Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Powder hose conveyor is used to convey various powder materials, such as powder raw materials, chemicals, food powder, medicine, etc. The powder materials are conveyed through the hose, the conveying pump provides pressure to drive the material flow, and the control system monitors and adjusts the conveying process.

Voltage: 220~580

Voltage: 220 - 580 V

Capacity: 2t/h - 25 T/h

Length: 3 - 30Meter

Applicable Industries: Food, Chemical, Construction, Medicine, Agriculture

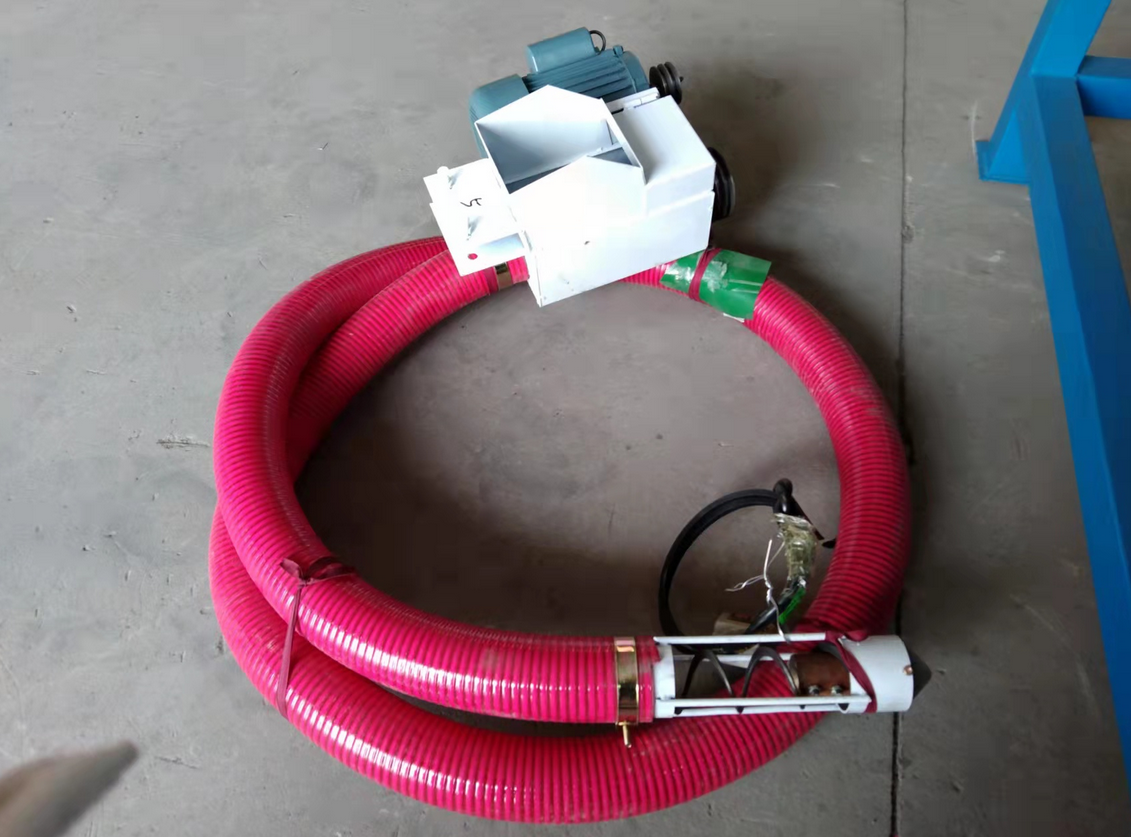

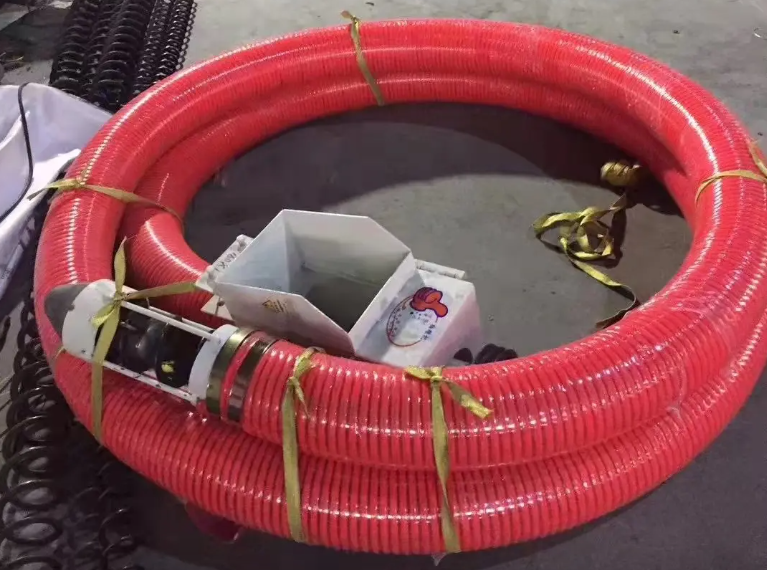

Powder Hose Conveyor is a conveying device that uses a flexible hose as a conveying pipeline and drives the material to flow in the pipeline by pneumatic or mechanical means. It can be used to convey different types of powders and adapt to different scenarios. Compared with traditional conveyors, it is more suitable for use in places where the working scene is unstable.

Powder hose conveyor is a device specially used to convey powder materials. Its design structure directly affects the conveying efficiency, equipment stability and service life.

Conveying hose: connects the feed port and the discharge port, responsible for the conveying of powder. Commonly used wear-resistant and antistatic food-grade PU (polyurethane) or PVC materials, stainless steel hoses can be used in special occasions.

Filter system: separates air and powder to prevent powder from entering the vacuum pump and avoid dust leakage into the environment.

Feeding device: sucks powder from the storage container into the conveying hose. The shape and size are designed according to the characteristics of the powder to ensure efficient suction.

Discharging device: discharges powder from the conveying hose to a specified location. Used to completely discharge powder from the hose to avoid residue.

Control system: controls the start, stop, conveying volume and other operations of the equipment.

