Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

It is used for the measurement and transportation of bulk solid materials. It is not easy to jam and return materials. It is made of stainless steel, easy to clean, and can prevent cross-contamination. The feeding height can be customized.

Price: $565.00 - $6,282.00/Set Chat Now

Diameter: 100mm-1250mm

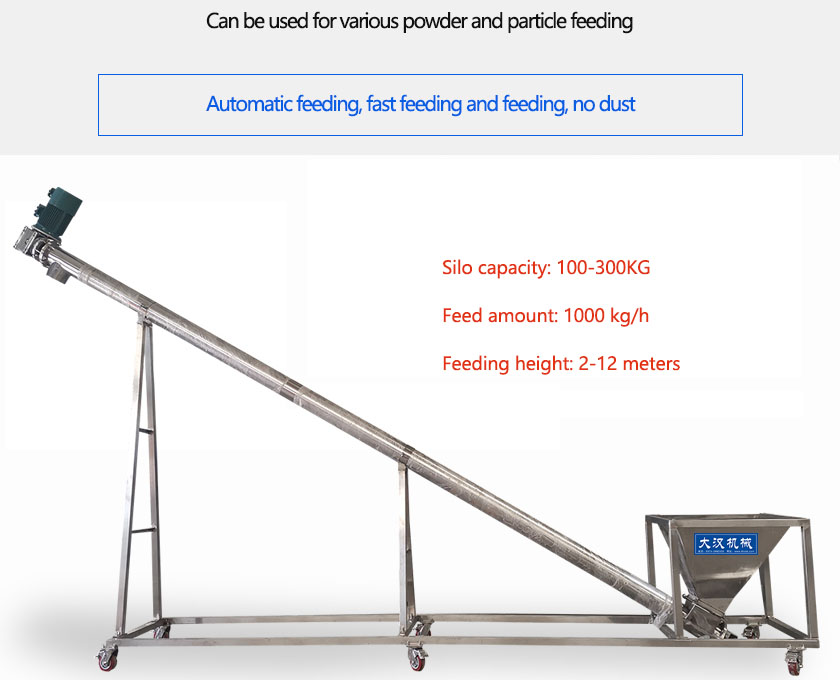

Silo capacity: 100-300KG

Feed amount: 1000 kg/h

Feeding height: 2-12 meters

Material: carbon steel, stainless steel, plastic

Arrangement form: horizontal, vertical, inclined

Application materials: flour, coffee powder, corn flour, concrete, cement, coal powder, ash, grain, etc.

Screw Feeder, also known as fully automatic screw feeder, unloads the material into the feeding bin of the screw feeder, and the motor rotates to drive the screw shaft to rotate, which drives the material to rotate, and uses the friction generated by the movement of the material and the shell wall to make the material flow smoothly. Convey clockwise to the outlet along the screw shaft. It is mainly used for conveying powder and granular materials, and is suitable for feeding equipment with certain high requirements in various industries. It adopts airtight conveying materials, which has good sealing performance, can avoid dust pollution to the environment, and can also eliminate the phenomenon of material backflow.

The Screw Feeder can be inclined or vertically loaded, and it can also be simply installed with a mobile shelf, which is more convenient to move. The feeding port of the feeding machine is designed with a hopper (can be used as a circle or a square), which is convenient for feeding. It can be used alone, and the pages can be directly connected with it. The supporting equipment is connected and fixed, no foundation is required, and the floor space is small.

Stainless Steel Screw Feeder - conveying flour

Vertical Screw Feeder-conveying feed

Screw Feeder is mainly used for feeding powder and granular materials below 200°C, and can be arranged horizontally, vertically or obliquely; it is suitable for feeding equipment with certain height requirements, and can be matched with various specifications of extruders, high-speed mixers, and plastic mixers use.

| type | Tubular Screw Feeder | Vertical Screw Feeder | Mobile Screw Feeder | U-shaped Screw Feeder |

| features | Made of seamless steel pipe, well sealed, no dust | Vertical feeding, feeding height ≤ 8 meters | Unrestricted by any occasion, you can move freely | Small range / small distance transportation |

| price | $450.00-$5800.00 | $400.00-6300.00 | $530.00-$6690.00 | $500.00-$6500.00 |

1. Carbon steel Screw Feeder

Carbon steel material feeder is a commonly used material, which is widely used. The cost of carbon steel material is low, the conveying capacity is large, the heat insulation effect is good, no cooling device is required, and the power consumption is low, but the anti-corrosion and anti-rust effect It will be a little bit worse, but the normal delivery of materials can also be achieved.

