Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

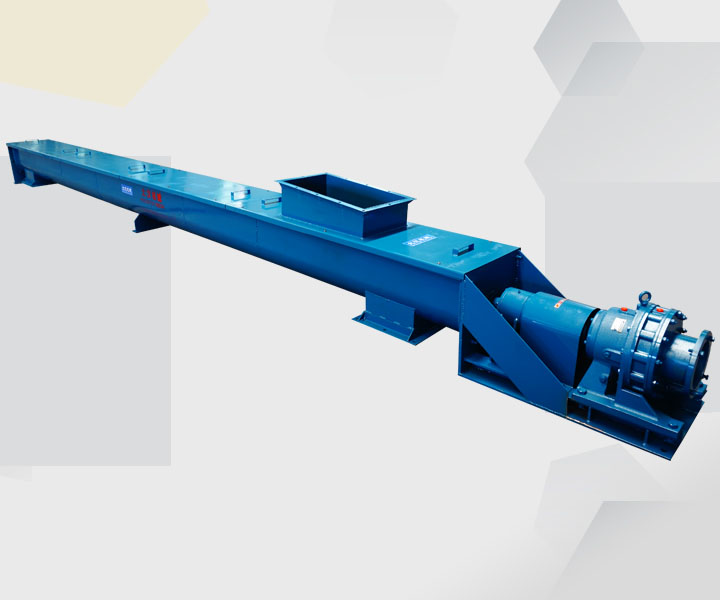

Horizontal Screw Conveyor conveys small particles/powder/small block materials horizontally or inclined at 20°, with low speed, can load and unload materials at any point, and the length of the middle section can be customized.

Price: $500.00 - $20,000.00/Set Chat Now

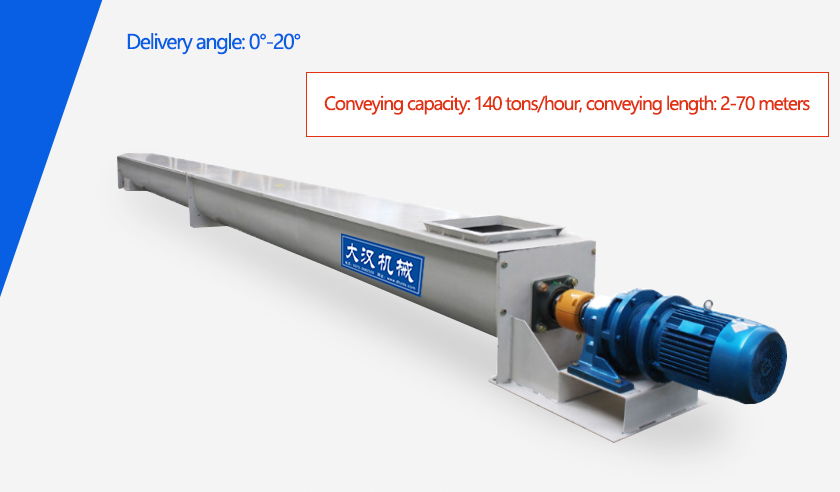

Spiral diameter: 100-1250mm

Conveying length: 3-70 meters

Delivery capacity: 9-140t/h

Motor power: 1.6-73kw

Horizontal Screw Conveyor is a non-foundation fixed screw conveyor, which can continuously and evenly convey various loose materials horizontally or slightly inclined (below 20º). According to the functional structure of the machine body, it can be roughly divided into three parts: the head section, the middle section and the tail section. The lengths of the head section and the tail section are basically fixed, and the length of the middle section can be selected according to actual needs. The feed port and the discharge port do not have to be installed at the end and the end, the entire conveying length can be loaded and unloaded, and the number of the feed port and the discharge port can be set according to the needs. Its rotation speed is lower than that of vertical conveyors, and its conveying distance is generally not more than 70 meters. During the conveying process, the functions of mixing, stirring or cooling can be completed at the same time.

