fertilizers, such as feed processing plants, agricultural product processing plants, etc.

Sewage treatment plant

The dehydrated sludge cake is transported to the sludge transport vehicle through the sludge Shaftless Screw Conveyor, and transported to the sludge landfill for landfill treatment

Delivery capacity: 20 tons/hour

Conveying length: 3 meters

Recommended: WLS160

Advantage: ①The sludge has many impurities and strong viscosity. The shaftless design can effectively prevent material clogging; ②The material is polluting, and the fully enclosed conveying method can reduce material leakage.

point: When the moisture content of the material is greater than 80%, the conveying inclination should be ≤25°

Garbage disposal station

It is used for the treatment and transmission of kitchen waste or domestic waste generated in household kitchens, restaurants, restaurants, canteens, markets and other industries

Delivery capacity: 26 tons/hour

Conveying length: 4 meters

Recommended: WLS315

Advantage: ① There are many impurities in the garbage, which can eliminate the blockage caused by winding during the transportation process. ②It is easy to produce leachate, and the smell will overflow. The fully enclosed and easy-to-clean spiral surface can prevent pollution.

point: Garbage is perishable and must be made of stainless steel

concrete mixing plant

Cement or dry powder is directly fed into the mixing host through the pan feeder and screw conveyor on the metering bin

Delivery capacity: 30 tons/hour

Conveying length: 12 meters

Recommended: WLS400

Advantage: ①The equipment can complete conveying, mixing, stirring, loosening and other processes, which can prevent blockage caused by agglomeration. ②The conveying length of a single machine is up to 60 meters, which can be arranged horizontally or inclined according to the site.

point: Powder materials such as cement are conveyed in a sealed manner to avoid environmental pollution and damp materials

industrial waste

Slag, fly ash, incineration fly ash and other materials are stirred and conveyed in the conveying tank according to the proportion until they are sent to the next process

Delivery capacity: 1 ton/hour

Conveying length: 4 meters (angle 20°)

Recommended: WLS200

Advantage:It adopts a fully enclosed structure, which can reduce dust pollution during the conveying process, and can be used in conjunction with other conveying devices to complete collection, distribution, mixing, mixing, dehydration, batching, stacking, etc.

point: There are horizontal, inclined and combined forms, and can be used in conjunction with other devices

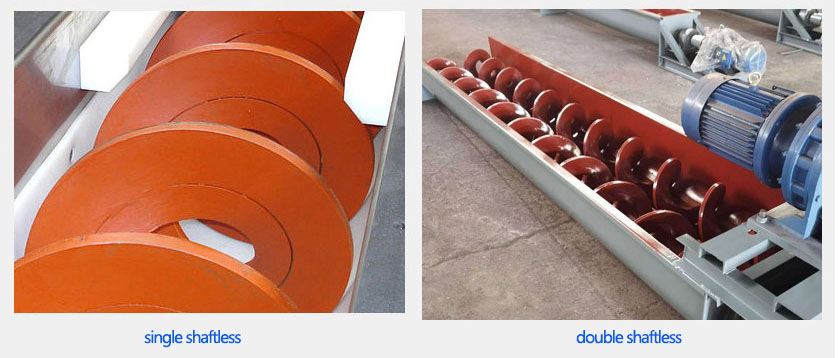

Single Shaftless Screw Conveyor—Consists of 1 screw, without mixing function.

Double Shaftless Screw Conveyor—composed of two spirals, the spiral blades rotate in opposite directions, and the conveying capacity is 1.5-2 times that of a single spiral, and can simultaneously perform functions such as conveying, mixing, and stirring.

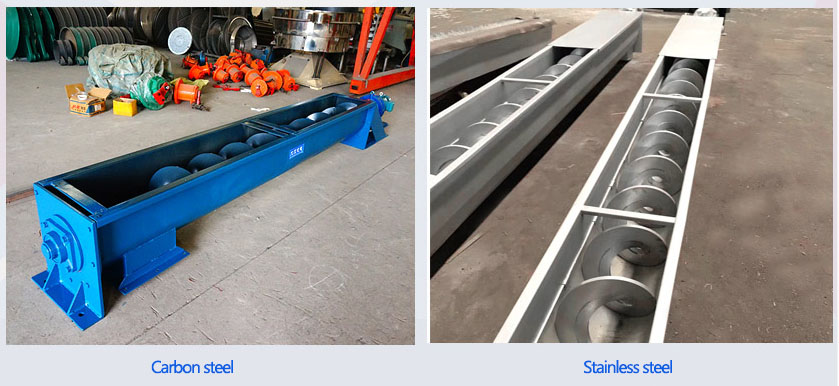

Carbon steel Shaftless Screw Conveyor—Made of carbon steel, suitable for conveying common materials, mainly used in cement, coal, stone and other industries with high wear and no special requirements.

Stainless steel Shaftless Screw Conveyor—304/316 stainless steel material, corrosion resistance, high temperature resistance, not easy to rust, special for food and pharmaceutical industries. Mainly used in grain, chemical, food and other industries that have requirements on the conveying environment. High cleanliness, no contamination of materials.

Tubular Shaftless Screw Conveyor: Made of seamless steel pipe, good sealing

U-shaped Shaftless Screw Conveyor: Small range/small distance conveying, dust cover is removable

Strong anti-winding: no central shaft design, can convey belt-shaped, viscous materials, easy-to-wind materials, and avoid material clogging.

Large conveying capacity: the torque of the shaftless screw conveyor can reach 4000N/m, and the conveying capacity is 1.5 times that of the shafted one, reaching 458 cubic meters per hour.

Flexible layout: the conveying length of a single machine can reach 60 meters, and multi-stage series installation can be adopted according to user needs.

