Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

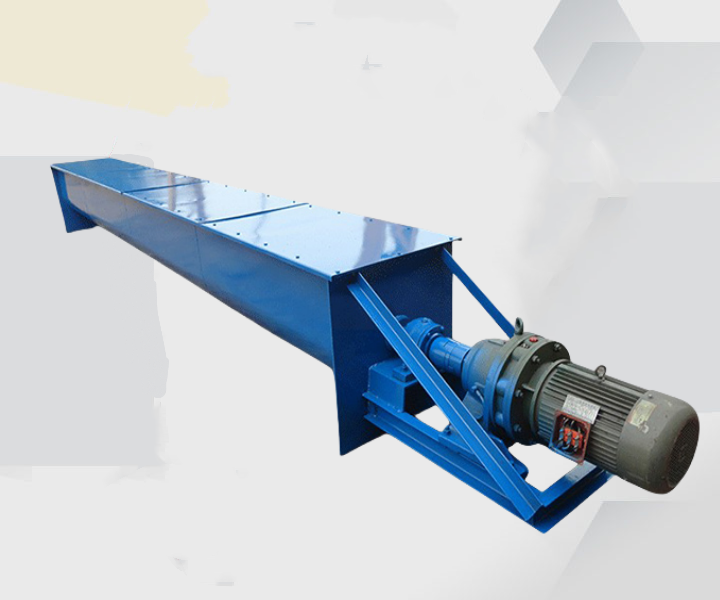

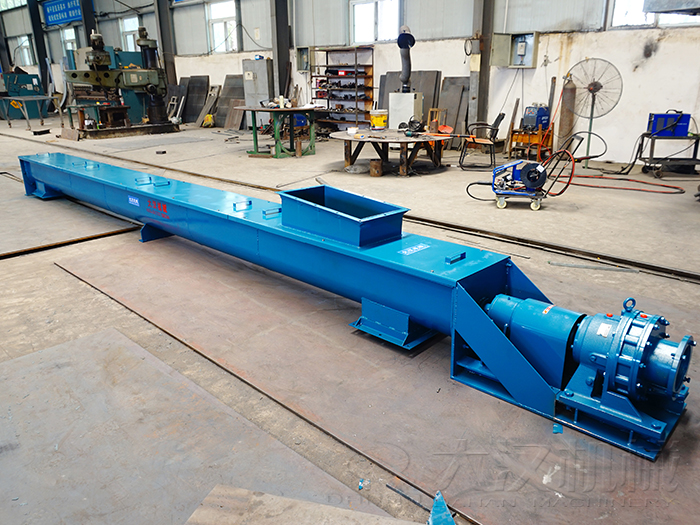

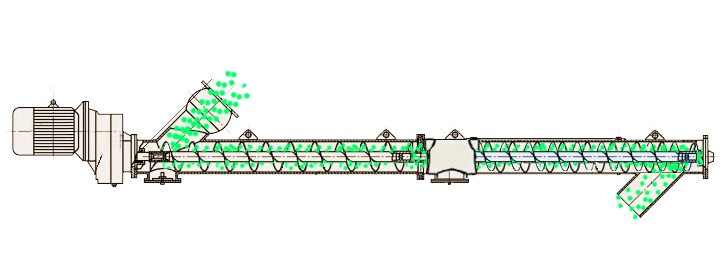

Helix conveyor is also called a screw conveyor. It uses its own screw shaft to push the material forward through the spiral tube, and finally discharges it from the discharge port through continuous rotation. The longest can be up to 30 meters. It is suitable for conveying various materials such as powder, granular, and sludge. There are three materials: carbon steel, stainless steel, and plastic, which can meet different conveying needs.

Using screw conveyors for material transportation can bring many benefits, including but not limited to the following points:

Saving space: It can realize the transportation of a large amount of materials in a limited space.

Strong adaptability: Screw conveyors are suitable for a variety of materials, including granules, powders, block materials, etc., and can also be transported horizontally, inclined or vertically.

Reducing labor: Automated screw conveyors can reduce the workload of manual handling and conveying materials.

Reducing material loss: The conveying process of screw conveyors is relatively stable and a closed design can be selected, which can reduce material loss and overflow.

Simultaneous transportation: When we convey different types of products, we can use multiple conveyors to transport materials in multiple directions.

Helix conveyors can be divided into many types according to different conveying requirements and material characteristics.

