Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Pipe Screw Conveyor conveys powdery or granular materials horizontally, obliquely and vertically in a closed pipeline with high speed, which can ensure smooth, fast and uniform conveying, and is not easy to jam. The sealed pipeline design prevents dust during conveying.

Price: $450.00-$18,000.00/Set Chat Now

Diameter: 100-1250mm

Length: 70 meters

Delivery capacity: 458 cubic meters / hour

Applicable materials: horizontal or inclined conveying powder, granules and small lump materials

Application fields: Flour processing industry (bran, flour, etc.), feed industry (pet feed, fish feed, etc.) and conveying of bridging materials (such as sawdust, soybeans, etc.).

Pipe Screw Conveyor is also called tubular screw conveyor. It is round in shape and made of seamless steel pipe. For bulky materials, there are three types of pipeline screw conveyors: LS, GX, and GL, with screw diameters of 150, 200, 250, 300, 400, 500, and 600mm in seven specifications; the shortest body is 3m, and the longest can reach 60m, with a step difference of 0.5m, carbon steel and stainless steel can be selected according to the conveyed materials and application scenarios.

Pipe Screw Conveyor can provide various standard solutions for the handling of powdery or granular materials, different types of conveyors can be used for grain (wheat bran, flour, corn, rice husk, wheat), chemical industry (fertilizer, plastic granules, laundry powder), coal production (coal powder, dedusting ash), concrete production (fly ash, filler dust, silica fume), premixed building materials (dry plaster, sand, cement, additives), glass processing (calcium carbonate, soda , sand) etc.), foundries (sand, bentonite) etc.

Pipe Screw Conveyor can be divided into three types: horizontal, inclined and vertical according to the conveying angle.

Horizontal Pipe Screw Conveyor: When materials are added to a fixed machine trough, due to the gravity of the material and the friction between the machine trough, the material accumulated in the lower part of the machine trough does not rotate with the spiral body, but is only driven by the rotating helical blade Moving forward, it is like the non-rotating nut doing translational movement along the rotating screw to achieve the purpose of conveying materials. It is suitable for continuous and uniform conveying of loose materials horizontally or slightly inclined (below 20º). It is mainly used for conveying materials horizontally or at small inclinations. The conveying distance is generally not more than 70 meters.

Inclined Pipe Screw Conveyor: The electric motor is used to drive the screw to rotate through the reducer. Through the rotation, the material is pushed along the fixed casing for conveying work, so as to be conveyed to the predetermined position. The conveying inclination angle is 0°-60°, and the length is generally different. more than 6 meters.

Vertical Pipe Screw Conveyor: The rotating speed of the screw body is higher than that of ordinary screw conveyors. Under the action of centrifugal force, the added materials generate friction with the casing, which prevents the materials from rotating with the screw blades and overcomes the gravity of the materials falling , so as to realize the vertical conveying of materials. Structurally speaking, it conveys materials vertically upward at 90° from the ground, which saves a lot of space and space compared with other screw conveyors. It is suitable for conveying powdery and granular materials with good fluidity. It is mainly used for lifting materials, and the lifting height is generally not greater than 8 meters.

1. The hourly conveying capacity can reach 142 cubic meters, and the conveying length of a single machine can reach 70 meters;

2. The suspension-type intermediate suspension bearing frame increases the space for material transportation, and the design of small diameter, high speed and variable pitch can ensure that materials can be fed more smoothly, quickly and evenly;

3. The inlet and outlet can adopt various forms such as flange connection, fabric connection, fabric hanger connection, universal interface connection, etc., with strong adaptability;

4. Fully enclosed conveying, no dust leakage, no need to install dust collector at the outlet;

5. Different angles can be designed according to the requirements of the conveying site ((gx<200°, ls<150°).

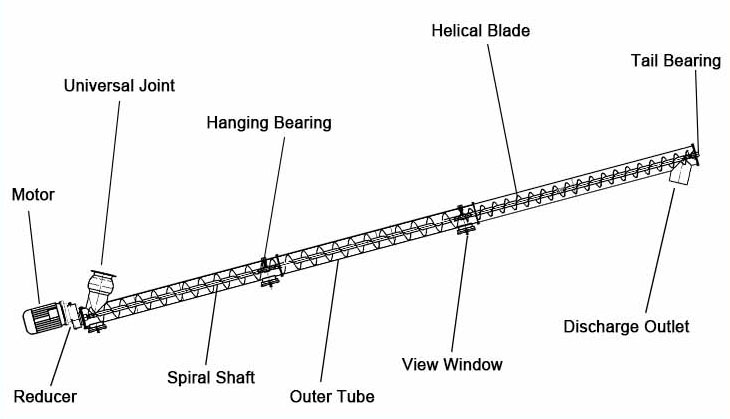

Pipe Screw Conveyor is composed of head bearing, tail bearing, suspension bearing, screw, casing, cover plate and base, and its driving device is composed of motor, reducer, coupling and base.

When the Pipe Screw Conveyor screw shaft rotates, due to the impetus of the blades and the gravity of the material itself, the material will rub against the inner wall of the material tube, and the internal friction force will cause the material to slide relative to the screw blade and the material tube. The template moves forward in the material pipe to complete the conveying of materials.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!