Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

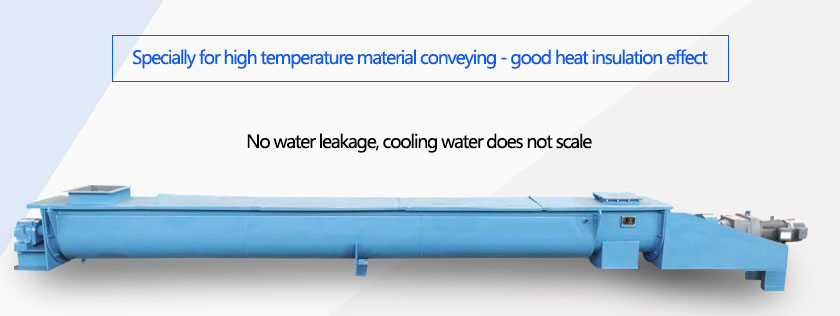

Cooling Screw Conveyor is a conveyor with cooling jacket that integrates conveying and cooling. It can cool the feed temperature up to 720°C to 50°C for discharge.

Price: $550.00 - $35,000.00 Chat Now

Spiral diameter: 300mm, 400mm, 500mm

Material temperature: feed: 720°C, discharge: below 100°C

Water temperature: Input: 40℃, Output: 55℃

Cooling water volume flow/capacity: 71.3m³/h

Capacity: 3-10m³/h

Conveying length: 7 meters

Materials: cement clinker, fly ash produced by cooling coal-fired power plant boilers, lime in heating asphalt shingle operations, keeping food at a specific temperature, cooling rotary dryer drill cuttings and other powdery, organic chemical raw materials

Cooling Screw Conveyor, also called Jacketed Screw Conveyor, is a cooling unit added to the ordinary screw conveyor, which can be used to transport high-temperature materials in metallurgical, chemical and other industries. It is used to transport high-temperature powder and small particles in a closed tube. For bulk materials, the maximum temperature of the feed can reach 720°C, and the cooling water flowing through the spacer and the central spiral tube makes the discharge temperature reach 50°C. It is a conveying equipment that integrates cooling and conveying.

The function of the cooling screw conveyor is to move hot materials or processed products along the conveying direction, and at the same time cool the materials through external cooling media, thereby effectively reducing the temperature of the materials. It can effectively control the temperature of the materials, protect the equipment, and ensure product quality.

In addition to transporting materials, the Cooling Screw Conveyor can also cool high-temperature materials. The cooling system is installed inside and outside the machine, and the outer cylinder of circulating water is used to keep the water at a low temperature and reduce the heat of the machine.

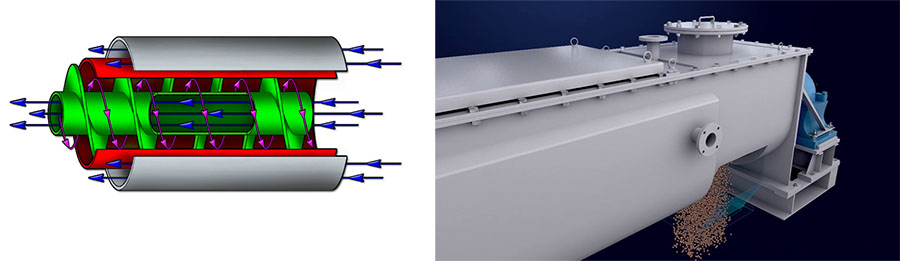

1. Cooling method: circulating water cooling.

2. Cooling system: internal cooling (rotating shaft), external cooling (jacket),

3. The direction of circulating cooling water: it enters from the outlet end of the semi-coke screw and flows out from the inlet end of the semi-coke screw.

4. Material: The part in contact with the material is 304 stainless steel (shaft diameter 159mm, blade thickness 10mm, spiral sleeve diameter 377mm, thickness 8mm), outer jacket material: Q235, pipe diameter 460mm, wall thickness 10mm.

