Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

In general, the standard diameter series of the corresponding horizontal screw conveyor can be used to determine the vertical screw conveyor

Power: 1-13.5KW

Diameter: 114mm-800mm

Conveying height: ≤6 meters

Application: Bulk material taken from a silo, hopper, conveying or feeding device can be discharged via a vertical screw into a weigh hopper, one or more silos or silos, or another conveyor or conveying system.

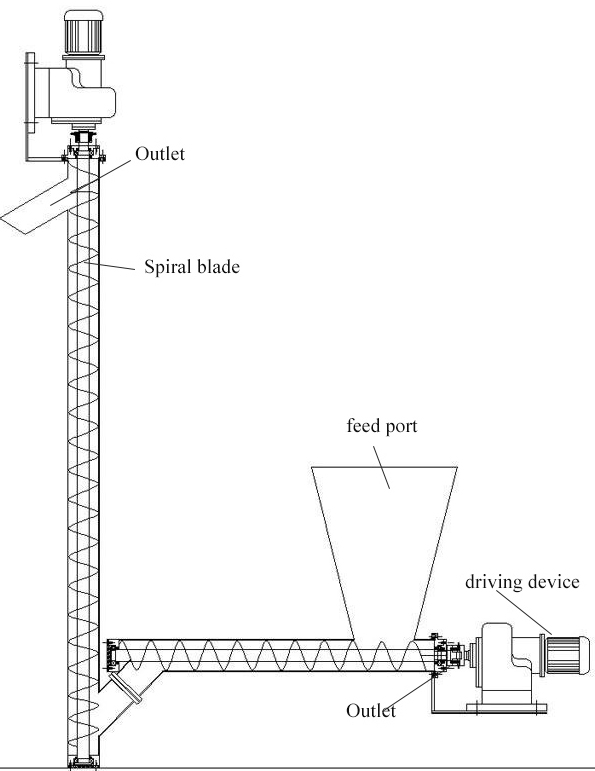

Vertical Screw Conveyor adopts a vertical compact design, supports 0-45° inclination adjustment and 7-meter conveying distance, with a processing capacity of 1-50t/h. It realizes efficient vertical or inclined conveying of powders/particles through high-speed spiral blades (200-400rpm). The equipment is equipped with 304 stainless steel pipe body and wear-resistant lining, which has both corrosion resistance and dustproof characteristics, and is suitable for space-constrained working conditions in industries such as grain, chemical, and building materials.

Vertical Screw Conveyor the powder, granular, non-viscous materials conveyor machine. When the spiral with angular velocity omega rotation, spiral surface material particles under the action of centrifugal force to the shell wall movement, so as to increase the pressure on the shell wall, that is to produce greater friction on the shell wall. When the friction force is greater than the friction force between the material particles and the spiral surface and the force component caused by the self-weight of the material particles sliding along the spiral surface, the material particles and the spiral surface slide and rise along the opposite direction of the spiral track, thus completing the vertical transport.

According to different materials, they can be divided into stainless steel and carbon steel. The following are the characteristics and application scenarios of these vertical screw conveyors of different materials:

1. Stainless steel vertical screw conveyor:

Features: Stainless steel vertical screw conveyor is made of stainless steel, with good corrosion resistance and hygiene, suitable for the transportation needs of food, pharmaceutical and other industries.

Application scenarios: Mainly used for conveying food raw materials, medicines, chemicals and other materials with high hygiene requirements, as well as conveying needs in humid or corrosive environments.

2. Carbon steel vertical screw conveyor:

Features: Carbon steel vertical screw conveyor is made of carbon steel, with good strength and stability, suitable for general industrial transportation needs.

Application scenarios: Mainly used for conveying general industrial raw materials such as particles and powders, suitable for conveying needs of building materials, metallurgy, mining and other industries.

The vertical screw conveyor drives the spiral body to rotate through a motor, and uses the driving force of the spiral body and the assistance of gravity to transport the material vertically along the spiral line, and finally discharge it through the discharge port, realizing an efficient and space-saving material transportation process. It is suitable for the transportation needs of various granular, powdery and block materials.

