Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Made of polypropylene PP, it is specially designed for the transportation of manure and other corrosive materials in breeding plants; it is resistant to acid and alkali corrosion, wear resistance, and is not easy to deform.

Price: $500.00-$20,000.00/Set Chat Now

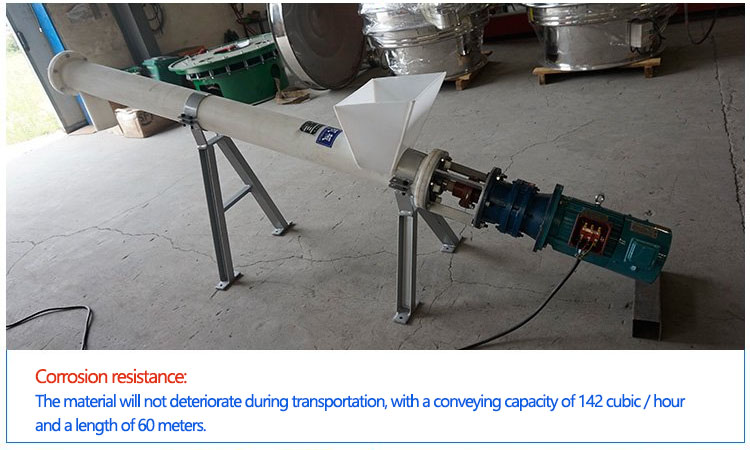

Delivery capacity: 142 cubic / hour

Conveying length: 60 meters

Application: removal of animal manure in chicken coops, duck coops, pig farms, cattle farms, sheep farms, etc.

Selection Type: Horizontal, Slanted, Vertical

Select the shape: tube, u-shaped

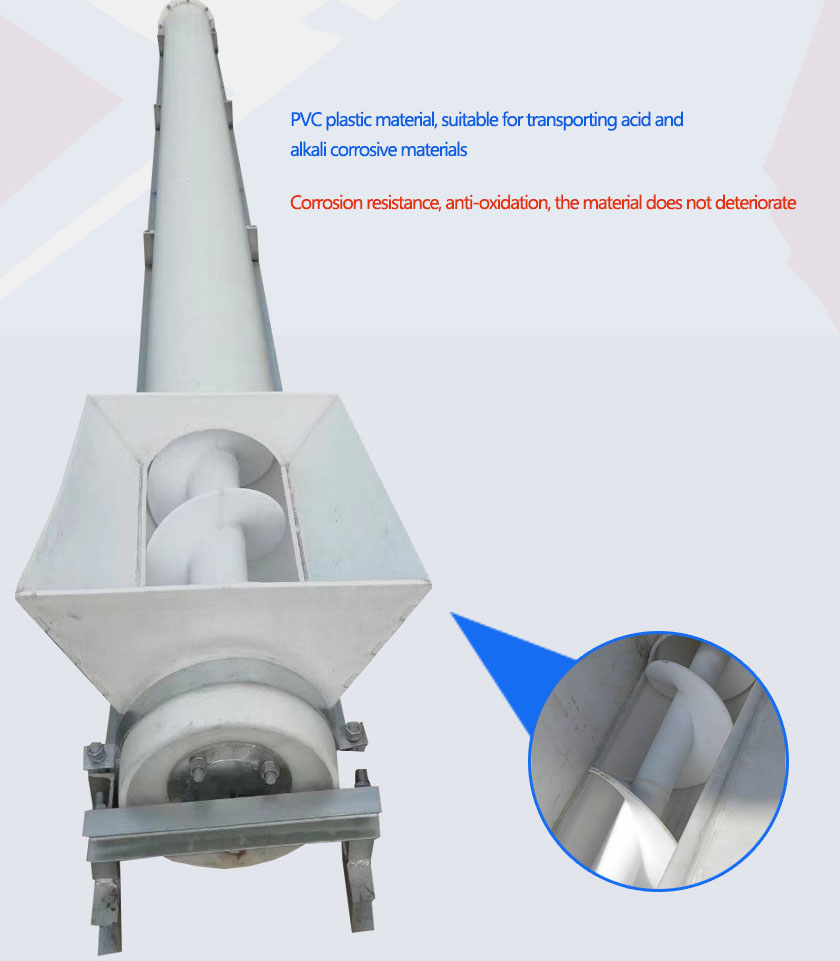

The spiral tube and blades of the Plastic Screw Conveyor are made of PVC plastic material. Compared with the metal auger, it has better corrosion resistance, can effectively avoid reaction with corrosive materials, and has a longer service life. It is mainly used in chicken coops, duck coops, cattle farms, pig farms, etc. that need to remove animal manure. The manure removal speed is fast, time-saving and labor-saving, well sealed, and the manure is clean. Users can lift the manure out of the shed without leaving the shed. Or on a dung cart.

