Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

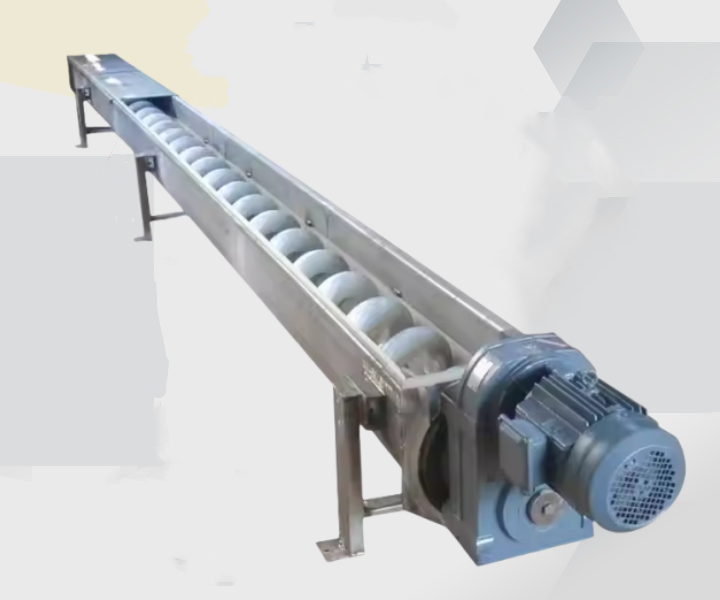

Screw conveyors are mainly used to process powder and granular materials and can be used in horizontal or inclined industrial and mining environments.

Conveying capacity: 0.5-40m³/h

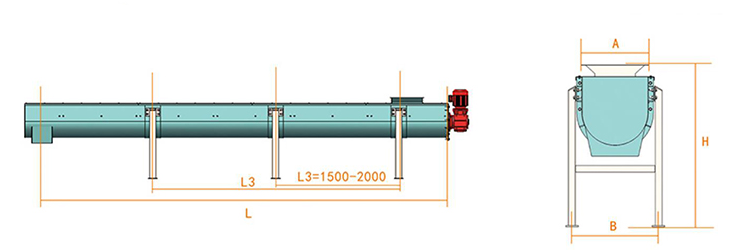

Length: 30 meters

Speed: 71-50r/min

Conveying capacity: 0.5-70m³/h

Applicable materials: can transport powdered, granular or block materials from one location to another

Application areas: can be used for food processing (flour, powdered sugar, puffed food, biscuits, feed, etc.), chemical industry (alumina, potassium chloride, phosphate, etc.), mining industry (ore, coal, slag), building materials industry (cement, lime, stone), waste treatment (sludge, garbage, etc.)

Product customization: material (carbon steel or stainless steel), feed pipe diameter, inlet and outlet distance, feed port size, feed port distance from the ground, angle, etc. (customized on demand)

Screw Conveyor is a commonly used continuous conveying equipment, usually composed of three materials: carbon steel, stainless steel and plastic. It uses spiral blades to move materials. It can be used to transport powdered, granular and block materials. Due to its simple structure, reliable and stable, it has become an important equipment in the production process.

Screw conveyor, also known as screw conveying equipment, is a commonly used continuous conveying equipment. It is usually made of three different materials: carbon steel, stainless steel and plastic, and is used in different scenarios. It uses spiral blades to move materials and transport powdered, granular and block materials to designated locations. And it can change its conveying angle according to its own conveying scenario. It is an important equipment in many industries.

Screw conveyor is a common conveying equipment, and its functions mainly include the following aspects:

Conveying materials: The main function is to convey materials from one place to another, which can be conveyed horizontally, inclined or vertically.

Mixing and stirring: During the conveying process, the rotation of the spiral blade mixes and stirs the materials, so that the materials can be mixed during the conveying process.

Controlling material flow: During conveying, we can control the discharge speed of the material by adjusting the spiral blade pitch speed.

Strong plasticity: Different models can be selected according to different working environments and material characteristics to complete the material processing.

Cooling treatment: We have cooling screw conveyors that can handle some high-temperature materials. The products produced can be cooled by screw conveyors and directly transported to designated locations.

