Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

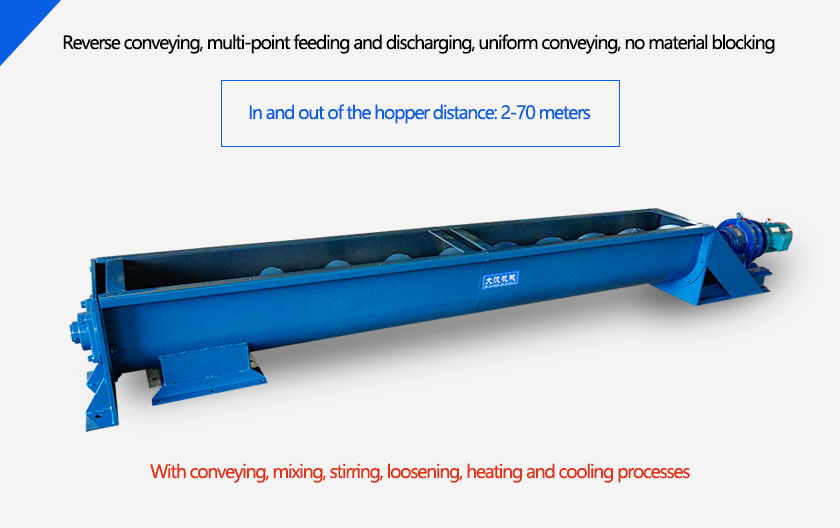

Auger Screw Conveyor can convey granular or powdery materials horizontally, obliquely and vertically. It adopts 6-8mm thick auger blades. It can load and unload at both ends/middle, and can also convey materials in two directions at the same time. The layout is flexible. It can complete the conveying and mixing, mixing, loosening, heating and cooling of materials simultaneously.

Price: $560.00-$2,500.00/Set Chat Now

Diameter: 100mm-250mm

Delivery capacity: 2.2-381 cubic/hour

Conveying height: 40-70 meters

Power: 0.75-30KW

Materials: grain, rice, corn, starch, feed, fly ash, cement, slaked lime, garbage, plastic, etc.

Auger Screw Conveyor, also known as auger screw conveyor, is a mechanical device that uses rotating spiral blades to push materials for transportation. The thrust generated by the rotation makes the materials move axially, and can achieve horizontal, inclined, vertical and other forms of transportation. This equipment is suitable for granular or powdery materials, such as grain, chemical raw materials, cement, etc. Its conveying distance varies depending on the model, and the length is usually about 2-30 meters. With its simple structure, easy operation, good sealing and other characteristics, the screw conveyor is widely used in agriculture, chemical industry, building materials and other industries.

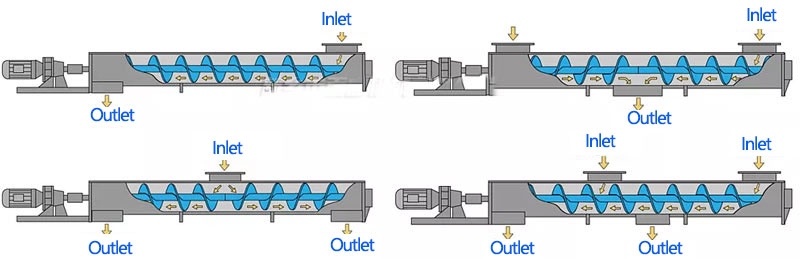

Auger Screw Conveyor can be divided into two types: shaft and shaftless. According to different materials, two different designs can be selected, loading and unloading at both ends, or middle loading and unloading, and the conveying direction can be reversed or simultaneously. Convey materials in two directions, flexible layout, can complete the process of material conveying and mixing, stirring, loosening, heating and cooling simultaneously.

Screw conveyors can be divided into many types according to different standards. Choosing the right type of screw conveyor can effectively improve the conveying efficiency and meet the needs of different industrial production.

Flexible screw conveyor: Flexible screw conveyor is suitable for equipment that conveys powdered or granular materials in a limited space, and is suitable for occasions that require curved conveying, height adjustment or conveying at different angles.

Stainless steel screw conveyor: Stainless steel screw conveyor is a conveying equipment made of stainless steel, mainly used in food processing, medicine, chemical industry and other fields to convey materials with high hygiene requirements.

Vertical screw conveyor: Vertical screw conveyor is used for equipment that conveys materials in the vertical direction, which can effectively convey materials from the bottom to the top.

Mobile screw conveyor: Mobile screw conveyor is used for equipment that needs to be moved and conveyed. It is usually equipped with mobile devices such as wheels or tracks, which can easily move and convey materials between factories, warehouses or other places.

Sludge screw conveyor: It is suitable for conveying viscous, winding, blocky materials, such as sludge, domestic garbage, electroslag, etc. It is generally arranged horizontally or inclined, but the inclination angle is generally not more than 20°, which is 1.5 times the axis.

Shaft Auger Screw Conveyor - Pulverized Coal

Shaftless Auger Screw Conveyor - Sludge

Auger Screw Conveyor is mainly used in sewage treatment plants, garbage recycling plants, sand yards, washed sand production lines, coal-fired boilers, etc. to transport powdery, granular, and small lump materials, such as cement, fly ash, and sludge. , Garbage, sludge, fertilizer, mineral powder, sand, soda ash, etc.

Sewage treatment plants: commonly used to transport sludge, solid waste or treated sewage residue.

Garbage recycling plants: can be used in garbage sorting and recycling processes to transport garbage, waste and other materials.

Sand fields and water-washed sand production lines: usually used to transport granular materials such as sand and aggregates.

Coal-fired boilers: commonly used to transport fuels such as fly ash, etc.

