Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Grain Auger Conveyor is a kind of equipment specially used for conveying grain, usually made of stainless steel.

Diameter: 100mm-1250mm

Length: 2-30 meters

Capacity: 458 cubic meters/hour

Speed: 20-150 rpm

Material: stainless steel

Application: corn, rice, salt, soybeans, flour, starch and other powdered or granular materials.

Promise: Free delivery/5-day delivery/30-day return/customization support

Grain Auger Conveyor is the core equipment of grain storage and transportation system. With its low breakage rate, fully enclosed structure and multi-form adaptability, it is widely used in granaries, processing plants and other scenes. It adopts 316L stainless steel material and wear-resistant ceramic coating technology, which can transport granular materials such as wheat and corn and moisture-prone powder (water content ≤18%).

Grain Auger Conveyor is a kind of equipment specially used for conveying grain. It can solve the problems of scattering and low efficiency in the process of transporting grain. It can convey grain at different angles horizontally, obliquely or vertically to ensure that grain can be quickly transported from one place to different places.

We provide a variety of grain conveying equipment suitable for different types of grains, conveying distances and operating environments.

Hose spiral conveyor: suitable for powdered and granular grains, such as flour, soybean meal, rice bran, feed, etc., using high-strength wear-resistant hoses, can be bent for conveying, and adapt to complex spatial layouts. Fully enclosed conveying to avoid dust spillage, in line with environmental protection requirements. Suitable for short-distance (3-30 meters) and small-batch conveying, easy to move.

Belt conveyor: suitable for granular grains, wheat, corn, rice, soybeans, suitable for long-distance (10-100 meters) and large-scale continuous conveying. The belt is soft and does not damage the grain, especially suitable for seed grain conveying. The maximum inclination angle is ≤25°, which is suitable for loading, warehousing and other scenarios.

U-shaped screw conveyor: suitable for granular and small-block grains, such as corn, wheat, beans, and feed pellets. The U-shaped trough design prevents leakage and is suitable for medium and long-distance transportation (5-30 meters). It can be horizontal or inclined (≤20°) to adapt to different working conditions.

Meet the hygiene standards: The whole machine is made of stainless steel, which can ensure that the grain is not contaminated during the transportation process.

Convenient to move: The roller design at the bottom of the conveyor can be moved to the designated position at any time.

Strong adaptability: It can adapt to conveying at different angles, with high flexibility and suitable for a variety of process requirements.

No dust pollution: The closed design can avoid scattering and dust pollution during the conveying process.

Grain screw conveyor plays an important role in the grain industry. Its main functions and roles include but are not limited to the following points:

Conveying grain: The main function is to convey grain from one location to a warehouse, production line or processing equipment, which can be conveyed horizontally, obliquely or vertically.

Conveying of production line: Grain can be conveyed from processing links such as cleaning, crushing, screening, drying, etc. to the next process.

Improve production efficiency: The emergence of grain screw conveyors has greatly reduced the time and labor costs in the material transportation process.

Reduce grain loss: Through stable and uniform transportation, the vibration and loss of grain during transportation can be reduced, and the quality of grain can be maintained.

Different grain spiral conveyors can be used according to their own advantages

Grains: wheat, corn, rice, barley, sorghum, good fluidity, suitable for standard spiral design, need to control the speed to prevent breakage (especially rice)

Beans: soybeans, mung beans, red beans, peas, hard particles, need wear-resistant blades, soybeans are easy to roll, it is recommended to reduce the inclination angle (<20°).

Oil crops: rapeseed, peanuts, sunflower seeds, small particles (such as rapeseed) need to be leak-proof design; peanuts and other fragile materials need to run at low speed.

Whole grains: oats, buckwheat, quinoa, light particles need to reduce the speed to avoid dust

Processing by-products: bran, rice bran, soybean meal, high dust, need closed design and equipped with dust removal interface

Seeds: breeding corn, hybrid rice seeds, strict low damage transportation, double spiral flexible push is recommended (breakage rate <0.3%).

Materials not suitable for conveying

Sticky materials: such as wet flour, grains soaked in syrup (easy to adhere to spiral blades).

Perishable materials: high-moisture grains (moisture content > 18%), which may cause mold and blockage.

Extreme-shaped materials: extra-long fibers (such as straw) or extra-large lumps (such as unbroken corn cobs).

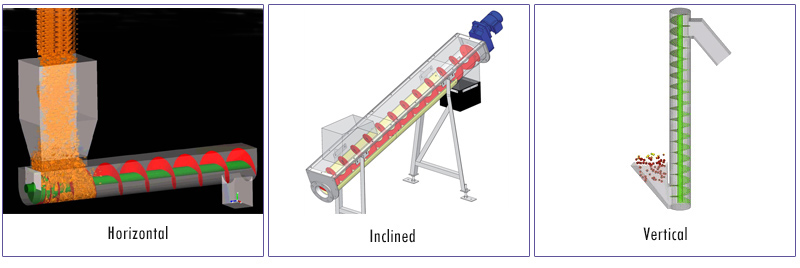

Different inclination angles

Horizontal screw conveyor: Applicable to the scene of horizontal grain feeding, the conveying length can reach 20 meters

Oblique screw conveyor: The inclination angle can be between 10° and 60°, mainly used for inclined direction transportation.

