Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Stainless steel grain suction machine for fertilizers is a kind of agricultural machinery equipment specially used for sucking fertilizer particles. It is usually made of stainless steel, which has the characteristics of corrosion resistance, wear resistance and long service life.

The working principle of a stainless steel fertilizer suction machine generally involves the following steps:

Suction of fertilizer granules or powder: First, the fertilizer granules or powder are sucked into the conveying pipe or container of the suction machine. This is usually achieved through the airflow generated by a negative pressure system or a fan.

Transporting fertilizer: Once the fertilizer enters the suction machine system, the airflow transports the fertilizer granules or powder along the conveying pipe or container to the target location. This process can control the conveying path and speed of the fertilizer by adjusting the airflow speed and direction.

Filtering and separation: During the conveying process, filters or separators may be passed to remove any impurities or foreign matter to ensure that the conveyed fertilizer is clean.

Target location: Ultimately, the fertilizer granules or powder are transported to the desired target location, which can be a specific workstation on the production line, packaging equipment or other processing equipment.

Stainless steel fertilizer granulator has a wide range of applications in agriculture and fertilizer production, mainly used in the following scenarios:

Fertilizer production line: In the fertilizer production process, stainless steel fertilizer granulator is usually used to transport raw materials, additives or finished fertilizer granules from one workstation to another to achieve an automated production process.

Fertilizer packaging: In the fertilizer packaging process, the granulator can be used to transport fertilizer granules from the storage container to the packaging machine for packaging and encapsulation.

Fertilizer mixing: In the fertilizer mixing production line, the granulator can be used to transport fertilizer granules of different components into the mixer for uniform mixing.

Fertilizer distribution: In the agricultural field, the granulator can be used to transport fertilizer granules from warehouses or storage facilities to farmlands or planting areas for fertilization operations.

Fertilizer processing: In fertilizer processing plants, the granulator can be used to process and transport various types of fertilizer granules or powders to meet the needs of different customers.

Stainless steel fertilizer suction machine has many advantages over other materials, mainly including the following points:

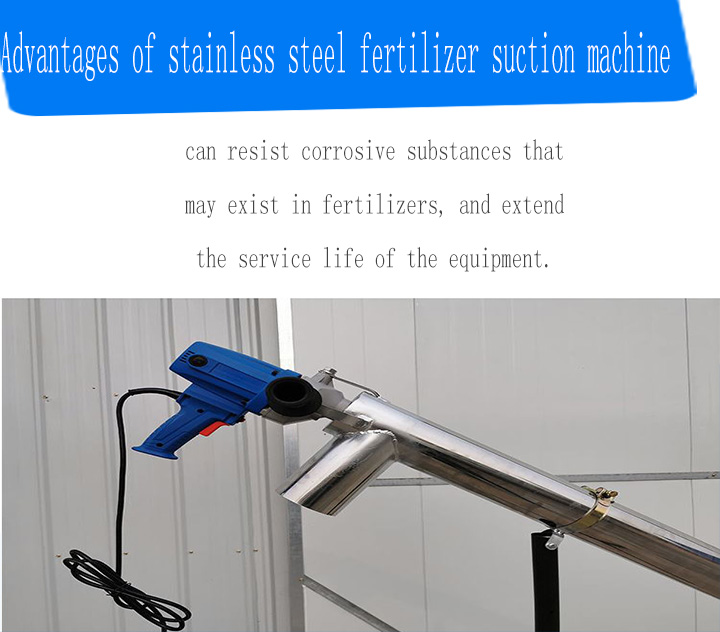

Strong corrosion resistance: Stainless steel has excellent corrosion resistance, can resist corrosive substances that may exist in fertilizers, and extend the service life of the equipment.

Improve fertilizer utilization: It can quickly absorb fertilizer particles scattered during fertilization, reduce fertilizer waste, and improve fertilizer utilization.

Easy to clean: The surface of stainless steel is smooth and not easy to adhere to dirt. It is easy to clean and maintain, which helps to ensure the hygiene and safety of fertilizers.

Meet hygiene standards: Stainless steel is a material that meets hygiene standards and is suitable for industries with high hygiene requirements, such as food processing and pharmaceutical industries.

High temperature resistance: Stainless steel has good high temperature resistance and is suitable for occasions that need to work in high temperature environments.

When choosing a stainless steel fertilizer suction machine, you can consider the following points as selection suggestions:

Production scale: Determine the required suction machine model and production capacity according to the production scale to ensure that the equipment can meet production needs.

Fertilizer properties: Consider the properties of the fertilizer being processed, such as particle size, density, viscosity, etc., and select a suitable suction machine model and configuration.

Working environment: Consider the working environment of the equipment, including factors such as temperature, humidity, and dust conditions, and choose corrosion-resistant and high-temperature resistant stainless steel materials.

Cleaning requirements: If the cleanliness requirements of the equipment are high, it is recommended to choose an easy-to-clean design, such as a smooth surface and a structure without dead ends.

Safety: Ensure that the equipment meets relevant safety standards, such as protective devices, emergency stop devices, etc., to ensure the safety of operators.

In short, the stainless steel grain suction machine for fertilizers is a convenient agricultural tool that can greatly improve fertilization efficiency, reduce fertilizer waste, and improve fertilization effects.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!