The powder hose conveyor uses the principle of aerodynamics to form a negative pressure or positive pressure environment in the hose through the airflow generated by the fan, thereby realizing the conveying of powder materials. When in negative pressure mode, the material is sucked into the hose from the feed port and transported to the destination along the hose under the airflow; in positive pressure mode, the material is pressed into the hose from the silo and other feeding devices by compressed air for conveying.

The advantages and characteristics of the powder hose conveyor are mainly as follows.

Flexible and convenient installation and layout: Made of flexible materials such as polyurethane, rubber, etc., it has good flexibility and can be flexibly arranged whether in narrow workshop passages or production lines that require frequent adjustment of the conveying route.

Efficient dust prevention, environmental protection and energy saving: The closed conveying structure effectively avoids the leakage and dust flying of powder materials during the conveying process, greatly improves the working environment, and reduces the waste of materials compared to some open conveying equipment.

Low wear and high-precision conveying: Due to the smooth inner wall of the hose, the friction between the material and the pipe wall during the conveying process is small. This can maintain the original characteristics of some powder materials that are easy to wear and have high requirements for particle integrity, such as pharmaceutical powders, electronic material powders, etc., to the greatest extent and reduce material loss.

Maintain material quality: Since the material is not contaminated by the outside world during the conveying process in the hose, the quality and purity of the material can be effectively maintained.

The powder hose conveyor is a highly flexible and adaptable equipment that can convey various types of powder materials. Its application range is wide and covers multiple industries.

Chemical powder: pigments, dyes, resins, plastic particles, catalysts, fertilizers, pesticides, chemical powders usually have high fluidity, but some materials may be corrosive or toxic, and corrosion-resistant hoses and filters need to be selected.

