Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Trough screw conveyor can convey granular, powdery and small pieces of materials as well as some sticky and easy-to-entangle materials.

Conveying length: 10-20 meters

Delivery capacity: 9-134m³/h

Tilt angle: horizontal or tilted below 20 degrees

Customization: material (carbon steel or stainless steel), screw shaft (with/without shaft, single shaft/double shaft), import and export distance, feed port size, etc. (customized on demand)

Applications: Widely used in pet food, plastic processing, soap, washing powder and detergent processing, animal feed processing, wood processing, chemical industry, environmental technology, cement, lime and gypsum processing, and mining industries all over the world.

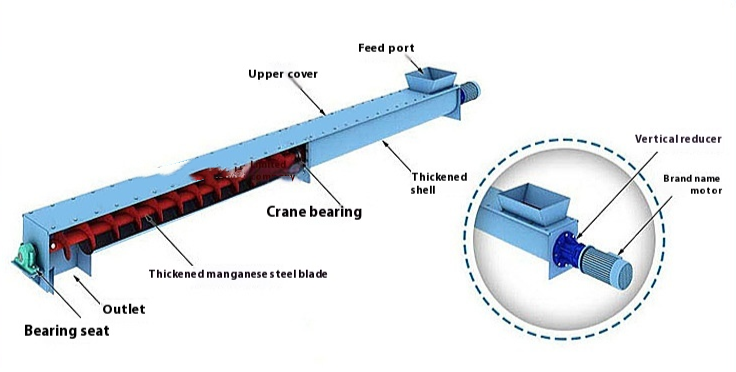

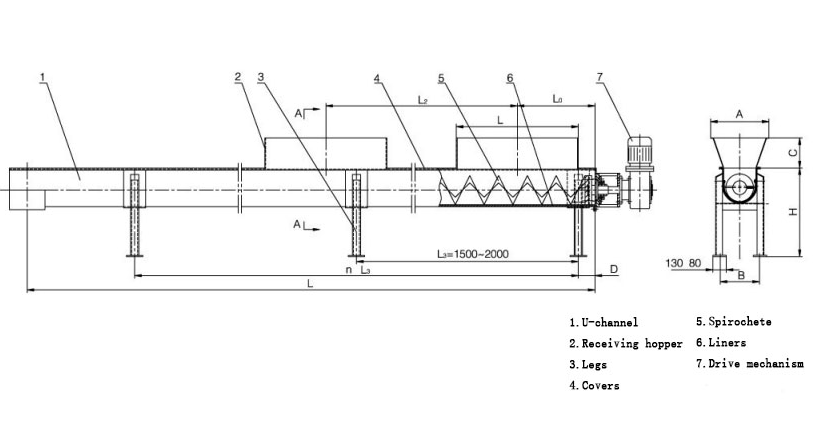

Trough Screw Conveyors use spiral blades to rotate in a closed U-shaped or O-shaped trough body, thereby pushing the material along the axial direction of the trough body for continuous conveying. Its upper cover can be opened at any time to check the material conveying situation, which is convenient for maintenance. It is usually designed with shaftless and shaft designs.

The main components of trough screw conveyors include.

Screw shaft: The screw shaft is the core component of the conveyor, usually made of seamless steel pipe, with spiral blades welded on the surface.

Spiral blades: The spiral blades are the key components for pushing materials. Depending on the conveying material, the blades can be divided into solid surface type, belt surface type and blade surface type.

Conveying trough: The conveying trough is the channel for materials, usually made of steel plate, with sufficient strength and wear resistance.

Drive device: The drive device includes a motor, a reducer and a coupling to provide power for the screw shaft.

Feed inlet and discharge port: The feed inlet is used to receive materials, and the discharge port is used to discharge materials.

The working principle of trough screw conveyor is relatively simple and intuitive. When the driving device drives the screw shaft to rotate, the spiral blades welded on the screw shaft also rotate. Due to the friction between the material and the trough body and between the material particles, the material pushed by the spiral blades will not rotate, but move forward along the axial direction of the trough body, and finally be discharged from the discharge port, thereby realizing the transportation of materials.

The reason why trough screw conveyor is widely used in many industries is due to its following significant features

Simple structure and low manufacturing cost: Compared with other types of conveyors, the structure of trough screw conveyor is relatively simple, with fewer parts, so the manufacturing cost is relatively low.

Easy maintenance and simple operation: Simple structure also means that maintenance is relatively easy, and daily inspection and lubrication can ensure the normal operation of the equipment.

Good sealing and good environmental performance: The closed trough structure can effectively prevent dust flying and material scattering during transportation, reducing environmental pollution.

Can achieve multi-point feeding and discharging: By setting multiple feeding ports and discharging ports on the trough body, it can meet the needs of multi-point feeding and unloading in the process flow.

Suitable for a variety of powdery, granular and small block materials: It can transport a variety of bulk materials such as cement, fly ash, grain, feed, chemical raw materials, etc.

