Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

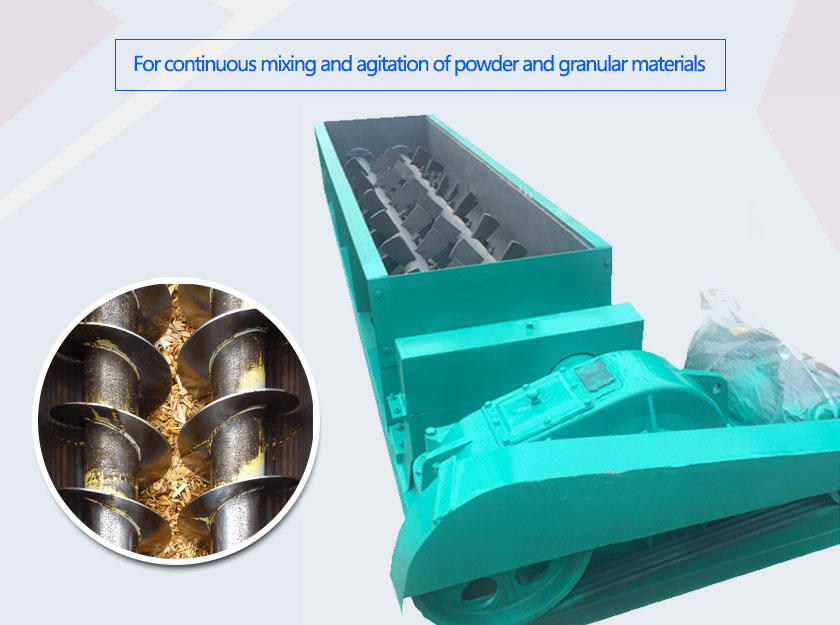

Double Screw Mixer uses two stirring shafts to continuously mix and stir powder or granular materials, and high-speed stirring for 60-90 seconds is enough.

Price: $800.00-$4,560.00/Set Chat Now

Output: 50-100 cubic/hour

Each processing volume range: output 1000-3000L

Materials: fly ash, dust, cement, lime powder, etc.

Double Screw Mixer adopts two symmetrical stirring shafts to rotate synchronously, add water and stir while conveying dry ash and other powdery materials, and evenly humidify the dry ash powdery materials, so that the wetted materials do not emit dry ash and do not produce seepage water droplets It is to facilitate the loading and transportation of humidified ash or transfer to other conveying equipment.

Double Screw Mixer Customer Case

Double Screw Mixer is a device that uses a pair of stirring shafts with stirring blades to rotate synchronously to spray, humidify and stir while conveying powdery materials. It can be used for stirring and crushing clay materials in the ceramsite industry, stirring and mixing fly ash, aggregate, additives and other raw materials evenly. This type of equipment has high stirring efficiency and compact structure. It is used for humidifying, stirring and transporting solid granular materials or powders in chemical, mining, ceramsite and other industries.

Dahan Twin Screw Mixer Manufacturer is committed to providing efficient and reliable mixing solutions for various industries. Our twin screw mixers are widely used in chemical, food processing, building materials and other fields, with excellent mixing effect and outstanding production efficiency. We can provide personalized design and solutions according to the specific needs of customers to ensure that different process requirements are met. The price is generally between $800.00-$4,560.00/Set. If you are looking for a high-quality twin screw mixer supplier, we welcome you to contact us!

1. When working, there are two blades with opposite rotation directions to stir. The stirring speed is fast and the uniformity is good. It can stir viscous materials with a water content of 30%.

2. The inlet of Double Screw Mixer is designed on the top, and there are two rows of humidifiers to spray water, which can ensure uniform water spray and humidity to meet the transportation requirements.