5. The screw shaft and blade must be straightened and heat treated.

6. The length of the spiral casing cannot be greater than: 7000mm.

7. Atomizing nozzle (material 304): At the outlet end of the conveying screw, the upper part of the spiral blade is installed, and one is installed at an interval of 200mm at the inlet end of the conveying screw, and a total of three atomizing nozzles are installed, which can control the water volume independently or independently Easy disassembly for easy nozzle cleaning.

8. Screw shaft drive mode: connected shaft drive, equipped with frequency conversion speed regulation motor (motor power must be specified).

9. Requirements: The conveying volume is greater than 6m³ per hour, the temperature of the conveyed material is 450°C when it enters the screw inlet, and the temperature must be lowered to within 100°C when it is discharged.

Analysis of cooling methods

1. Circulating water cooling method: cooling water enters from the screw outlet and flows out from the screw inlet.

Circulating water cooling: The conveying pipe groove of the water-cooled screw conveyor is designed as a sandwich layer, equipped with a jacket of a certain length, and the jacket is equipped with cooling circulating water. After the material enters the conveying pipe groove, it rotates and continuously contacts with the cold water jacket to achieve the purpose of cooling.

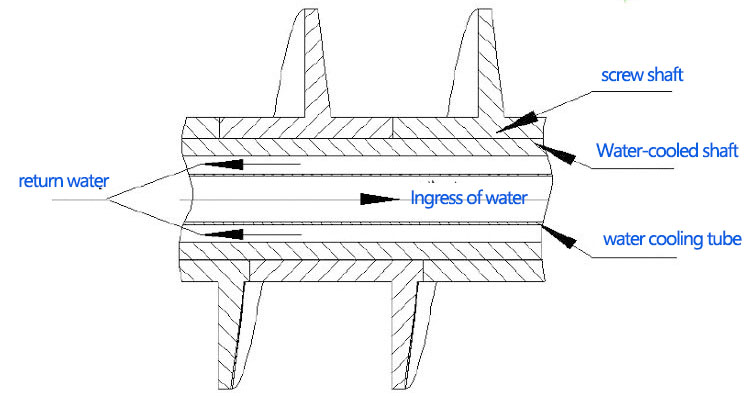

2. Cooling method: internal cooling (spiral), external cooling (jacket), internal and external dual cooling: internal cooling refers to the screw shaft, hollow design, can be filled with cold water, external cooling refers to the jacket, which can cover a large area of materials, Maximum cooling.

3. The length of the conveying pipe groove is the key to cooling down: the materials conveyed by the water-cooled screw conveyor are generally freshly burned materials or materials with high temperature, so it takes a certain amount of time to drop to the expected temperature during the conveying process. The longer the trough length, the better the cooling effect.

Cooling Screw Conveyor uses industrial water with low chlorite content as the cooling medium, which can meet the feeding and discharging requirements of regenerated sand in foundries, coal-fired power plants or drying plants, and is generally applicable to bed ash, Flue dust, sewage slurry, cyanide or pasture.

Common applications: cooling fly ash from coal fired power plant boilers, heating lime in asphalt shingle operations, maintaining a specific temperature for food products, cooling drill cuttings in rotary dryers, etc. The following are some common high temperature material applications:

1. Cool the ashes from 850°C to 150°C

2. Cool the active coal particles from 700°C to 40°C

3. Cool the salt from 110°C to 50°C

4. Cool the sludge granules from 120°C to 32°C

5. Cool the cement raw meal from 900°C to 150°C

6. Cool the metal oxide from 500°C to 50°C

7. Cool the pyrolysis residue from 560°C to 60°C

8. Cool the plastic from 120°C to 40°C

1. The cooling of the material is completed by water passing through the spiral jacket, which can reduce the temperature of the material from 720°C to below 50°C.

