Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

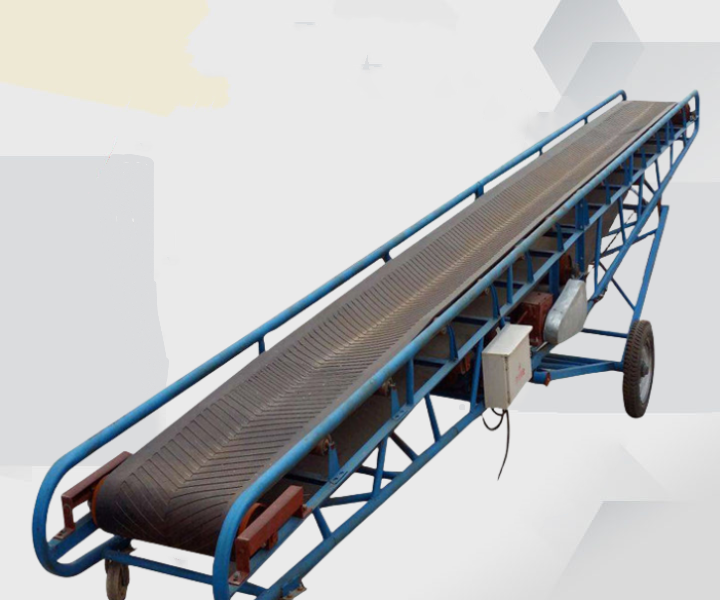

Dirt Conveyor can effectively transport pollutants from one location to another waste treatment station through electric drive.

Transport capacity m³/h: 78-348

Bandwidth Bmm: 500-1400

Belt speed m/s: 0.8-4

Applicable materials: various bulk materials and finished items with bulk density of 500-2500KG/M3

Application areas: metallurgy, mining, coal, ports, power stations, building materials, chemicals, light industry, petroleum, etc.

Dirt Conveyor is a conveying equipment specially used for conveying sludge and solid waste. It can help waste treatment plants and garbage stations solve the problem of garbage transportation. It is used to transport pollutants from point A to point B, which can quickly solve the problem of garbage transportation.

The dirt conveyor is a very important device in conveying pollutants, mainly due to the following advantages

Reduce labor costs: By using a dirt conveyor, you can reduce the work of manual transportation and avoid the harm caused by long-term contact with pollutants.

Improve transportation time: It can directly transport pollutants to the designated place, control the transportation time, and save energy on transportation time costs.

Movable: Generally, there will be a roller design, which can move the conveying position at any time to unload at the same conveying place.

Reduced transportation vehicles: It can replace traditional vehicle transportation and ensure that pollutants can pass through narrow places that cannot be reached by vehicles or other means of transportation.