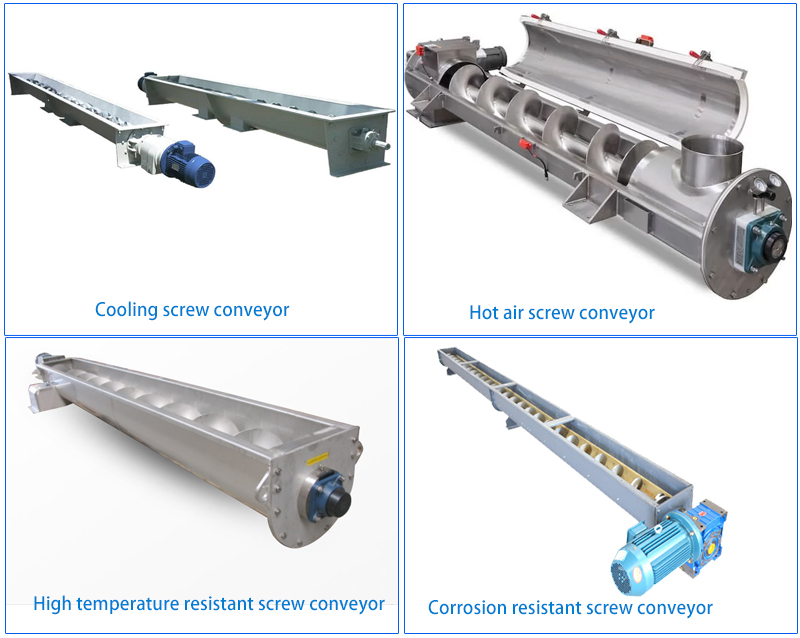

Horizontal screw conveyors can be divided into many types according to their structure and function. Some common types include:

Cooling screw conveyor: used to cool high-temperature materials. Usually, the materials are cooled by external cooling medium during the conveying process.

Hot air screw conveyor: suitable for heating materials. The materials are heated by built-in heating devices. They are commonly used in drying or heating processes.

High temperature resistant screw conveyor: specially designed for conveying high-temperature materials. It has the characteristics of high temperature resistance and wear resistance. It is widely used in metallurgy, building materials and other industries.

Corrosion resistant screw conveyor: designed for the needs of conveying corrosive materials, usually using corrosion-resistant materials or special surface treatment.

Horizontal Screw Conveyor can be used for powdery, granular and small block materials in various industries for conveying, metering, cooling, mixing, separating, compacting and loading. Specific materials include: flour, cement, concrete, sludge, mud cake, Fly ash, household garbage, grain, clay, etc.

Food processing industry: used for conveying and mixing flour and grain, playing a key role in food processing production lines.

Building materials industry: used for conveying, metering and cooling cement and concrete, suitable for places such as concrete mixing stations.

Energy industry: used for conveying and separating fly ash, playing a role in places such as coal-fired power plants.

Waste disposal industry: used for conveying and treating domestic waste, helping to improve waste treatment efficiency.

Ceramics and building materials industry: used for conveying and treating clay, commonly seen in production lines of ceramics, building materials and other industries.

1. It can be conveyed horizontally or inclined, and the conveying inclination angle is less than 20°.

2. The functional structure of the body can be roughly divided into three parts: the head section, the middle section and the tail section. The lengths of the head section and the tail section are basically fixed, and the length of the middle section can be selected according to actual needs.

3. The feed port and the discharge port do not need to be installed at the end and the end, the entire conveying length can be loaded and unloaded, and the number of feed ports and discharge ports can be set according to the needs.

4. The overall seal is strict, which can prevent dust from flying and reduce environmental pollution.

5. It is convenient for multi-point loading and unloading, and can complete the mixing, stirring or cooling function during the conveying process.