Screw conveyor is characterized by its simple structure, low cost and easy maintenance, but its stable performance and flexible layout make it an ideal choice for short-distance material transportation.

1. Large carrying capacity, safe and reliable, with a conveying capacity of 381 cubic meters per hour.

2. The whole machine is small in size and high in speed, ensuring fast and uniform conveying. The conveying length of a single machine is 60

3. Blade thickness 6~8mm, spiral blade material: carbon steel/stainless steel/manganese steel, strong adaptability, convenient installation and maintenance, and long service life.

4. Good sealing, the shell is made of seamless steel pipe, and the ends are connected with each other by flanges, with good rigidity.

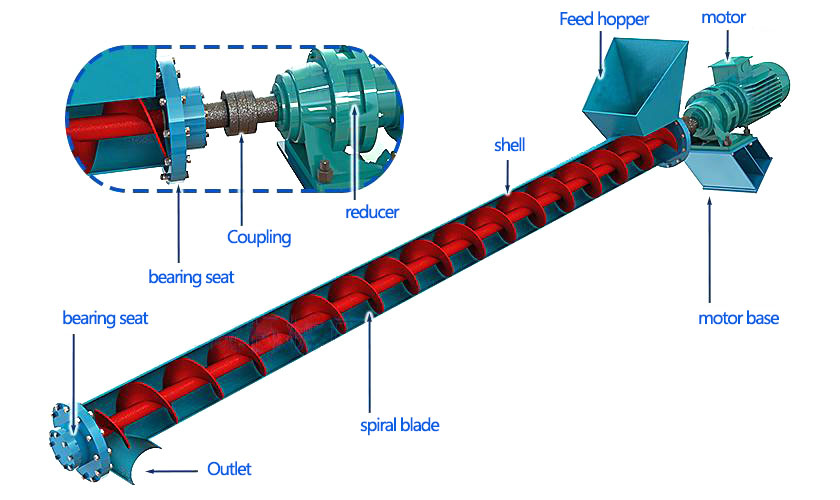

Auger Screw Conveyor is mainly composed of driving device, intermediate bearing, screw shaft, screw machine body, screw blade, head section, middle section, tail section, feeding and discharging device and other components.

Driving device: It is composed of a motor and a reducer. The driving motor is suitable for 380V, 3-phase, 50Hz. Its protection level is IP55 (outdoor type), and its insulation level is F class. Composed of gear reducer, high torque, low noise, no oil leakage.

Intermediate hanging bearing: divided into two types:

①Head bearing: Thrust bearing: bear the axial force generated by the resistance of conveying materials, and place it in front of the materials.

②Intermediate bearing: split sliding bearing, used to support the screw shaft.

Spiral shaft: hollow design, made of steel pipe, high strength, light weight, easy to connect. Use a short length of solid shaft at the shaft-to-shaft connection and where you mount the bearings. Available in carbon steel or stainless steel.

Spiral blade: divided into three forms: solid helicoid, belt helicoid and blade helicoid.

Inlet and outlet: There are two shapes, square and round, but this can also be selected by the user.

When the Auger Screw Conveyor works, it uses the vibration motor as the power source, and then relies on the rotating screw to push the material forward along the casing until it is discharged from the outlet.

| Specifications | Spiral diameter(mm) | Pitch (mm) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | |

| small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

| Material lumpiness | Material grindability | Filling factor | K | A |

| powdery | Unpolished, semi-polished | 0.35-0.40 | 0.0415 | 75 |

| powdery | Abrasiveness | 0.25-0.30 | 0.0565 | 35 |

| Small block a<60mm | Unpolished, semi-polished | 0.25-0.30 | 0.0537 | 45 |

| Small block a<60mm | Abrasiveness | 0.20-0.25 | 0.0645 | 25 |

In the industrial field, screw conveyors are usually made of wear-resistant and durable carbon steel, but can also be made of stainless steel, white steel or specially treated materials. Its main features include large conveying capacity and long conveying distance, and are suitable for handling industrial granular or powdered materials such as fly ash, small-grained stones and forging agents. These conveyors are designed to take into account the needs of high temperature resistance and corrosion resistance to ensure their stable operation in harsh industrial environments.

Industrial screw conveyors can be used in conjunction with micro screws, incinerators, elevators, crushers and other equipment to meet the conveying and processing needs of different industrial production processes.

Dahan Machinery Co., Ltd. is a company specializing in screw conveying machinery and equipment. It produces a variety of screw conveyors that can meet the needs of conveying granular and powdered materials at different distances from 2 to 30 meters. There are different types of conveying equipment such as stainless steel, carbon steel, hoses, and handheld. With advanced equipment to ensure quality, the products are sold well throughout the country and are widely used in the fields of electricity, building materials, chemicals, etc., and are highly recognized by users.

Spiral diameter: 150-1250mm

Material temperature: ≤80°C, such as high-temperature materials need to be explained in advance.

Conveying angle: the inclination angle of the screw conveyor with shaft auger is ≤45°, and the inclination angle of the screw conveyor without shaft auger is ≤30°

Speed: 60, 45r/min, the larger the diameter of the screw, the lower the speed.

Conveying length: 2-70 meters.

Conveying capacity: 1-100 tons/hour (cement), the larger the diameter of the screw, the greater the conveying capacity.

Equipment material: Q235, SUS304, SUS316L, etc.

Inlet and outlet: generally arranged at each end of the equipment, customized according to user needs.

(1) End feed, end discharge;

(2) The material is fed in the middle, and the material is discharged at both ends at the same time or alternately at both ends;

(3) Feeding at both ends and discharging in the middle;

(4) Feed in at the end or in the middle, and discharge in the axial direction at the other end or both ends.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!