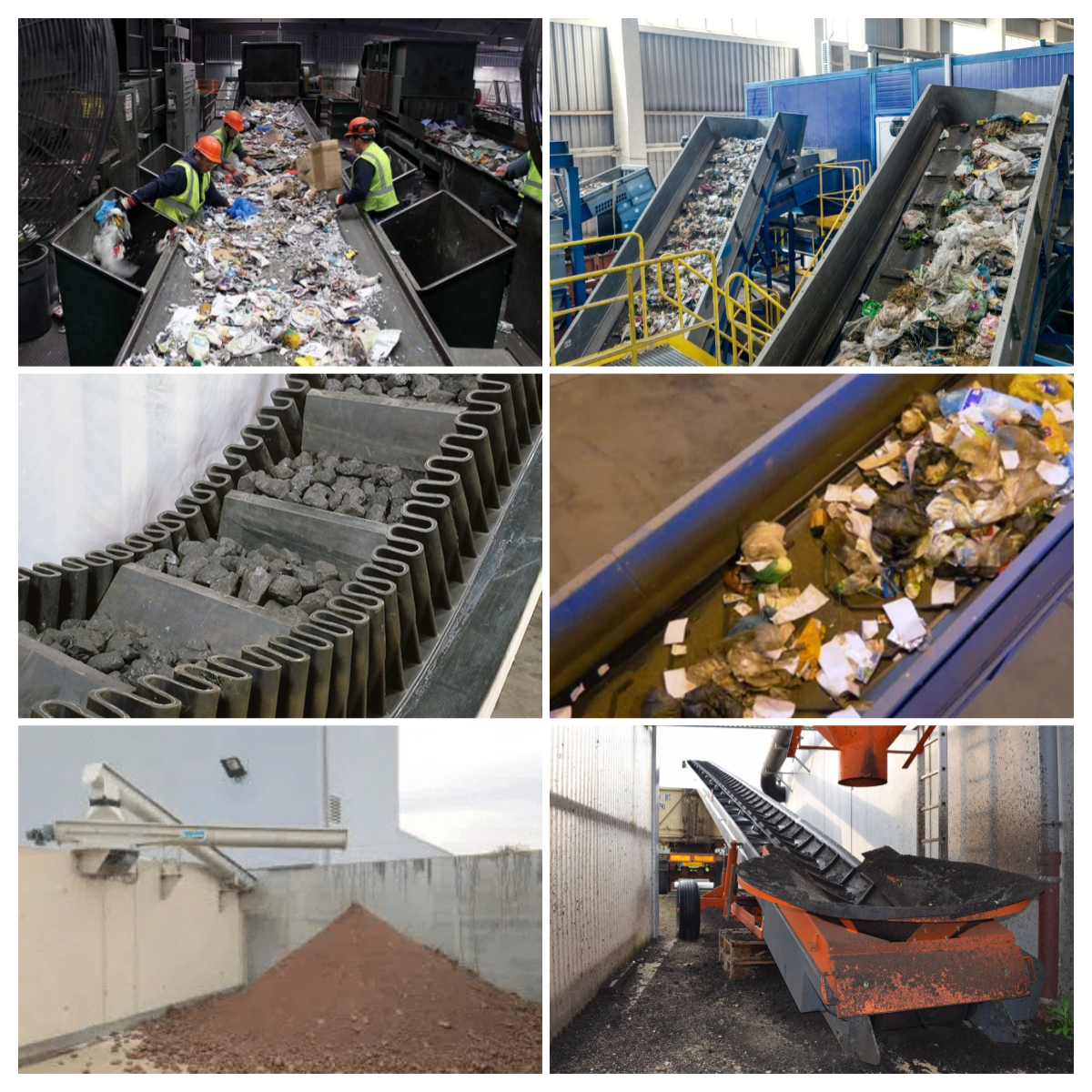

We have different types of conveyors that can transport different types of pollutants, mainly including the following models:

1. Screw conveyor: It mainly uses spiral blades to transport pollutants along the spiral axis to the designated place. It is generally a closed design and can be used for pollutants with relatively large odors and relatively high water content.

2. Scraper conveyor: It scrapes the material from the bottom of the conveyor trough through the scraper and transports it to the corresponding place along the conveyor trough. It can transport some highly viscous dirt and waste.

3. Belt conveyor: It can transport solid waste, ore, coal, etc. There are different forms of transportation, including inclined, horizontal and mobile belt conveyors.

The sewage conveyor can be used to transport various types of pollutants and dirt, including but not limited to the following:

Sewage and sludge: Usually used in sewage treatment plants and sludge treatment plants to discharge some treated sewage and sludge to designated locations.

Solid waste: When some construction waste and domestic waste need to be transported to designated recycling stations during processing, the screw conveyor can quickly and accurately complete this task.

Chemical waste: When the chemical plant is working normally, some harmful chemical waste, waste liquid, and waste residue after treatment need to be transported to a certain location by conveyor for special treatment.

Contaminated soil: The soil mined in the construction of new roads and soil remediation projects needs to be transported to another place. The screw conveyor can complete this task effectively and quickly.

The dirt conveyor drives the conveyor belt through the transmission device to transport the dirt from the loading point to the destination. During the transportation process, the guide device and the cleaning device can ensure that the material runs along the correct path without blockage, and finally the material is safely unloaded to achieve the transportation and treatment of the dirt.

