Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

It is used for the transportation and mixing of raw materials in the feed industry. The fully sealed structure can avoid the contamination of raw materials during transportation and reduce the flying of dust.

Price: $450.00 - $3,200.00/Set Chat Now

Delivery capacity: 458 cubic meters per hour

Conveying length: 70 meters

Application materials: various bulk feeds, such as: pig feed, cattle feed, fish feed, chicken feed and other powders, granules

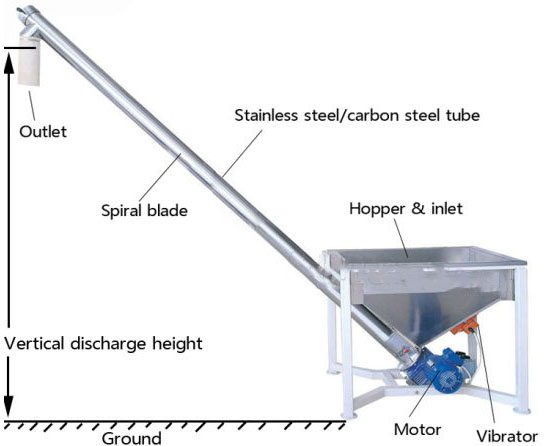

Feed Screw Conveyor should be used in the conveying and mixing of raw materials in the feed industry. The hopper of the screw conveyor feeds the feed, and the plastic is sent to the discharge end of the conveyor by the screw shaft, and the feed is filled into bags at the discharge end. Feed Screw Conveyor can be arranged horizontally, inclined or vertically. It can be used as a single machine or in combination with multiple machines. It can also be used in conjunction with other equipment to meet the conveying requirements of various industries.

Note: 304/316 stainless steel can be selected according to user requirements, which is more hygienic.

Vertical conveying of feed

Feed Screw Conveyor is mainly used in various feed industries, and can transport powdery or granular feeds, such as soybeans, soybean meal, corn, fish meal, amino acid, miscellaneous meal, whey powder, oil, meat and bone meal, grain, feed additives, etc.

1. Using adjustable speed motor, the conveying volume can be easily adjusted at will, and the feeding is uniform.

2. The conveying capacity per hour can reach 458 cubic meters per hour, and the conveying length can reach 3-70 meters.

3. Single-point or multi-point feeding, flexible layout, and can also transport materials to two directions at the same time.

4. The surface of the screw conveyor is surrounded by a shell, which can prevent the feed material from being polluted.

When the feed enters the Feed Screw Conveyor from the feed port, when the screw shaft rotates, the feed is affected by the thrust of the screw blades, and the radial component of the thrust and the friction of the blades on the material will drive the material to rotate around the screw shaft, but due to Due to the gravity of the material itself and the frictional force of the trough on the material, it does not rotate with the helical blade, but moves along the axial direction of the trough under the axial component of the blade's reverse thrust.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

Feed Screw Conveyor is mainly composed of driving device, casing, cover plate, screw shaft, screw blade, feed inlet, feed outlet and other components.

Drive device: It consists of a motor and a reducer.

Spiral blade: It can be divided into several forms such as full blade type, blade type, paddle type, and tooth type.

Chassis: There are two types of "U"-shaped casing and circular casing. The circular casing is mainly used for feeding the sealing equipment. The auger of the circular casing is also called the sealing auger.

Screw shaft: hollow, made of steel pipe, high strength, light weight, easy to connect. Use a short length of solid shaft at the shaft-to-shaft connection and where you mount the bearings. Extend the solid shaft into the hollow shaft at the joint and use high-strength bolts to pass through the hollow shaft and the solid shaft in a mutually perpendicular direction to fix and connect the helical shaft.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!