2. Stainless Steel Screw Feeder

Made of SUS304/316 stainless steel, it is mostly used in food, medicine and other industries or enterprises that have high requirements for hygienic environment. The stainless steel material is acid-resistant, corrosion-resistant, and wear-resistant. , no distortion and deformation, and it is easier to clean up after use. Compared with carbon steel, its lifespan will be longer. Price: $580.00-$6600.00.

3. Plastic Screw Feeder

That is, corrosion-resistant Screw Feeder, made of plastic material, can resist strong acid and strong alkali corrosion, and is mostly used in chemical and other industries with strong corrosiveness.

1. The diameter of the feeding pipe is small, the volume of the silo is 100-300KG, the conveying capacity per hour can reach 3000KG, and the feeding height can reach 12 meters.

2. The part in contact with the material is made of stainless steel, and all welding joints are polished to achieve smoothness without residue, clean and hygienic, and can avoid cross-contamination of materials.

3. The Screw Feeder uses the rotation of the eccentric block fixed on the motor shaft to vibrate the material box, and the material is easy to form flow and convection, so that it can achieve no jamming, no arching, and smooth discharge. It is suitable for poor fluidity materials.

4. The spiral can be reversed to discharge the material. There is a gate at the lower end of the material tube. When it is activated, the stored material at the bottom of the hopper tube can be taken out from the gate.

5. There is a material cleaning port at the bottom, which can effectively prevent debris from entering the machine and causing blockage. An anti-blocking valve is set on the discharge end cover. Cut off the power by the switch.

6. Sensors can be installed to effectively protect the motor from burning out. It has the function of stopping when the material is full. It only needs to set the time of material consumption, without the need for workers to look after it. It has functions such as material level control, overload protection, and automatic feeding.

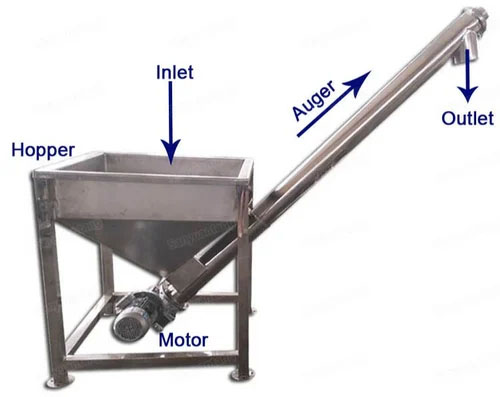

Screw Feeder is mainly composed of driving device, head section, middle section, tail section, head and tail bearings, feeding and discharging device and other parts.

Drive device: composed of motor and reducer;

Feed chute: It consists of head section, middle section and tail section. The chute is not equipped with a detachable cover plate, which can reduce dust flying and prevent the conveyed materials from being polluted;

Inlet and outfeed device: The screw feeder inlet is designed on the cover plate, the outlet is designed under the trough, and the inlet and outlet are designed with gate valve and unloader.

When the Screw Feeder is working, pour the raw materials into the material box of the screw feeder, turn on the switch, the motor drives the screw shaft to start rotating, and then the material rotates, and the friction between the material and the inner wall of the casing first, from the bottom of the material box by the screw The material is continuously lifted up to the discharge port. The system has a time setting, and the feeding time can be set according to the amount of each feeding.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Feeding capacity: 1000kg/h

Motor power: 1.5KW-6

Material box size: 900mm×700mm×950mm

Delivery pipe: stainless steel

Spiral blade: made of stainless steel (anti-corrosion material can be customized)

Spiral spindle: seamless stainless steel pipe

Storage box: made of stainless steel

Loading capacity: 250kg

1. When choosing a Screw Feeder, we should accurately measure the vertical feeding height, the lateral distance from the feed hopper to the discharge port, and the material to be fed, so that the machinery factory can draw up drawings and design the pitch of the blades inside.

2. The feeding speed of Screw Feeder is fast, and it can feed powder, crushed materials, raw materials, etc. or mixed materials. It makes up for the shortcomings of inconvenient powder suction and low output of the suction machine, but it also has some disadvantages, that is, it is not suitable for machines that often need to change colors, because the machine is sealed and welded, so it is not easy to clean. color.

3. Use sealed maintenance-free bearings, fill the bearing seat cavity with grease to prevent dust and impurities from entering the bearing seat, and ensure the normal operation of the machine.

4. In order to prevent metal debris from entering the tube body of the feeding machine, a screen should be added to the feeding port.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!