3. The entire stirring and conveying process is carried out in a closed space without dust leakage.

4. The mixing blades are made of wear-resistant materials and have high wear resistance after special surface treatment.

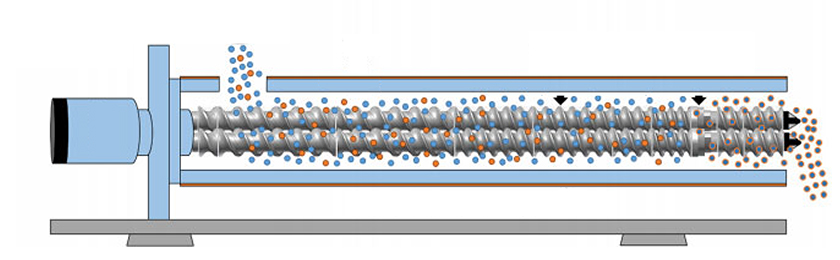

When the Double Screw Mixer is working, the material enters the mixing tank through the feed port. Driven by the vibrating motor, the two stirring shafts rotate in reverse. The material is driven by the rotation of the mixing blade and then moves in the same direction, so as to achieve the purpose of mixing and stirring while conveying.

| model | Output(mm³/h) | Equipped with power (kw) | Spindle speed(rev/min) | Dimensions Length × Width × Height (mm) |

| SJ360×40 | 30-40 | Y4-75 | 50 | 5750*2330*1040 |

| SJ360×36B | 25-35 | Y4-55 | 56 | 5600×2230×850 |

| SJ360×32B | 20-30 | Y4-45 | 52 | 5530×2220×800 |

| SJ280×32 | 20-30 | Y4-37 | 57 | 4560×1280×735 |

| SJ260×32 | 20-30 | Y4-30 | 57 | 4350×1280×735 |

| SJ240×28 | 15-20 | Y4-22 | 57 | 4100×1200×800 |

| SJ240×40 | 10-15 | Y4-18.5~22 | 58 | 3970×1200×800 |

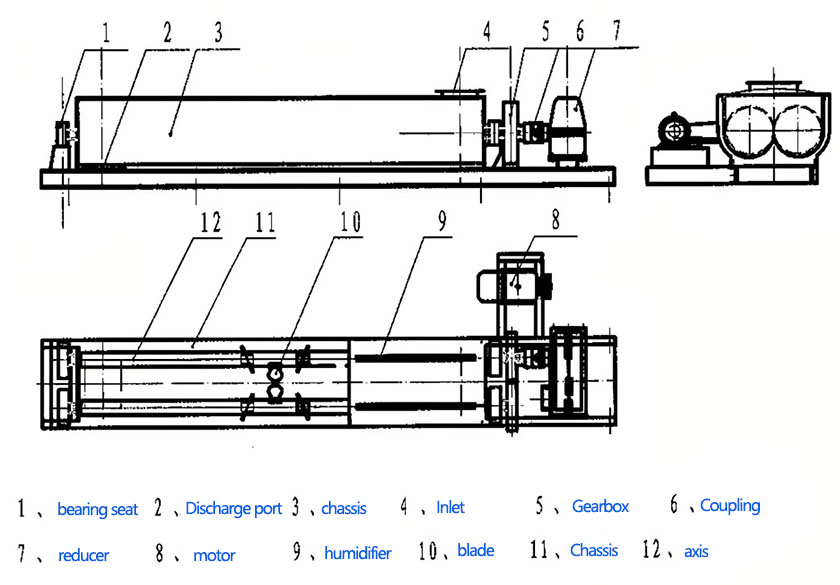

Double Screw Mixer is mainly composed of a driving device, a material inlet, a stirring shaft, a tank body, and a material outlet.

Double Screw Mixer is mainly composed of a driving device, a material inlet, a stirring shaft, a tank body, and a material outlet.

1. Driving device: The driving device is usually composed of an electric motor or other power source, which is used to drive the stirring shaft of the mixer to operate, so as to achieve the mixing and stirring of materials.

2. Feeding port: The feeding port refers to the position where the material enters the mixer, which is usually located on the side or top of the mixer, and is used to put the raw materials to be mixed.

3. Stirring shaft: The stirring shaft is a shaft connected to the driving device, which is usually equipped with spiral blades or stirrers, and the materials are mixed and stirred by rotation.

4. Tank body: The tank body is the main structure for holding the mixed materials, usually a closed cylindrical or rectangular tank body, which ensures that the materials will not overflow during the mixing process.

5. Discharging port: The discharging port is usually located at the bottom or side of the mixer, which is used to discharge the mixed materials and transport them to the next process or container.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!