Distributing materials: Screw conveyors can also be customized for multi-point unloading to distribute materials to different production lines or processes.

Screw conveyors can be divided into many types according to their design and purpose, including but not limited to the following:

U-type screw conveyor: U-type screw conveyor is a U-shaped trough conveyor, mainly used for horizontal or inclined conveying, and the U-shaped design can help prevent material accumulation and blockage.

Tubular screw conveyor: Tubular screw conveyor is a closed screw conveyor, mainly used for conveying dust and some liquid materials.

Shaftless screw conveyor: The spiral blades of the shaftless screw conveyor are hollow inside, which is suitable for conveying materials that are easy to agglomerate and have high viscosity, such as sludge, slurry, etc.

Cooling screw conveyor: The cooling screw conveyor can cool down the high-temperature materials. Through the cooling device during the conveying process, the temperature of the materials is reduced. It is suitable for conveying heat-sensitive materials.

Double screw conveyor: The double screw conveyor has two spiral blades, which can achieve higher conveying capacity and more uniform material mixing effect. It is suitable for occasions that require large-scale material conveying and mixing.

Vertical screw conveyor: The vertical screw conveyor is used for vertical conveying, which can convey materials from the bottom to the top or the opposite direction.

The advantages of screw conveyors are mainly reflected in the following aspects:

Screw Conveyor provides users with a low-investment, high-return solution with its simple structure and low cost. The equipment adopts a closed conveying design to effectively prevent material leakage and meet environmental protection requirements. Thanks to fewer mechanical parts and a simple working principle, its operation is stable and reliable. At the same time, the screw conveyor is also multifunctional and can simultaneously complete various process requirements such as material conveying, mixing, stirring, cooling, etc., making it a highly cost-effective material handling equipment choice.

The working principle of the screw conveyor is to use the rotation of the spiral blades to push the material along a specific path. When the drive device drives the screw shaft to rotate, friction is generated between the spiral blades and the material, causing the material to be pushed forward and eventually fall into the designated discharge bin.

| Specifications | Spiral diameter (mm) | Pitch(mm) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) | Transport capacity (m³/h) | Speed (r/min) |

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Material size | Material abrasiveness | Recharge Factor | K | A | |||||||

| Powder | Non-abrasive Semi-abrasive | 0.35-0.4 | 0.0415 | 75 | |||||||

| Powder | Grindability | 0.25-0.3 | 0.0565 | 35 | |||||||

| Small pieces a<60mm | Non-abrasive Semi-abrasive | 0.25-0.3 | 0.0537 | 45 | |||||||

| Small pieces a<60mm | Non-abrasive Semi-abrasive | 0.2-0.25 | 0.0645 | 25 | |||||||