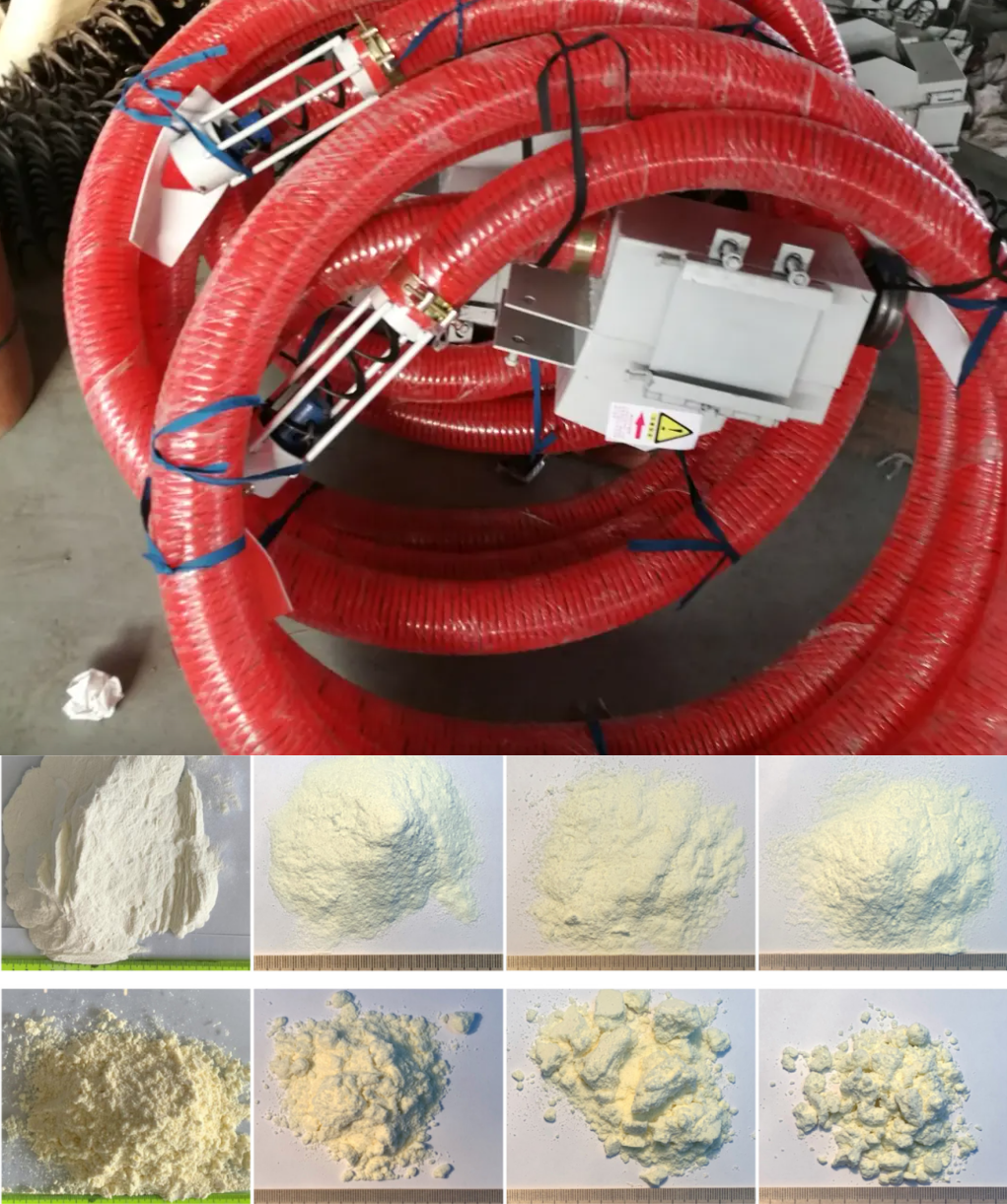

Food powder: flour, sugar, milk powder, coffee powder, seasoning, starch, protein powder, food powder has high requirements for hygiene, and food-grade hoses and filters need to be used, and the equipment must be easy to clean.

Pharmaceutical powder: pharmaceutical raw materials, intermediates, finished drugs, Chinese medicine powder, vitamins. Pharmaceutical powder has extremely high requirements for purity and hygiene, and requires aseptic design and equipment that meets GMP standards.

