Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

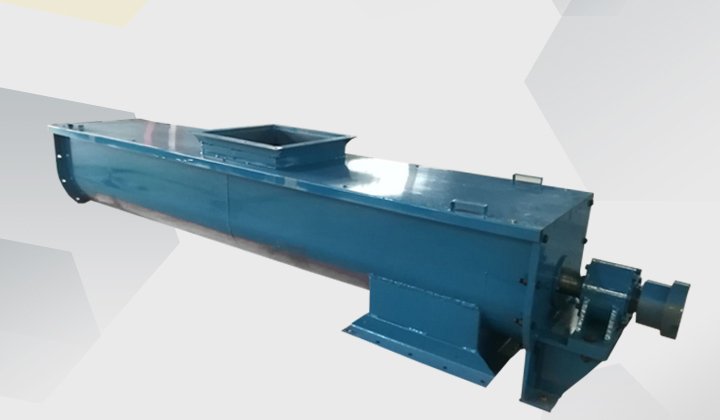

Auger Conveyor is used for horizontal, inclined and vertical conveying of various powders, granules and small block materials. During the conveying process, it can complete the functions of mixing, stirring and cooling of materials, with large torque, fast speed and no material blocking.

Price: $500.00 - $20,000.00/Set Chat Now

Diameter: 100mm-1250mm

Length: 2-70 meters

Capacity: 458m³/h

Material: carbon steel, stainless steel

Materials: flour, soybeans, rice, sawdust, sludge, cement, concrete, garbage, plant ash, gravel, copper ore powder, concrete, fertilizer, etc.

Auger Conveyor is mainly used for conveying powder, granules and small block materials, and can convey materials horizontally, inclined or vertically. It is divided into shaft screw conveyor, shaftless screw conveyor, tubular screw conveyor, U-shaped screw conveyor, Stainless steel screw conveyors, etc., have a full range of equipment models, and the conveying capacity can reach 458 cubic meters per hour. They are commonly used in chemical, building materials, grain, food and other industries.

Auger Conveyor can be used in food, building materials, metallurgy, coal, chemical, electric power and other industries to convey powder, granular or small lump materials, such as cement, concrete, mud, feed, chemical fertilizer, fly ash, coal, sawdust, starch , corn, wheat and other materials, it is not suitable to transport materials that are perishable, viscous, bulky and easy to agglomerate.

Screw conveyors are widely used in mixing stations, sewage treatment plants, fertilizer feeding and cement plants, as follows:

Mixed station powder conveying system: It can convey raw materials such as cement, sand, powder additives from storage bins to concrete mixers to achieve accurate measurement and continuous feeding of raw materials.

Sewage treatment plant sludge treatment: It conveys sludge from sedimentation tanks, sedimentation tanks, etc. to sludge dewatering equipment or drying equipment to achieve sludge treatment and disposal.

Fertilizer feeding: It is used for conveying and adding fertilizer raw materials. It can convey granular or powdered fertilizer raw materials from storage bins to equipment such as mixers, granulators or packaging machines.

Cement plant cement material conveying system: It is used for material conveying in cement clinker, cement grinding and cement packaging. It can convey cement raw materials from storage equipment to production lines such as crushing equipment, coal mills, clinker mills, etc. to achieve material conveying and processing in the cement production process.

| Classification | Tubular Auger Conveyor | U-shaped Auger Conveyor | Shafted Auger Conveyor | Shaftless Auger Conveyor | Stainless Steel Auger Conveyor |

| Features | 70 meters long conveyor | Small-scale/short-distance conveying, multi-point feeding | There are single axis and double axis | No central shaft, strong anti-winding performance, the conveying capacity is 1.5 times that of the shaft | Resistant to 200° high temperature, acid and alkali corrosion resistance, not easy to rust, clean and hygienic |

| Conveying capacity | 142 cubic / hour | 134 cubic / hour | 142 cubic / hour | 458 cubic / hour | 9-134.2 cubic / hour |

| Materials | Powder/granule/small block material | Pasty, viscous, ribbon-like, easily entangled materials | Food/medicine and other industries with hygienic requirements | ||

1. Auger Conveyor is small in size, stable in operation and large in carrying capacity, with a conveying capacity of 1.4-458 cubic meters per hour and a conveying length of up to 70 meters;

2. Remarkable conveying effect: the high speed of the whole machine can ensure the rapid and uniform conveying of materials;

3. Good sealing, the shell is made of seamless steel pipe, and the ends are connected with each other by flanges, with good rigidity, which can be fully enclosed to prevent dust pollution, and can also be opened for transportation;

4. Reasonable design and long service life: the location of the inlet and outlet is flexible, and the discharge end is also equipped with a cleaning device, so the conveyor has a long service life;

5. During the conveying process, it can also complete the process of material mixing, stirring, cooling and so on.

When the material enters the casing of the Auger Conveyor, it does not rotate with the spiral body due to the gravity of the material and the frictional force on the casing. The material moves forward under the push of the rotating helical blade until it is discharged from the discharge port.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

An Auger Conveyor usually consists of three parts: the screw machine body, the entry and exit device, and the drive device.

Drive device: It consists of a motor and a reducer.

Spiral blade: It can be divided into several forms such as full blade type, blade type, paddle type, and tooth type.

Chassis: There are two types of "U"-shaped casing and "O" casing.

Screw shaft: hollow, made of steel pipe, high strength, light weight, easy to connect. Use a short length of solid shaft at the shaft-to-shaft connection and where you mount the bearings. Extend the solid shaft into the hollow shaft at the joint and use high-strength bolts to pass through the hollow shaft and the solid shaft in a mutually perpendicular direction to fix and connect the helical shaft.

1. Conveying materials

It mainly includes the wrong viscosity of the material, the water content, the acidity and alkalinity, and whether it can be broken. Different material properties require different Auger Conveyor models to be selected. In terms of different spiral blade forms, full-surface blades should be used when conveying materials with good scattering properties such as wheat and rice; belt-type blades should be used when conveying oily materials with high viscosity and easy bonding to prevent clogging . At the same time, if the raw grain is to be transported and does not need to be broken, Auger Conveyor is generally not used. In terms of design with or without a central shaft, environmental-friendly enterprises are involved in the transportation and measurement of foggy sewage, sludge, and domestic waste. Such materials are viscous and entangled to a certain extent, so they need to adopt a design without a central shaft to prevent materials from sticking to the surface. on the spiral blade.

2. Delivery capacity

Common screw diameters are 100mm, 200mm, 250mm, 315mm, 400mm, 500mm, 600mm, etc. The larger the diameter, the greater the conveying capacity, which can be selected or customized according to the specific conveying capacity.

The conveying speed of the Auger Conveyor should not be too high, otherwise it will have a greater impact on the screw blades, resulting in increased wear on the blades and U-shaped grooves, affecting the service life and metering efficiency of the feeder.

4. Use the on-site environment

The use site of Auger Conveyor determines the length, inclination angle and model of the equipment. For different lengths and inclination angles, the required power, blade thickness and pipe wall thickness of the screw feeder will be different.

Dahan Screw Conveyor We provide a variety of models of screw conveyors, suitable for horizontal and oblique conveying, mainly including U-shaped screw conveyors, shaftless screw conveyors, hose screw conveyors, etc. Different hose materials and diameters can be customized according to customer needs to meet the needs of different industries and applications. We use high-quality materials such as carbon steel and stainless steel to manufacture conveyors to ensure that the products are wear-resistant and corrosion-resistant, and increase their service life. We provide customers with customized products and professional after-sales service. No matter what industry you are in, we can provide you with efficient and reliable screw conveyor products.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!