Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Diameter: 100mm-1250mm

Capacity: 458m³/h

Length: 2-70 meters

Angle of Inclination: 0-90°

Customized: shaft/shaftless, tubular/U-shape, single shaft/double shaft

Application: Used to transport large quantities of granular solids (e.g., powders, granules, granules), semi-solids, liquids, and even non-flowing materials from one point to another, including concrete, dry sand, gypsum, fly ash, grain, etc.

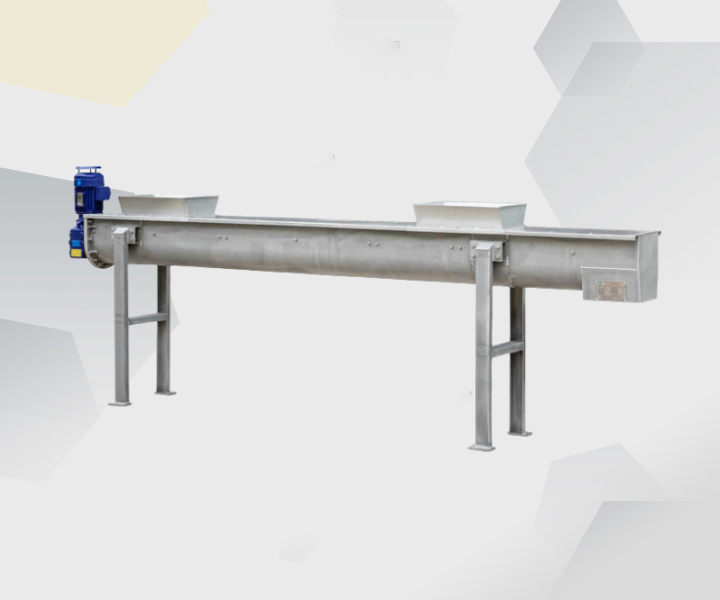

Screw Conveyor Belt For Transferring, also known as screw conveyor or auger conveyor, is a continuous conveying equipment that pushes materials through rotating spiral blades. It is mainly used in grain, chemical, building materials, metallurgy and other industries. It is suitable for horizontal or inclined conveying of granular, powdered and small block materials. As a source manufacturer, we can also provide customers with conveying equipment of different types and materials.

We can provide different types of conveyor belts for different customers.

U-type screw conveyor: open trough, easy to maintain, mainly used in grain, feed, fertilizer, granary feeding, feed factory ingredients and other industries.

Tube screw conveyor: fully enclosed structure, dustproof and leakproof, can be used to convey powdered materials (cement, flour) chemical plants, food processing

Flexible screw conveyor: hose + flexible screw, adapt to complex paths, can convey light powder, milk powder, additives.

Double screw conveyor: two screws run synchronously, mixing + conveying in one, mainly used in feed, building materials, compound fertilizer production, concrete mixing station.

The advantages of Screw Conveyor Belt For Transferring are mainly as follows.

Conveying a variety of materials: Whether it is powdered flour, cement, granular grain, ore, or blocky, sticky materials, such as dough in food processing, sticky raw materials in chemical production, etc., stable conveying can be achieved.

Good sealing: The fully enclosed casing structure gives the spiral conveyor belt excellent sealing, which is especially important when conveying toxic, harmful, flammable, explosive, volatile or highly hygienic materials.

Stable conveying: The continuous rotation of the spiral blades makes the material conveying process smooth and uniform, reduces material impact and vibration, and effectively reduces the breakage rate and ensures the integrity of fragile materials such as glass product raw materials, puffed food particles, etc. for fragile materials.

High space utilization: It can be flexibly designed as horizontal, inclined or vertical conveying mode according to the site space and process layout, and can complete material conveying tasks in narrow spaces, especially suitable for the renovation of old factories or production workshops with limited space.

Screw Conveyor Belt For Transferring is applied in different industries with its own advantages.

Food and beverage industry: Screw conveyor belts undertake key tasks such as raw material transportation, semi-finished product transfer and finished product pre-packaging transportation.

Chemical industry: Screw conveyor belts can transport powdered or granular chemical raw materials from storage bins to reactors. During the transportation process, special design can be used to achieve quantitative feeding and accurately control the proportion of reaction materials.

Building materials industry: In cement, lime, gypsum and other building materials production enterprises, screw conveyor belts are used for material transportation, storage and batching. Raw materials such as cement clinker and limestone powder are transported from the crusher to the grinder, and then the ground finished materials are transported to the storage warehouse or packaging workshop.

Sludge treatment: The sludge in the sedimentation tank can be transported to the dehydration equipment for treatment; in the garbage treatment plant, the sorted recyclable materials or garbage are transported to the corresponding treatment equipment. Its strong adaptability can cope with the transportation needs of complex materials such as sludge and garbage.