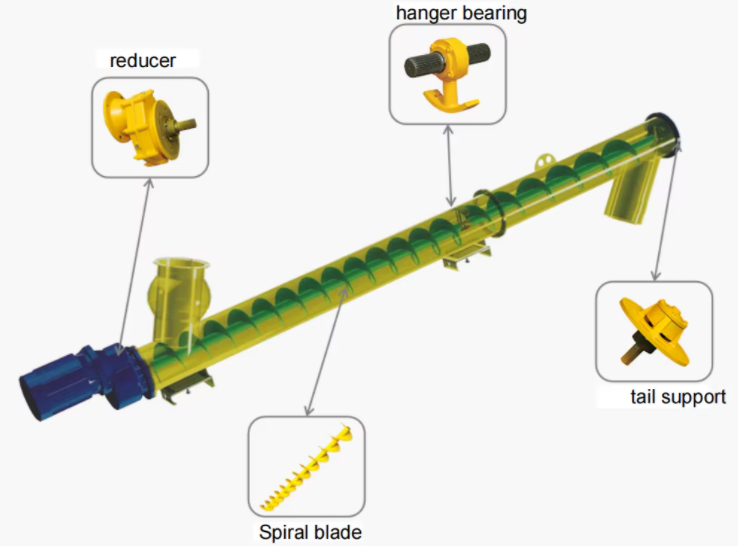

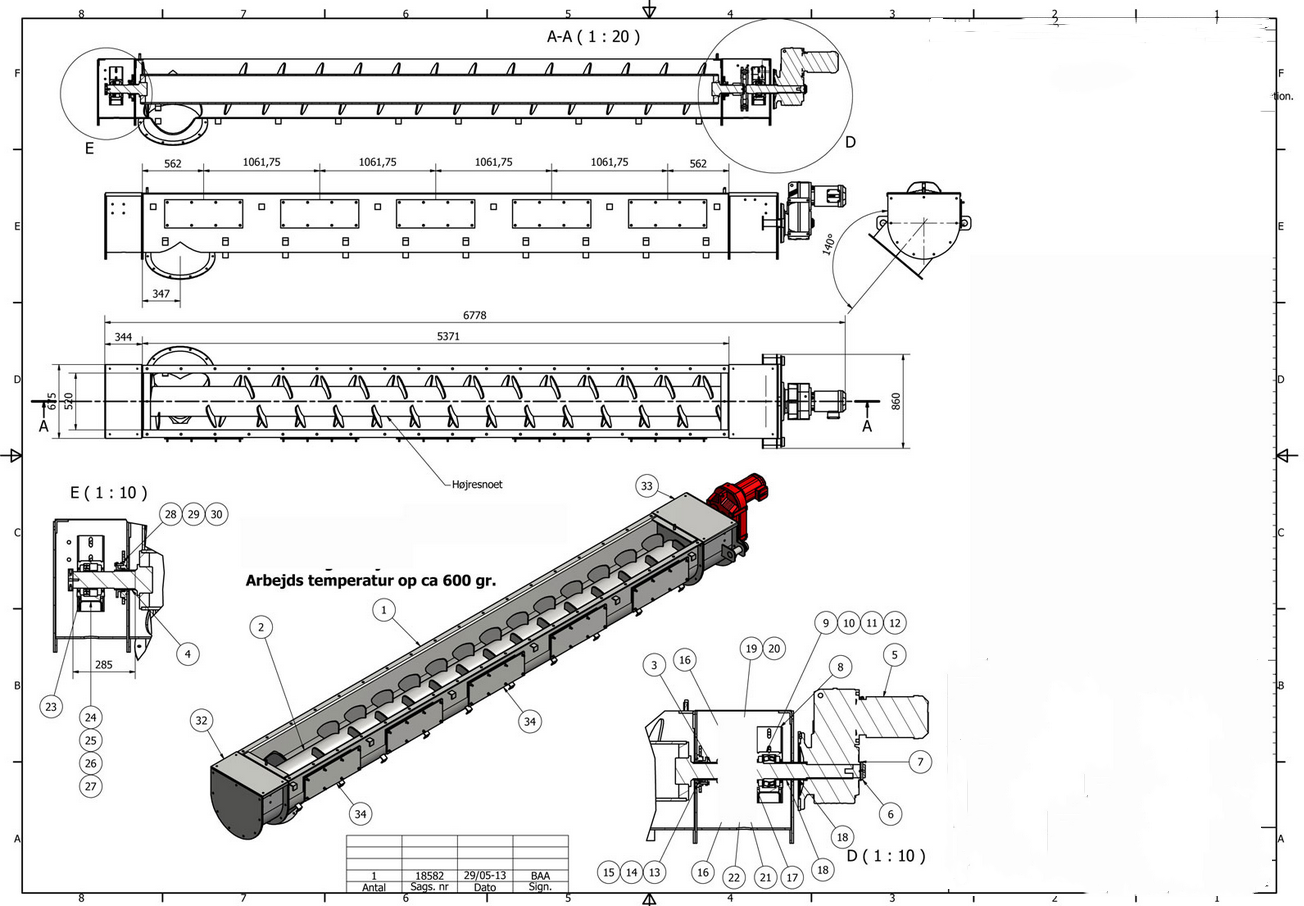

Screw conveyors usually consist of the following main components:

Spiral blades: The spiral blades are usually fixed on the spiral shaft and realize the material transmission by rotation.

