Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Auger Screw Conveyor, referred to as auger conveyor, is an industrial conveying equipment used to convey a large amount of granular solids (such as powder, grain, granules), semi-solid, liquid and even non-flowing materials from one point to another. It can be used horizontally and vertically. And inclined conveying materials. So what are the models and parameters of Auger Screw Conveyor?

| Specifications | Spiral diameter(mm) | Pitch (mm) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | |

| small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

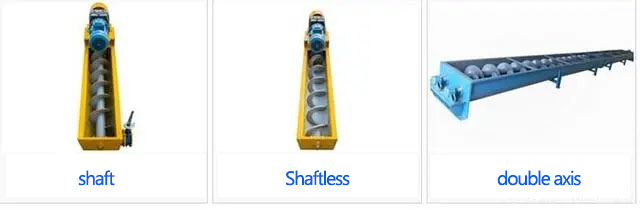

1. Auger Screw Conveyor with shaft: With a central shaft, it is suitable for conveying materials that are not easy to stick and have certain friction. The wear resistance of the screw conveyor has certain requirements. (Model parameters are consistent with conventional models)

2. Shaftless Auger Screw Conveyor: In a shaftless auger conveyor, the shaft of the conveying screw and its internal bearings do not exist. This eliminates material buildup and flow blockage issues. Therefore, the shaftless screw conveyor is suitable for conveying viscous, high water content and poor fluidity materials, such as sludge, garbage, etc. They simplify the handling of these materials and generally increase the efficiency of delivery. They are also used to convey products from mixers, centrifuges and filters.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

3. Two-axis Auger Screw Conveyor: Two seamless steel pipes are respectively equipped with solid screws, and the screw shafts on both sides turn to different directions, which can avoid the phenomenon of material blocking caused by material accumulation, and have the functions of conveying, mixing and stirring at the same time. The amount is 1.5-2 times that of the single axis.

| Specification | Main technical performance | drive unit | drive unit | Weight (kg) | |||

| diameter | length (m) | Output (cement) t/h | speed(min) | reducer | electric motor | ||

| model | speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

1. Horizontal Auger Screw Conveyor: Horizontally arranged, used to transport bulk materials from one part of a process to another process, by using multiple entry and discharge points, bulk materials can be efficiently distributed to the auger conveyor various locations. (Model parameters are consistent with conventional models)

2. Tilting Auger Screw Conveyor: The tilting angle ranges from 0 to 45 degrees above the horizontal line. As the inclination angle increases, the efficiency and load capacity of the auger conveyor decreases, while the power requirement increases due to the gravitational pull and fall back of the bulk material. The negative effect of inclination is compensated by using a conveying screw of reduced pitch (for example, one-half or two-thirds of the screw diameter), as it provides a better conveying surface and reduces material fallback, the use of tubular troughs Also reduces material fallback. (Model parameters are consistent with conventional models)

3. Vertical Auger Screw Conveyor: Vertical Auger Screw Conveyor transports bulk materials on vertical paths and very steep slopes with an inclination angle of 45 degrees above the horizontal. They are also space and cost efficient for transporting bulk materials. Controlling the amount of bulk material fed into a screw conveyor is critical to maintaining a constant speed on a vertical screw conveyor, reducing wear and power consumption, and increasing conveyor efficiency. Therefore, a large number of metering devices, such as screw feeders, are required.

The above is the specific description of the model and parameters of Auger Screw Conveyor!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!