| Specification | LC160 | LC200 | LC250 | LC315 | |

| Diameter(mm) | 160 | 200 | 250 | 315 | |

| Rotating Speed(r/min) | 450 | 450 | 415 | 380 | |

| Capacity(m3/h) | 10 | 28.5 | 51 | 95 | |

| Conveying Height(m) | 2.5~15 | 2.5~15 | 2.5~15 | 2.5~15 | |

| Motor | Height(m) | 2.5~5.5 | 2.5~5.5 | 2.5~4 | 2.5~4 |

| Model | Y100L2-4 | Y100L2-4 | Y132M1-6 | Y160M-6 | |

| Power | 3KW | 3KW | 4KW | 7.5KW | |

| Height(m) | 6~7 | 6~7 | 4.5~5.6 | 4.5~6 | |

| Model | Y112M-4 | Y112M-4 | Y132M2-6 | Y160L-6 | |

| Power | 4KW | 4KW | 5.5KW | 11KW | |

| Height(m) | 7.5~10 | 7.5~10 | 6~7.5 | 6.5~8 | |

| Model | Y132S-4 | Y132S-4 | Y160L-6 | Y160L-6 | |

| Power | 5.5KW | 5.5KW | 7.5KW | 15KW | |

| Height(m) | 10.5~13.5 | 10.5~13.5 | 8~11 | 8.5~12 | |

| Model | Y132S-4 | Y132M-4 | Y160L-6 | Y180L-6 | |

| Power | 7.5KW | 7.5KW | 11KW | 11KW2台 | |

| Height(m) | 14~15 | 14~15 | 11.5~15 | 12.5~15 | |

| Model | Y160M-4 | Y160M-4 | Y180L-6 | Y180L-6 | |

| Power | 11KW | 11KW | 15KW | 15KW2台 | |

Each component of the vertical screw conveyor plays a very important role. The cooperation of these components enables the vertical screw conveyor to efficiently complete the material conveying task in the vertical direction.

Screw: Mainly responsible for promoting the conveying of materials. The design and material of the screw will affect the conveying effect and wear resistance.

Shaft and bearing: Bearing and supporting the rotation of the screw to ensure the stable operation of the conveyor.

Feed port and discharge port: The feed port is used for loading materials, and the discharge port is used for unloading materials, usually located at the location where they need to be conveyed.

Motor: Used to drive the rotation of the screw and provide power support, usually used in conjunction with the control system.

Support structure: Includes the bracket, base and other parts of the conveyor, used to support and fix the entire conveyor equipment.

Control system: Controls the start and stop, speed and other parameters of the motor to achieve the operation and control of the conveyor.

Vertical screw conveyor has many advantages such as flexible conveying, high efficiency, wide applicability, cost saving, etc. It is one of the important conveying equipment commonly used in many industries.

1. It can be transported vertically in a limited space, saving ground space, especially suitable for production environments with small sites.

2. It can realize multiple conveying directions such as vertical, horizontal, and inclined, and adapt to the conveying needs of different production scenarios.

3. It is suitable for conveying materials in various forms, including granular, powdery, blocky and other types of materials.

4. It can be customized according to different material characteristics and production requirements, with strong adaptability, and can meet the conveying needs of different industries.

Designing a vertical screw conveyor requires calculations of material properties, conveying capacity, structure, drive system, and safety to determine the screw parameters, equipment size, power requirements, and safety performance to ensure that the equipment can efficiently and stably transport materials in the vertical direction.

Vertical screw conveyors are mainly used for material transportation in the vertical direction. It is widely used in many industrial fields. The following are some common application scenarios of vertical screw conveyors:

Grain industry: It is often used to transport materials such as grains, flour, and oatmeal, and can realize material transportation from the ground to the floor.

Chemical industry: Powdered and granular materials in the chemical industry often need to be transported vertically during the production process, and vertical screw conveyors can effectively complete this task.

Building materials industry: In the building materials industry, vertical transportation of granular materials such as cement, lime, and sand usually requires the help of vertical screw conveyors.

Food processing industry: In the food processing industry, powdered and granular food raw materials need to be transported. Vertical screw conveyors can meet these needs and meet hygiene standards.

Mining and metallurgical industry: It is often used to transport ore, coal, limestone and other materials, and can realize material transportation from underground to the ground.

Pharmaceutical and cosmetics industry: In the pharmaceutical and cosmetics industry, powdered and granular raw materials need to be transported, and vertical screw conveyors can meet the special requirements of these industries.

Dahan vertical screw conveyor adopts high-quality materials and advanced production technology, with stable performance and reliable quality assurance. In addition to providing standard models of vertical screw conveyors, we can also customize designs according to customers' special requirements, as well as different materials and different powers to meet the needs of different industries and application scenarios.

The price range of vertical screw conveyor is 500-5000 USD/unit, and the specific price depends on the specification parameters, material configuration and optional functions. The price of small-sized models (Φ150-250mm, 1-5t/h) is 500-1500 USD, and the price of large-sized models (Φ400-600mm, 20-50t/h) is 3000-5000 USD. The basic carbon steel model is economical ($500-2000 USD), while the 304 stainless steel model ($2500-5000 USD) is more suitable for industries with high corrosion resistance requirements such as food and chemical industries. In addition, optional functions such as variable frequency speed regulation and wear-resistant lining will affect the final price. The standard conveying distance of 7 meters is included in the basic quotation, and special working conditions or ultra-long distances require additional calculation. We support non-standard customization and provide maintenance services.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!