Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

As an important food crop, corn plays an important role in the agriculture and food processing industries. In the harvesting, storage and processing of corn, vertical conveyors play an important role as an efficient material transportation equipment.

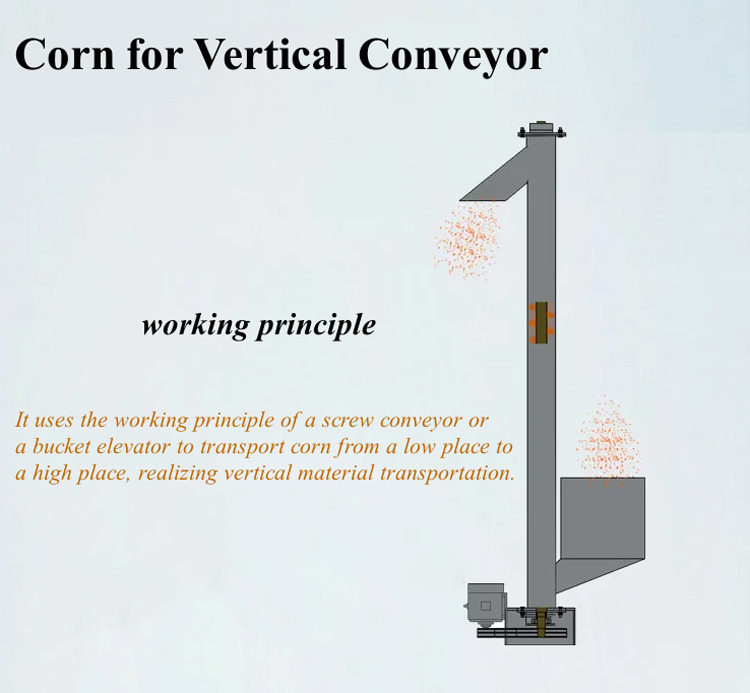

Corn for vertical conveyor is a device used to lift corn and other granular materials vertically. It uses the working principle of a screw conveyor or a bucket elevator to transport corn from a low place to a high place, realizing vertical material transportation. This kind of equipment usually consists of conveying mechanism, motor, transmission device and support structure.

Efficient and energy-saving: Corn for vertical conveyor uses advanced conveying technology to efficiently lift corn to the required height. Its conveying efficiency is high and it can save labor and time costs.

High space utilization: Corn for vertical conveyor can carry out vertical transportation in a limited space, making full use of the vertical space.

Automated operation: Corn for vertical conveyor is usually equipped with an automatic control system to realize automated material transportation. It is easy to operate, just set the relevant parameters, and the equipment can work according to the set requirements.

Easily cope with different process requirements: It can be adjusted according to parameters such as corn transportation volume, lifting height and transportation speed to meet the needs of different production lines.

Corn for vertical conveyor, as an efficient material conveying equipment, has a wide range of applications in the agricultural and food processing industries. It can vertically lift granular materials such as corn to the required height to meet the material transportation needs in different scenarios. The following are several common application scenarios of corn for vertical conveyor:

Corn processing plant: In the corn processing process, corn for vertical conveyor is widely used in corn cleaning, crushing, grinding, drying and other processes.

Corn storage system: In the corn storage system, corn for vertical conveyor is used to transport corn from the ground or low place to the storage equipment or the upper level of the warehouse.

Corn planting base: In corn planting bases, corn for vertical conveyor is often used in seed processing and sowing.

Corn material handling: In addition to the above application scenarios, corn for vertical conveyor can also be used for corn material handling. For example, during corn processing, materials such as corn flour or corn malt need to be transported to different process equipment or storage containers.

Preparation work: First, corn or other granular materials need to be placed in the feed port or hopper to ensure continuous supply of materials.

Start the equipment: Turn on the power of the conveyor and adjust parameters such as conveying speed and lifting height as needed.

Run Conveyor: Start the conveyor's motor or drive to start the conveyor running. Usually, the operation of the conveyor is based on the principle of continuous operation, and the material continues to move upward on the conveyor belt.

Material lifting: The conveyor belt or bucket chain of the conveyor lifts the material from the feed port or feed hopper to the required height. The design of the conveyor belt or bucket chain keeps the material stable during movement and avoids accumulation and dumping.

Unloading: When the material reaches the required height, it can be unloaded through the discharge port or hopper. The discharge method can be selected according to specific needs, such as falling by gravity or using a discharge device.

Stop and maintenance: After completing the material transportation, stop the operation of the conveyor in time, and perform relevant maintenance and cleaning work to ensure the normal operation and life of the equipment.

In short, corn for vertical conveyor has important applications in many fields such as corn processing, warehousing, planting and experimentation. It can improve production efficiency, simplify the material transportation process, and reduce labor costs. It is one of the indispensable equipment in modern agriculture and food processing industries.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!