Prevent material leakage: The trough design effectively avoids the leakage of materials during transportation and reduces the loss of materials.

|

Specification |

Main technical performance |

Drive device |

Drive device |

Weight(kg) |

|||

|

Diameter |

Length(m) |

Yield( t/h) |

Rotating speed(min) |

Reducer |

Electric motor |

||

|

Model |

Speed ratio |

Power(kw) |

|||||

|

U 200 |

-10 |

9 |

60 |

ZQ250 |

23.34 |

1.1 |

726 |

|

U 200 |

-20 |

9 |

60 |

ZQ250 |

23.34 |

1.5 |

1258 |

|

U 250 |

-10 |

15.6 |

60 |

ZQ250 |

23.34 |

2.2 |

960 |

|

U 250 |

-20 |

15.6 |

60 |

ZQ250 |

23.34 |

3 |

1750 |

|

U 300 |

-10 |

21.2 |

60 |

ZQ350 |

23.34 |

3 |

1373 |

|

U 300 |

-20 |

21.2 |

60 |

ZQ350 |

23.34 |

4 |

2346 |

|

U 400 |

-10 |

51 |

60 |

ZQ400 |

23.34 |

5.5 |

1911 |

|

U 400 |

-20 |

51 |

60 |

ZQ500 |

23.34 |

11 |

2049 |

|

U 500 |

-10 |

87.5 |

60 |

ZQ400 |

23.34 |

7.5 |

2381 |

|

U 500 |

-20 |

87.5 |

60 |

ZQ650 |

23.34 |

18.5 |

5389 |

|

U 600 |

-10 |

134.2 |

45 |

ZQ750 |

23.34 |

22 |

3880 |

|

U 600 |

-10 |

134.2 |

45 |

ZQ850 |

23.34 |

55 |

7090 |

Our factory sells two types of trough screw conveyors with shafts and shaftless, which can adapt to the transportation of different types of materials.

|

Comparison Items |

Shafted Screw Conveyor |

Unshafted Screw Conveyor |

|

Structural Features |

Screw blades are fixed on the shaft. The screw shaft is typically made of high - strength carbon steel or stainless steel, enabling it to bear large torques and axial forces. |

There is no central shaft, and the screw body is an integrated ribbon - shaped screw blade. This structure makes the unshafted screw conveyor less likely to be entangled by impurities in the materials during conveyance and capable of adapting to more complex material environments. |

|

Working Principle |

Depends on the rotation of the screw shaft to drive the rotation of the screw blades, causing the materials to move axially along the trough under the impetus of the blades. During conveyance, the materials are mainly affected by the thrust and friction of the screw blades. |

The motor drives the rotation of the screw body, and the rotation of the screw body pushes the materials to move in the trough. Due to the lack of a central shaft, the materials can flow more freely during conveyance, especially suitable for conveying viscous and entangled materials. |

|

Applicable Materials |

Suitable for various powdery, granular, and small - block materials, such as grains, fertilizers, cement, sand, stones, etc. |

Mainly used for conveying viscous, humid, entangled, and fibrous materials, such as sludge, garbage, kitchen waste, kelp, fruits, etc. |

|

Conveying Capacity |

Under the same specifications and rotational speeds, the conveying capacity of the shafted screw conveyor is generally greater than that of the unshafted screw conveyor. This is because the structure of the screw blades of the shafted screw conveyor is relatively stable and can withstand greater material pressure. |

Due to the structural characteristics of the screw body, its conveying capacity is relatively small. However, for some special materials, such as high - viscosity and high - humidity materials, the unshafted screw conveyor can achieve stable conveyance while ensuring the conveying effect. |

|

Application Scenarios |

Widely applied in industries such as grain processing, chemical industry, building materials, and metallurgy. |

Commonly used in industries such as environmental protection, sewage treatment, garbage treatment, and food processing. |

|

Maintenance |

During maintenance, attention should be focused on the wear of the screw shaft and the working conditions of components such as bearings and seals. Due to the relatively complex structure of the shafted screw conveyor, the screw shaft needs to be disassembled during cleaning and maintenance, and the operation is relatively cumbersome. |

Maintenance is relatively simple, mainly checking the wear of the screw blades and the tightness of the trough. Since there is no central shaft in the unshafted screw conveyor, it is more convenient to clean the materials and replace the screw blades, reducing maintenance time and costs. |

Trough screw conveyors have a wide range of applications and are more suitable for conveying different types of materials.

Powdered materials: For powdered materials such as flour, cement powder, coal powder, and fertilizer powder, trough screw conveyors can achieve stable and efficient transportation. By reasonably designing spiral blades and machine troughs, powdered materials can be prevented from dusting and leaking during transportation.

Granular materials: Granular materials such as grain particles, plastic particles, gravel, sand, etc. are common conveying objects of trough screw conveyors. It can select appropriate spiral parameters according to the particle size and conveying volume requirements.

Small block materials: Small block materials such as coal blocks, ore blocks, building debris, etc. can also be conveyed by trough screw conveyors after proper pretreatment.

Viscous materials: For materials with certain viscosity, such as sugar paste, sludge, and viscous intermediates of certain chemical raw materials, trough screw conveyors can effectively prevent materials from adhering to the blades and machine troughs by adopting special spiral blade structures and surface treatments, as well as appropriately reducing the conveying speed.

When selecting trough screw conveyors, the following factors need to be considered comprehensively

Characteristics of conveyed materials: Including material particle size, density, humidity, viscosity, abrasiveness, etc. Different material characteristics require the selection of screw conveyors with different materials, structures and speeds.

Conveying volume: That is, the amount of material that needs to be conveyed per unit time, which is an important parameter for determining the specifications of screw conveyors.

Conveying distance and inclination angle: Conveying distance and inclination angle will affect conveying efficiency and required power.

Process layout requirements: Including the location and quantity of feed and discharge ports.

Environmental requirements: Whether special requirements such as sealed conveying and explosion-proof are required.

Dahan Machinery has many years of industry experience. Our production base is equipped with advanced equipment and professional technical teams. It has strong production capacity and can efficiently meet the needs of orders of different sizes. Products cover a full range of shafted and shaftless trough screw conveyors. We attach importance to customized services, provide personalized solutions based on customer working conditions and material characteristics, and follow up from selection to installation and commissioning. In terms of service, we have built a complete system. The pre-sales professional team provides detailed consultation and technical support to assist customers in accurate selection; during sales, we strictly control the production progress and provide timely feedback; after sales, we have a quick response mechanism to provide regular maintenance, repairs and accessories supply to ensure long-term and stable operation of equipment.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!