1. Shaftless screw conveyor: Its spiral blades are directly in contact with the inner wall of the casing, and there is no central shaft. This design makes it particularly suitable for conveying materials with high viscosity and easy entanglement.

2. Inclined screw conveyor: Its spiral pipe is in an inclined state. By changing the inclination angle, the conveying speed and height of the material can be adjusted.

3. Flexible screw conveyor: Its spiral pipe is made of tendon material and can be bent at will to change the conveying direction. It is usually used to convey grains and sand.

4. Double-axis screw conveyor: It has two spiral shafts rotating in the same or opposite direction. Through the joint action of the two spiral shafts, it can achieve multiple functions such as mixing, stirring, and conveying of materials.

Screw conveyors are usually composed of the following basic components:

Spiral shaft blades: The spiral blades are usually in a spiral shape, and can have different pitches and spiral diameters according to different conveying requirements.

Conveying pipeline: It is used to accommodate the spiral blades and convey materials, and is generally circular.

Drive device: Provides power to drive the spiral blade to rotate and promote material transportation.

Feed port and discharge port: The feed port is used for material input, and the discharge port is used for material discharge. These ports are usually located at both ends of the conveyor and can be designed and positioned as needed.

The material is transported forward along the spiral shape of the conveying pipe along the spiral blade. During the conveying process, the spiral blade exerts an extrusion force on the material, forcing the material to move along the direction of the spiral blade. Under the combined action of friction and extrusion, the material moves forward along the spiral line of the spiral blade and is finally discharged from the discharge port.

Good sealing: The material is conveyed in the closed trough of the screw conveyor, and the spiral shaft and the trough are sealed by a sealing device, which can effectively prevent dust from flying and material leakage.

High conveying efficiency: The screw conveyor continuously conveys materials through the rotation of the spiral blade, and its conveying speed can be adjusted according to actual needs.

Flexible and diverse conveying direction: A variety of materials can be conveyed in horizontal, inclined or vertical directions. For materials of different properties, as long as the shape, pitch and speed of the spiral blade are adjusted, a good conveying effect can be achieved.

Ability to convey a variety of materials: Powdered, granular and small block materials can be conveyed. For materials of different properties, it can transport cement with good fluidity, dry sand, as well as feed raw materials with a certain viscosity.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Screw diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Conveying capacity Q=0.33 (m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| Power Pd 1=10m (KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 9. | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Conveying capacity Q=0.33 (m3/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Conveying capacity Q=0.33 (m3/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 6 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Conveying capacity Q=0.33 (m3/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

When choosing to use a screw conveyor or a portable flexible conveyor, we need to consider the characteristics and conveying requirements of different types of materials. The following is a selection guide for the two conveyors based on material classification:

Screw conveyor: Suitable for conveying powdered materials such as fine powder and powder, and can be transported efficiently and stably.

Portable flexible conveyor: The length can be adjusted as needed, suitable for short distances and occasions where the conveying position needs to be changed frequently.

Screw conveyor: Suitable for conveying granular materials such as grains, granular fertilizers, etc., with strong stability.

Portable flexible conveyor: Suitable for granular material scenes that require flexible adjustment of length and angle.

Screw conveyor: You can choose a shaftless screw conveyor, which can effectively avoid the problem of material blockage.

Portable flexible conveyor: Suitable for conveying materials with relatively low viscosity, high flexibility, easy to clean and maintain.

Screw conveyor: Suitable for conveying large bulk materials such as wood chips and ores.

Portable flexible conveyor: Suitable for conveying bulk materials with demanding scenes and small conveying volumes.

Screw conveyor, as a general and multifunctional material conveying equipment, is widely used in various industrial fields.

Grain processing: Convey grain raw materials to a designated location for the next step of processing and generation.

Chemical industry: In the chemical industry, some powder raw material processing is required for work, and the screw conveyor can complete this task stably and safely.

Building materials: We usually use cement, lime, sand, gravel and other building materials in construction. The screw conveyor can use the function of the spiral shaft to transport the raw materials to the designated place.

Mining and metallurgy: We can use the screw conveyor to process the mined ore, saving vehicle resources and easily adapting to different environments.

Waste treatment: Domestic garbage, sludge and sewage can be transported to a certain recycling place through the spiral pipe.

We have a professional team in material selection, design, production, trial machine, delivery, etc., to ensure that the customer's products can have the best performance when leaving the factory, and can provide screw conveyors of different specifications and models. There are professional after-sales personnel who can provide one-to-one guidance to ensure your after-sales service.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!