The composition structure of the screw conveyor belt is relatively simple, but the coordination between the various components is essential.

Conveyor belt: responsible for carrying and transporting materials. It is usually made of wear-resistant materials to ensure that it can withstand the weight and friction of the materials during the conveying process.

Spiral blades: fixed on the conveyor belt, responsible for pushing the materials forward. The spiral shape design allows the materials to effectively utilize space during the conveying process and reduce the accumulation and blockage of materials.

Drive device: The motor drives the spiral blades to rotate through the transmission device, thereby pushing the materials along the conveyor belt. The power and speed of the drive device can usually be adjusted according to specific conveying needs.

Support frame: Provide mechanical structural support to maintain the stability and correct position of the conveyor belt and other components.

Feed port and discharge port: The feed port is used for the entry of materials, and the discharge port is used for the discharge of materials. Their design should ensure that the materials are not easy to leak during the conveying process.

When the drive device is started, the motor drives the reducer to operate, which in turn rotates the central shaft, and the spiral blades installed on the central shaft rotate accordingly. During the rotation of the spiral blade, the material is acted upon by the thrust of the blade and moves forward in a spiral shape along the inner wall of the casing, eventually reaching the designated position.

|

Model |

Diameter |

Pitch |

Rotating speed |

Capacity |

Rotating speed |

Capacity |

Rotating speed |

Capacity |

Rotating speed |

Capacity |

|

|

Small |

100 |

100 |

100 |

140 |

2.2 |

112 |

1.7 |

90 |

1.4 |

71 |

1.1 |

|

125 |

125 |

125 |

125 |

3.8 |

100 |

3 |

80 |

2.4 |

63 |

1.9 |

|

|

160 |

160 |

160 |

112 |

7.1 |

90 |

5.7 |

71 |

4.5 |

56 |

3.6 |

|

|

200 |

200 |

200 |

100 |

12.4 |

80 |

9.9 |

63 |

7.8 |

50 |

6.2 |

|

|

Small |

250 |

250 |

250 |

90 |

21.8 |

71 |

17.2 |

56 |

13.6 |

45 |

10.9 |

|

315 |

315 |

315 |

80 |

38.8 |

63 |

30.5 |

50 |

24.2 |

40 |

13.4 |

|

|

400 |

400 |

355 |

71 |

62.5 |

56 |

49.3 |

45 |

38.6 |

36 |

31.7 |

|

|

Large |

500 |

500 |

400 |

63 |

97.7 |

50 |

77.6 |

40 |

62 |

32 |

49.6 |

|

630 |

630 |

450 |

50 |

138.5 |

40 |

110.8 |

32 |

88.6 |

25 |

69.3 |

|

|

800 |

800 |

500 |

40 |

198.5 |

32 |

158.8 |

25 |

124.1 |

20 |

99.3 |

|

Grain storage: wheat needs to be unloaded from a truck and transported to a granary 20 meters away. A U-shaped screw conveyor is used, with a conveying capacity of 15 tons/hour and a 70% reduction in labor costs.

Feed production: soybean meal and corn meal are mixed and transported to a pelletizer. A double screw conveyor is installed, which increases the mixing uniformity by 40% and reduces energy consumption by 15%.

Chemical plant: calcium carbonate powder needs to be conveyed in a closed manner. A tubular screw conveyor is used, which meets the dust emission standards and extends the maintenance cycle by 3 times.

To ensure the normal operation of the spiral conveyor belt, the following are some maintenance recommendations:

Regular inspection: Regularly check key components such as the conveyor belt, spiral blades, and motors to ensure their normal operation.

Keep clean: Clean the residue on the surface of the conveyor belt in time after use to prevent blockage and affect the conveying efficiency.

Lubrication and maintenance: Properly lubricate moving parts to reduce wear and extend service life.

Monitoring operating status: Real-time monitoring of the operating status of the equipment to ensure its stable operation and timely resolution of possible problems.

Dahan Machinery focuses on the research, development, production and sales of various types of screw conveyors (U-type, tubular, flexible, etc.). The company has passed the ISO9001 quality management system certification, and its products comply with CE and GB/T standards and are widely used in grain, feed, chemical, building materials and other fields. We provide customized services and can adjust the pipe diameter, material (carbon steel/stainless steel), conveying angle and power configuration according to customer needs to meet different working conditions. The product covers 0.5-100 tons/hour conveying needs, provides free solution design + lifelong technical consultation, and 24-hour after-sales response to ensure worry-free use for customers.

With its unique structure, reliable working principle, significant performance advantages and wide application fields, the spiral conveyor belt has become an indispensable material conveying equipment in modern industrial production, providing more intelligent, high-speed and reliable material conveying solutions for various industries.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!