Plastic Screw Conveyor can be used to clean manure in large/small chicken farms, pig farms, duck tongues, cattle farms, pig farms and other farming industries. The manure can be conveyed to the plastic manure cleaning auger through the manure cleaning conveyor belt, and then the manure is cleaned The auger is transported to the outside of the chicken shed, and the whole process does not require manual cleaning, and the operation is simple.

In addition, plastic screw conveyors are also suitable for the following industries:

1. Food processing industry: used to convey food raw materials, granular food, powder, etc.

Chemical industry: used to convey chemical raw materials, granular chemical products, plastic granules, etc.

Pharmaceutical industry: used to convey pharmaceutical raw materials, granular pharmaceuticals, powder, etc.

Plastic processing industry: used to convey plastic granules, waste recycling, etc.

Agricultural field: used to convey grains, feed, seeds, etc.

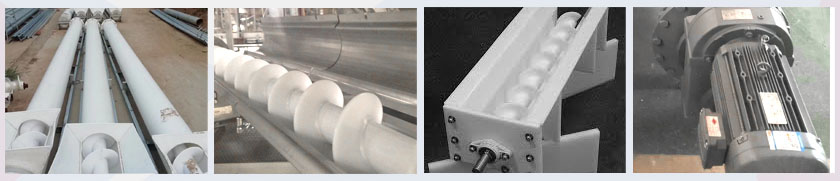

1. It is made of polypropylene plastic pp material, which is resistant to acid and alkali corrosion, wear resistance, and long service life.

2. The whole machine is small in size and light in weight, which is convenient for intermediate loading and unloading. It has high speed, fast and clean excrement removal, and the user can lift the manure out of the shed or pull the manure truck without going out of the shed.

3. The sealing performance is good, which can prevent the smell from overflowing and the feces from splashing out during the transportation process, so as to ensure the cleanliness of the farm space.

4. The conveying capacity can reach 142 cubic meters per hour, and the conveying length of a single machine can reach 60 meters.

5. Simple operation, time-saving and labor-saving, cheap price and low input cost.

Plastic Screw Conveyor is mainly composed of plastic spiral tube, head bearing, tail bearing, suspension bearing, plastic screw blade, casing, cover plate, base inlet and outlet and driving device.

Note: The driving device should be placed on the outlet end as much as possible so that the screw shaft is under tension.

Spiral blade: The spiral blade is the core component of the plastic screw conveyor, responsible for pushing the material along the axis of the conveyor.

Pipeline: The conveying pipeline is the outer shell of the plastic screw conveyor, which is used to accommodate and wrap the spiral blade to ensure that the material does not scatter or overflow during the conveying process.

Feed inlet: The feed inlet is the location where the material enters the conveyor, and the discharge port is the location where the material is discharged from the conveyor.

Drive device: The drive device is responsible for driving the spiral blade to rotate and push the material for conveying. Usually includes components such as motors and reducers.

Support structure: The support structure is used to support and fix the various components of the plastic screw conveyor to ensure the stable operation of the conveyor.

Drive the rotation of the driving drum through the motor reducer, and then the driving drum drives the conveyor belt to move, transporting the chicken manure on the conveyor belt to the plastic manure cleaning auger, the plastic auger rotates to drive the chicken manure forward, and then transports it through the plastic screw conveyor To the septic tank outside the shed or on the transport vehicle.

Plastic Screw Conveyor produced by Dahan Mechanical Conveying Equipment Co., Ltd. is available in various models. If you have special needs, we can design it free of charge according to your actual situation.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

1. Different materials: ordinary screw conveyors are mostly made of carbon steel and stainless steel, but in order to meet the conveying requirements of corrosive industries, Plastic Screw Conveyor is made of anti-corrosion polypropylene (PP) material, which can ensure that the equipment will not be corroded .

2. Different application industries: There are no clear restrictions on the application industries of ordinary screw conveyors. It can be used in pharmaceutical, food industries, metallurgical, chemical and other industries that have strict hygiene requirements. The Plastic Screw Conveyor is not universal due to its high cost. It is only seen in the field of chemical preparations that cannot be in contact with metals, such as animal manure. Part of the field of chemical raw materials.

3. Different durability: Although plastic and alloy steel have good corrosion resistance, their strength and wear resistance are far inferior to steel. Therefore, compared with stainless steel vibrating screens, the durability of Plastic Screw Conveyor will be lower. The wear resistance is lower than that of the former, which determines that the overall service life of the Plastic Screw Conveyor is lower than that of the screw conveyor made of ordinary materials.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!