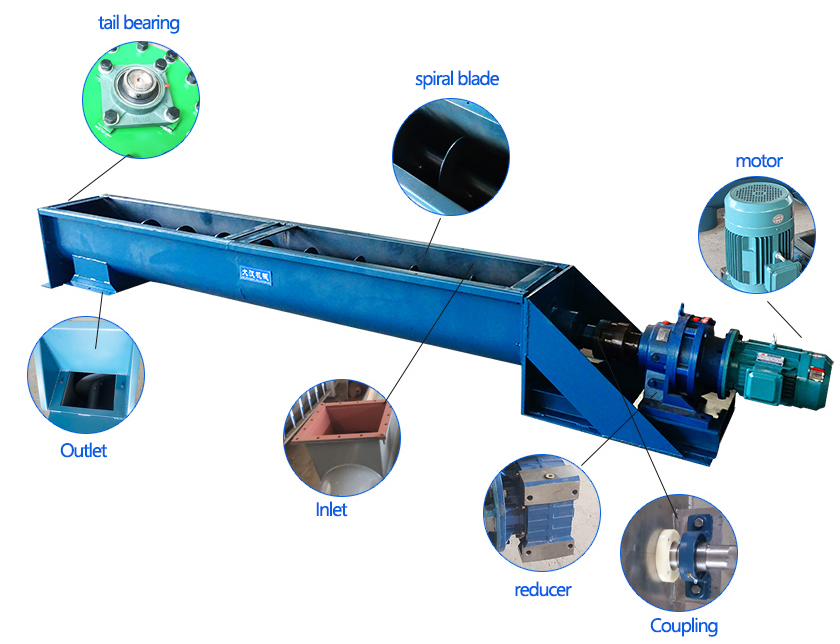

The Horizontal Screw Conveyor consists of a driving device, a head assembly, a casing, a shaftless screw body, a tank liner, an inlet, an outlet, a cover (if necessary), a base, etc.

1. Driving device: Cycloidal pin wheel reducer or shaft-mounted hard-toothed gear reducer is used. When designing, the driving device should be installed at the end of the discharge port as much as possible, so that the spiral body is in a tensioned state during operation.

2. The head is equipped with a thrust bearing, which can withstand the axial force generated when conveying materials.

3. Chassis: The casing is U-shaped or O-shaped, with a rainproof cover on the top, made of stainless steel, carbon steel or glass fiber reinforced plastic.

4. Spiral body: the material is stainless steel or carbon steel.

5. Lining plate of tank body: the material is wear-resistant plastic plate or rubber plate or cast stone plate, etc.

6. Inlet and outlet: There are two types of square and round. Generally, the form of inlet and outlet is determined by the user.

The Horizontal Screw Conveyor is used to convey bulk materials from one part of the process to another. When the screw shaft rotates, due to the gravity of the material and the friction generated by the wall of the tank, the material can only be pushed by the blades. Moves forward along the bottom of the conveyor trough.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

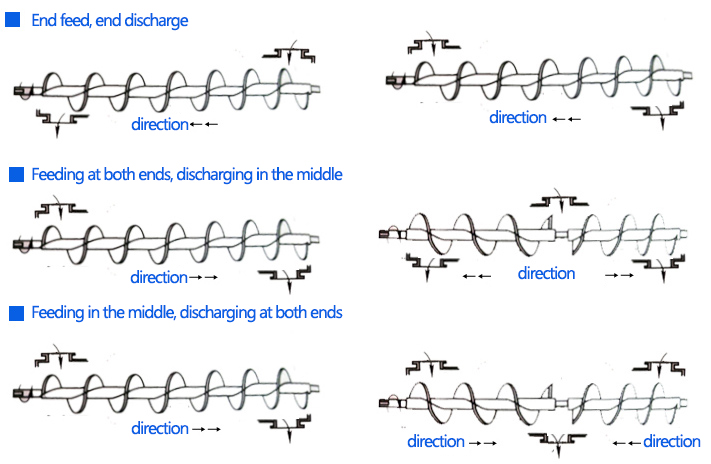

According to different layout requirements, the horizontal screw conveyor can adopt the following layout design:

End feed, end discharge: In this layout, the material enters from one end of the conveyor, rotates through the spiral of the conveyor, and finally discharges from the other end. It is common in situations where materials need to be transported from one work area to another.

Feeding at both ends, discharging in the middle: In this layout, materials can be fed from both ends of the conveyor at the same time, and the middle position is used to discharge materials. It is suitable for situations where materials from multiple sources need to be mixed before discharging, and the material mixing function can be realized.

Feeding in the middle, discharging at both ends: In this layout, materials enter from the middle position of the conveyor and are then discharged from both ends. It is suitable for situations where materials from one source need to be transported to two different locations separately, and the diversion of materials can be realized.

Dahan Screw Conveyor is a manufacturer specializing in the production of horizontal screw conveyors, dedicated to providing high-quality and efficient conveying solutions for various industries. Our horizontal screw conveyors can be used for various operations such as conveying, metering, cooling, mixing, separation, compacting, loading, etc. of various powdered, granular, and small block materials. We are able to provide customized design and manufacturing solutions based on the specific needs of customers to ensure that the equipment fully meets customer requirements. We have a professional after-sales team that can respond to customer needs in a timely manner, provide comprehensive after-sales support and maintenance services, and ensure the long-term and stable operation of customer equipment. If you are looking for a reliable horizontal screw conveyor manufacturer, please contact us, we will wholeheartedly provide you with quality products and services.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!