| Loading roller type | Belt speed (m/s) | Band width B (mm) | |||||

| 500 | 650 | 800 | 1000 | 1200 | 1400 | ||

| Transport capacity Q(t/s) | |||||||

| Grooved rollers | 0.8 | 7.8 | 131 | - | - | - | - |

| 1.0 | 97 | 164 | 278 | 435 | 655 | 891 | |

| 1.25 | 122 | 206 | 348 | 544 | 819 | 1115 | |

| 1.6 | 156 | 264 | 445 | 696 | 1048 | 1427 | |

| 2.0 | 191 | 323 | 546 | 853 | 1284 | 1748 | |

| 2.5 | 232 | 391 | 661 | 1033 | 1556 | 2118 | |

| 3.15 | - | - | 824 | 1233 | 1858 | 2528 | |

| 4.0 | - | - | - | - | 2202 | 2996 | |

| Parallel drag roller | 0.8 | 41 | 67 | 118 | - | - | - |

| 1.0 | 52 | 88 | 147 | 230 | 345 | 460 | |

| 1.25 | 66 | 110 | 184 | 288 | 432 | 588 | |

| 1.6 | 84 | 142 | 236 | 368 | 553 | 753 | |

| 2.0 | 103 | 174 | 289 | 451 | 677 | 922 | |

| 2.5 | 125 | 211 | 350 | 546 | 821 | 111 | |

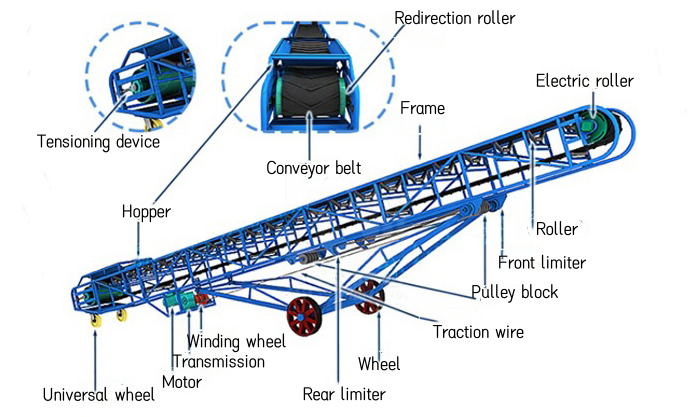

The dirt conveyor is usually composed of multiple components that work together to achieve effective dirt transportation. The following is the general composition structure of the dirt conveyor:

Conveyor belt: used to carry and transport dirt, made of wear-resistant and corrosion-resistant materials.

Transmission device: The transmission device includes a motor, a reducer, a transmission wheel, etc.

Support frame: used to support the conveyor belt and other components to maintain the stability and normal operation of the conveyor belt.

Roller: The roller is installed on the conveying line to support the conveyor belt and reduce friction.

Rollers: Rollers are located on the bottom side of the conveyor belt, supporting the conveyor belt and reducing friction to ensure the normal operation of the conveyor belt.

PLC control system: Used to control the start and stop, speed adjustment, protection, etc. of the conveyor.

When selecting a waste conveyor, you can select it according to the characteristics of the pollutants and the conveying requirements. The following is a recommendation for the selection of waste conveyors based on different types of pollutants:

Solid waste (such as construction waste, waste): For solid waste, it is recommended to choose a belt conveyor model with strong wear resistance and large conveying capacity. It has the characteristics of large conveying volume and stable operation, and is suitable for long-distance transportation.

Sludge treatment: For sludge with high water content, you can choose a corrosion-resistant and anti-clogging shaftless screw conveyor to ensure stable sludge transportation without clogging problems.

Chemical waste: For chemical waste, a screw conveyor may be a suitable choice, because the screw conveyor is suitable for conveying granular and powdery materials, and can effectively transport chemical waste to a designated location.

Contaminated soil: When conveying soil pollution with high viscosity, you can choose a scraper conveyor. If a large amount of contaminated soil needs to be conveyed, it is recommended to choose a belt conveyor.

As a professional sewage conveyor manufacturer, we have strict quality control and testing from material selection, production, and trial machine, and provide different types of conveying equipment such as screw conveyors, scraper conveyors, belt conveyors, etc. for customers to use. The price of our sewage conveyor varies according to the model, specification and customization requirements. Whether it is a sewage treatment plant or a solid waste treatment plant, we can provide you with professional solutions and services. Welcome to contact us to learn more about the price and details of the sewage conveyor!

Dahan Machinery Factory is committed to solving various screw conveyor problems for users. It can conduct on-site inspections of the use scenarios of screw conveyors and can customize screw conveyor equipment with special needs. Dahan Machinery is committed to meeting the needs of users.

Technical support: Dahan Machinery Company has its own team of technical personnel, which can guarantee reasonable solutions for different needs of different users.

Service support: Dahan Machinery provides users with "one-to-one" service support to ensure that users can find someone to solve problems when they find problems. At the same time, the manufacturer provides feedback channels to continuously improve the service direction of Dahan Machinery.

Spot support: Dahan Machinery's online employees produce 12 hours a day to ensure that the products required by users can be solved in a timely manner. Therefore, the manufacturer can ensure that users can solve their transportation problems in the shortest time.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!