Vertical screw conveyor: It can be used to convey grain vertically from the ground to the production line or silo above, and the vertical height can reach 6 meters.

| Model | LS114 | LS133 | LS159 | LS219 | LS245 | LS273 | LS315 | LS400 | LS500 | LS600 |

| Diameter(mm) | 114 | 133 | 159 | 219 | 245 | 273 | 315 | 400 | 500 | 600 |

| Rated speed(r/min) | 84- 130 | 84- 130 | 84- 130 | 84- 130 | 84- 130 | 84- 130 | 84- 130 | 62-100 | 62-100 | 62-100 |

| Reference capacity | 1 | 1.3 | 5 | 15 | 20 | 30 | 40 | 45 | 70 | 100 |

| Motor power(Kw) | 2.2-18.5 | |||||||||

| Admission biggest gradient(o) | <60 | |||||||||

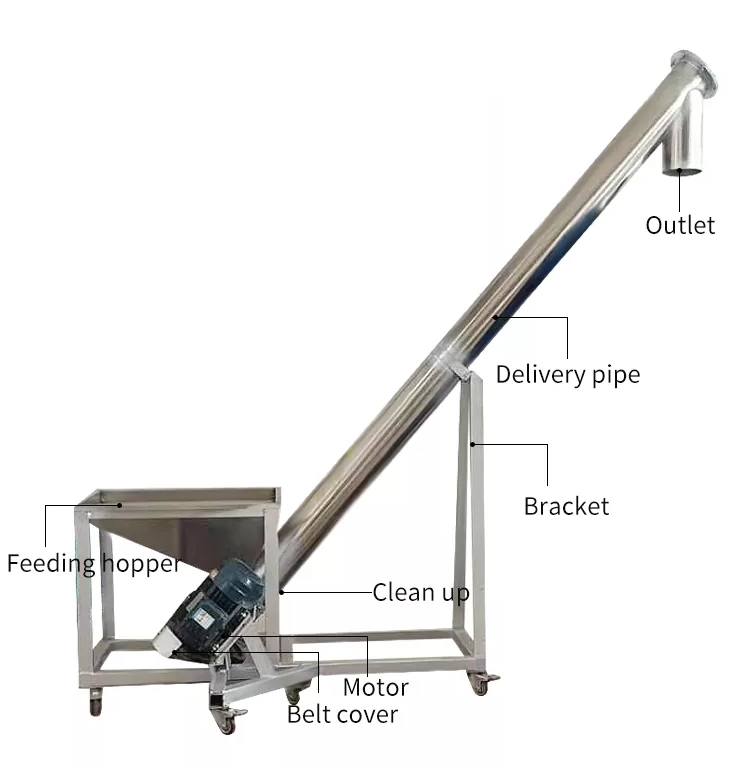

The structure of grain screw conveyors is relatively simple, usually consisting of the following main parts:

Spiral blades: Spiral blades are an important component of the screw conveyor. It is inside the spiral tube. The grain spiral blades are generally axial spirals, which are convenient for pushing grains for transportation.

Conveying trough: The conveying pipeline is the outer shell of the screw conveyor, which is used to accommodate the spiral blades and guide the conveying direction of grains.

Support frame: The support frame is used to support and fix the various components of the screw conveyor to ensure the stable operation of the equipment.

Feed port silo: Mainly used to put and store grain materials to ensure the continuity of grain during transportation.

Discharge port: Responsible for smoothly discharging the grains from the feed port to the designated location.

Grains are put into the screw conveyor through the feed port, and the rotating movement of the spiral blades pushes the grains forward along the conveying pipe, and finally discharged to the required position along the direction of the spiral pipe.

Our grain screw conveyors have been well received by customers. The following is customer feedback.

| Materials | Conveying length | Angle | Transport capacity | Material |

| food | 2.7 m | Horizontal conveying | 3 tons per hour | Stainless steel |

| food | 20m | Tilt 30° | 2.2 tons per hour | Stainless steel |

| food | 4m | vertical | 1 ton per hour | Stainless steel |

| food | 25m | Horizontal conveying | 20 tons per hour | Stainless steel |

| food | 4.5m | Tilt 30° | 2 tons per hour | Stainless steel |

When choosing a suitable grain screw conveyor, you can combine your own situation and consider the following factors:

Grain characteristics: Consider the size, viscosity, and humidity of the grain particles to be transported to determine the required conveying capacity and conveying speed.

Conveying distance and height: Check the on-site conveying distance and inclination or vertical height according to the conveying requirements to select the appropriate length and inclination angle.

Production capacity: Determine the required production capacity according to the needs of the production line to determine the diameter of the conveying pipeline.

Dahan Machinery Conveying Equipment Factory strictly selects high-quality materials for the production of screw conveyors, and uses wear-resistant and corrosion-resistant stainless steel materials to ensure that the conveyor has a long service life and can adapt to various environmental conditions. The company introduces advanced welding technology and equipment to ensure the welding quality and stability of the screw conveyor, and ensures that the welding joints of each conveyor are uniform and firm, in line with relevant standard requirements. The company follows the ISO quality management system to ensure stable and reliable product quality and provide customized solutions to meet customer specific needs.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!