Sealed conveying: The tank cover with gasket can avoid material leakage, no peculiar smell leakage, and ensure the sanitation of the conveying environment.

The Shaftless screw conveyor is driven by the motor to run the cycloidal reducer, and the screw is rotated by the transmission of the mechanical seal shaft and the connecting plate on the shaftless screw body. When the material enters the feeding port, it is driven forward by the screw blade. Move until the outlet discharges.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

Different shapes

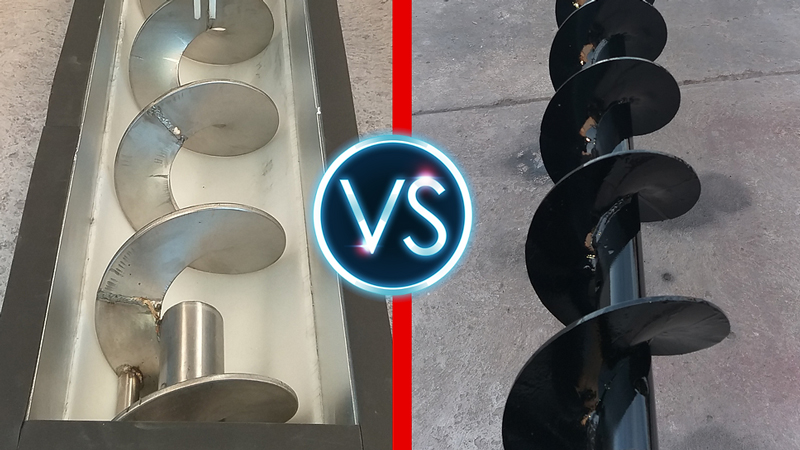

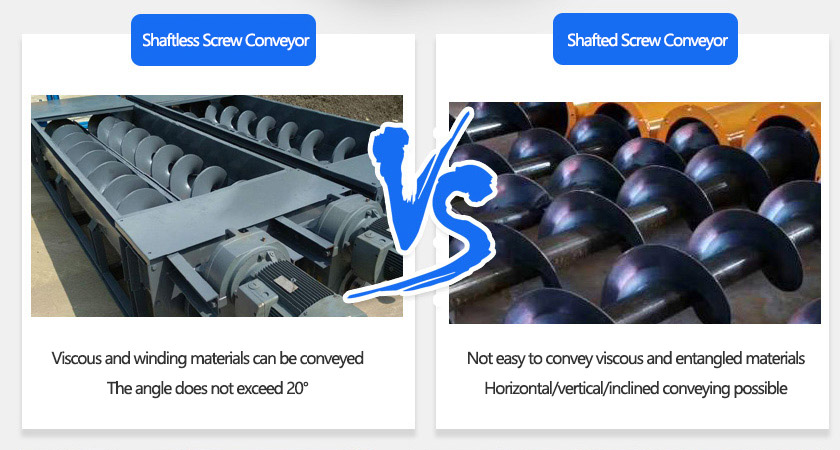

The difference is mainly in the blades. The shaftless screw conveyor blades are designed without a central shaft, which is anti-winding.

Conveying different materials

Shaftless screw conveyor is suitable for conveying wet and pasty materials such as sludge, garbage, lime, semi-fluid and viscous materials, materials that are easy to entangle and block or have special hygienic requirements.

Shafted screw conveyor materials are suitable for powder materials, small particle materials, etc. If viscous materials are conveyed, the materials will stick to the blades and cause material blocking.

Different delivery angles

The Shaftless screw conveyor is generally conveyed horizontally, and the maximum inclination angle generally does not exceed 20° (according to actual usage conditions). Shafted screw conveyors can be arranged horizontally, inclined or vertically.

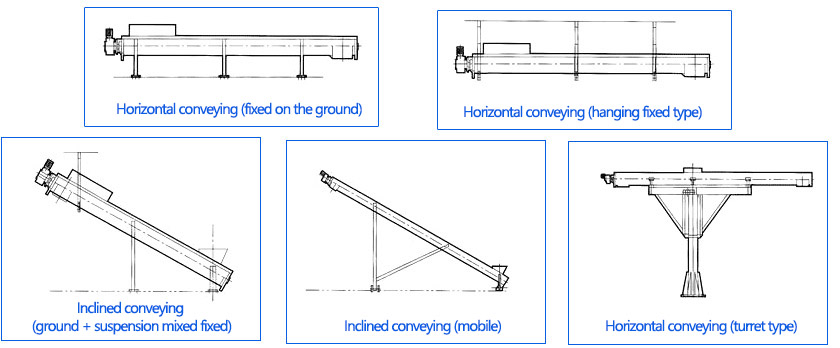

Installation method: The company can provide hanging type according to needs; ground and hanging mixed type; mobile type, rotary type and turret type that can rotate around the axis of the feed inlet.

Xinxiang Dahan Machinery Co., Ltd. is a manufacturer specializing in the production of shaftless screw conveyors. The company uses high-quality wear-resistant materials such as stainless steel and carbon steel to ensure that the equipment has stable performance and durability in long-term use. The spiral screw and the conveying pipe wall of the conveyor are made of special materials, which can adapt to the conveying requirements of different materials. We provide a variety of models and specifications of shaftless screw conveyors to meet the needs of different customers. Whether it is conveying powdery materials, granular materials or block materials, we can provide suitable models and configurations to ensure the best conveying effect. Xinxiang Dahan Machinery Co., Ltd. is committed to providing customers with high-quality shaftless screw conveyor products and thoughtful after-sales service. Customers are welcome to contact us at any time to obtain more detailed information about product models, materials and customized services.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!