Conveying pipeline: The pipeline used to fix and support the spiral blades, usually cylindrical.

Drive device: It includes a motor and a drive system to drive the spiral blades to rotate and realize the material conveying.

Support frame: The structure used to support the conveying pipeline and spiral blades to ensure the stability and safety of the conveyor.

Inlet and outlet: The inlet and outlet for materials, usually designed as an interface connected to the production line or material storage equipment.

Support bearing: Used to support and guide the spiral blades, reduce friction, and ensure the normal operation of the conveyor.

Screw conveyors are versatile conveying equipment suitable for various industrial fields and material conveying scenarios. The following are some common screw conveyor application scenarios:

Food processing: It can be used to convey food raw materials such as flour, powdered sugar, and grains to the next processing line.

Chemical raw material transportation: In the process of chemical production and processing, chemical raw materials are transported to the corresponding production status.

Metallurgical industry: Used to transport ore, coal, coke, and waste slag to metallurgical production.

Building materials industry: Convey cement, sand, stone, and concrete to cement plants, concrete mixing plants, and other places at different angles.

Waste treatment: Used to transport sludge, waste, recycled materials, etc. to waste treatment and resource recovery.

Cosmetics and pharmaceutical industries: Used to convey powder, granular raw materials or products to cosmetic production lines and pharmaceutical production processes.

Our screw conveyors can be customized according to your needs. You can provide your needs and we will provide you with professional services.

According to different usage scenarios and needs, the screw conveyor has three installation methods: horizontal, vertical, and tilted. The angles are as follows:

Horizontal installation: The axis of the screw conveyor is parallel to the ground, and the tilt angle is 0°. This installation method is suitable for conveying materials on the same plane. The conveying process is relatively stable and can effectively avoid material sliding or blockage caused by tilting.

Vertical installation: The axis of the screw conveyor is perpendicular to the ground, with an inclination angle of 90°. It is used to lift materials from low to high, such as conveying materials from the ground to a higher silo.

Inclined installation: The inclination angle is generally between 0° and 45°. Within this angle range, the conveying height of the material can be changed to a certain extent, and the material can be stably conveyed under the action of gravity and screw propulsion.

The limitations of screw conveyors are mainly the following.

| Limitation Aspect | Specific Content | Related Data or Degree Explanation |

| Limited Conveying Distance | As the conveying distance increases, the frictional resistance between the material and the screw blades and the pipe wall increases, the power consumption increases, and the conveying efficiency decreases. | For common small-scale screw conveyors, the conveying distance is mostly within 10 meters. For medium-sized ones, it generally does not exceed 30 meters, and for large-sized ones, it is basically within 50 meters. For every additional 5 meters, the power consumption may increase by 10%-15%, and the conveying efficiency decreases by about 8%-12%. |

| Relatively Small Conveying Capacity | Compared with some large belt conveyors, etc., the conveying capacity of screw conveyors is usually smaller. | Taking the common grain conveying as an example, the conveying capacity of screw conveyors is between 1-30 tons per hour; while the conveying capacity of large belt conveyors can reach several hundred tons or even thousands of tons per hour. |

| High Requirements for Materials | Suitable for conveying powdery, granular and small lumpy materials. For materials with high viscosity, easy caking and high humidity, they are likely to adhere to the screw blades and the casing. | When the material humidity exceeds a certain level (for example, the humidity of powdery materials exceeds 20%, and the humidity of granular materials exceeds 15%), the risk of blockage increases significantly, and the conveying efficiency may decrease by more than 50%. |

| High Power Consumption | Due to the relatively large friction between the material and the screw blades and the casing during the conveying process, the power consumption of screw conveyors is relatively high, and the operation cost is high. | Under the same conveying capacity and conveying distance, the power consumption of screw conveyors is 30%-50% higher than that of belt conveyors. |

We have a professional research, production, sales, and after-sales service team. We have many years of production experience and a professional team, covering a variety of types, including U-type screw conveyors, tubular screw conveyors, shaftless screw conveyors, cooling screw conveyors, double screw conveyors, vertical screw conveyors, etc., which can meet the conveying needs of different customers.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!