Building material powder: cement, fly ash, gypsum powder, lime powder, ceramic powder. Building material powder usually has coarse particles and may have high abrasion resistance. Wear-resistant hoses and filters need to be selected.

Metal powder: aluminum powder, copper powder, iron powder, magnesium powder, tungsten powder, etc. Metal powder has a high density and may be flammable and explosive. Anti-static and explosion-proof design are required.

Other powders: carbon powder, graphite powder, rubber powder, wood powder, talcum powder, etc. These powders may have special physical or chemical properties, and equipment configuration needs to be selected according to specific characteristics.

|

Model |

Length (Meters) |

Pipe diameter |

Loading Capacity (t/h) |

Motor phase power(kw) |

Installation |

Structure |

|

RLS100 |

4 meter |

100mm |

5-8 |

Single phase-3kw |

Vehicle mounted |

Steel screw blade inside |

|

5 meter |

||||||

|

6 meter |

||||||

|

8 meter |

||||||

|

..... Customized |

||||||

|

RLS120 |

4 meter |

120mm |

10-15 |

Three phase-4KW |

Vehicle mounted |

Steel screw blade inside |

|

5 meter |

||||||

|

6 meter |

||||||

|

8 meter |

||||||

|

..... Customized |

Powder hose conveyor has clear requirements for powder humidity. Excessive humidity will seriously affect the conveying efficiency, equipment operation stability and material quality. Generally speaking, the humidity of powder should be controlled below 5%. The specific humidity requirements should be considered comprehensively according to the material characteristics of the powder, the conveying distance, the equipment configuration and other factors.

Ideal humidity range: For most powder materials, the humidity control of 1%-3% is the most ideal, which can ensure that the material has good fluidity and conveying efficiency. If the humidity exceeds 5%, the powder is easy to clump and adhere, resulting in poor conveying or even blockage.

Humidity requirements for special materials: For some powders with strong hygroscopicity (such as starch, milk powder, etc.), the humidity should be controlled below 2% to avoid material agglomeration or deterioration.

For powders with larger particles or better fluidity (such as plastic particles, sand powder, etc.), the humidity can be appropriately relaxed to about 5%, but it is still necessary to avoid excessive humidity.

Impact of humidity on conveyor

Conveying efficiency: Excessive humidity will reduce the fluidity of the powder, resulting in slower conveying speed and even blockage. High-humidity powder is easy to form an adhesion layer on the inner wall of the hose, increasing the conveying resistance and reducing the efficiency of the equipment.

Equipment wear: Powders with excessive humidity will increase the wear of the hose and the filter system and shorten the service life of the equipment. If the powder is corrosive, high humidity will accelerate the corrosion of the equipment.

Material quality: In the food, medicine and other industries, excessive humidity may also cause microbial growth and affect health and safety.

The following factors need to be considered when selecting a suitable powder hose conveyor.

Material characteristics: Including material particle size, density, fluidity, humidity, viscosity, corrosiveness, etc., materials with different characteristics require different types of conveyors and conveying hoses.

Conveying volume: Select the appropriate conveying volume according to production needs to avoid over-large or under-sized equipment.

Conveying distance and height: Conveying distance and height will affect the power and configuration of the equipment, and need to be selected according to actual conditions.

Working environment: Consider factors such as temperature, humidity, explosion-proof requirements, etc. of the working environment, and select suitable equipment models and materials.

Dahan Machinery Co., Ltd. focuses on the research and development and manufacturing of powder hose conveyors. It has many years of industry experience and its products are known for their high efficiency, stability and durability. The company provides customized solutions and is widely used in chemical, food, medicine and other fields. It is committed to providing customers with high-quality equipment and perfect after-sales service. It is a reliable partner in the field of powder conveying.

Powder hose conveyors can convey various types of powder materials, including chemical, food, pharmaceutical, building materials, metal and other fields. In practical applications, it is necessary to select appropriate equipment configuration and conveying parameters according to the characteristics of the powder, such as particle size, density, humidity, viscosity, corrosiveness, etc. Through reasonable design and operation, powder hose conveyors can efficiently and safely complete the conveying tasks of various powder materials to meet the needs of different industries.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!