2. The installation height of the equipment is 3300mm, the length is 3000mm, and the width is 1100mm. The water pressure is 5kg, the water flow rate is 5T per hour, and the inlet water temperature is 40 degrees.

3. The conveying distance can reach 20 meters, and the soft connection of multiple machines can be extended arbitrarily according to the needs.

4. During the conveying process, the cooling effect of the material is better than that of natural cooling. In addition, our company's special design can prevent the cooling water from scaling in the spiral internal circulation, avoiding the problem of the net content of cooling water decreasing after long-term use.

Cooling Screw Conveyor consists of screw shaft, motor, reducer, water-cooled shaft, water-cooled tube and rotary joint.

Screw shaft: It is made of high temperature resistant and wear-resistant material, which can be replaced separately. The split screw blade is easy to disassemble and assemble, and the material flow is smoother, avoiding partial stacking.

Water-cooled shaft: It adopts a hollow structure and is made of high-quality steel, which serves as the bearing shaft of the screw shaft and transmits torque.

Water-cooled pipe: used for circulating cooling of the water-cooled shaft.

Working system: S1 (continuous working system)

Pressure: 0.6MP (working pressure of cooling water);

Cooling temperature: feed temperature 450 degrees Celsius, discharge temperature below 50 degrees Celsius

Cooling water velocity: 0.37m/s

Cooling water volume: 4.285t/h (the cooling water temperature is 20 degrees Celsius before cooling, and the amount of water required for 100 degrees Celsius after cooling).

Cooling Screw Conveyor adopts the principle of hollow spiral and heat exchanger. The hollow design provides a space and path for the cooling medium to flow through. At the same time, during the conveying process, the spiral blade and the screw shaft continuously rotate and continuously contact with the material being conveyed. Hollow The helical surface acts as a solid partition wall to separate the cooling medium from the material being transported to form heat exchange, thereby reducing the high temperature material from 750°C to 50°C. The design of the hollow jacket can not only cool the conveyed material, but also heat-insulate or heat-treat the material as required.

| Spiral diameter (mm) | 300 | 400 | 500 |

| Pitch (mm) | 300 | 400 | 500 |

| Speed(r/min) | 6 | 7 | 8 |

| Delivery capacity (m3/h) | 3 | 5 | 10 |

| Motor power (Kw) | 3 | 3-4 | 4 |

| Conveying distance (m) | <7 | <7 | <7 |

| Material temperature (℃) | <800 | <800 | <800 |

| Material specific gravity (%) | ≈0.8 | ≈0.8 | ≈0.8 |

| blade material | SU304 | SU304 | SU304 |

| Water pressure (MPa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| import and export | DN40 | DN40-50 | DN40-50 |

The Cooling Screw Conveyor transports high-temperature materials above 750°C. No matter what kind of material it is, it must use special steel, special support structure and bearings, special feeding port, variable speed electronic drive transmission, etc. All major components and accessories must be able to withstand high temperatures above 750°C.

(1) Material cooling range: The temperature difference between the highest temperature and the lowest temperature is used to design the cooling series, and the cooling length of a single machine does not exceed 7 meters.

(2) Cold source temperature: The initial temperature of the cold source temperature of 5°C and 30°C has different effects on the design of the same equipment. It is necessary to prepare the necessary information before the design plan to facilitate the design of a reasonable water cooling plan.

(3) Material properties: Different materials have different heat dissipation properties; before ordering equipment, accurate material properties must be provided so that our factory can perform calculus simulation to ensure the cooling effect.

(4) Equipment installation space location: It is beneficial to the application of low-temperature cooling, and a larger area is required for occasions with a large cooling range. The arrangement can be arranged horizontally, vertically, or diagonally. to meet location requirements.

(5) On-site power supply: In the design of water-cooled cooling, the ultra-high temperature cooling system is not limited to the form and structure of water-cooled cooling. The design plan will also design composite process structures such as air cooling and air cooling.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!