Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

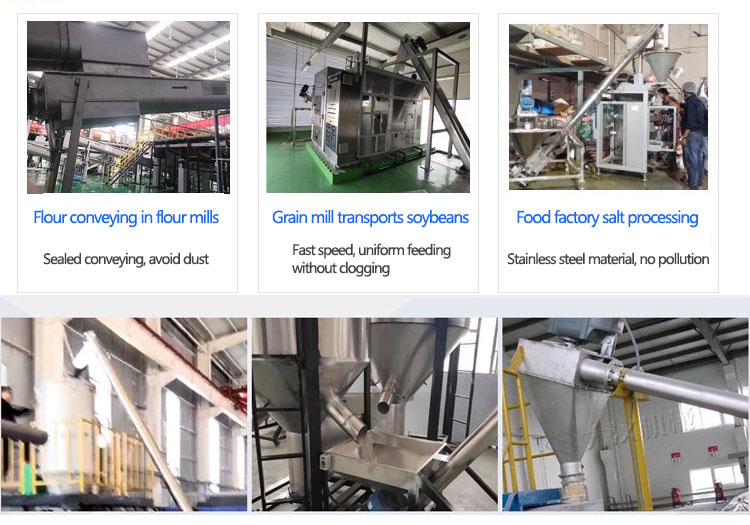

Grain Screw Conveyors are made of 304/316L stainless steel, clean and hygienic, and can be used for conveying various bulk grains in the grain industry.

Price:$350.00-$3,060.00/Set Chat Now

Diameter: 100mm-1250mm

Length: 2-70 meters

Capacity: 458m³/h

Material: Stainless steel

Materials: peanuts, rice, corn, paddy, wheat, salt, soybeans, flour, starch, etc.

Grain Screw Conveyors are modern conveying equipment dedicated to the grain industry. They are made of high-quality 304 stainless steel and fully comply with food-grade hygiene standards. They have a variety of pipe diameters from 100mm to 1250mm, with a maximum conveying length of 30 meters and a conveying capacity of up to 458 cubic meters per hour, which can meet the production needs of grain companies of different sizes. They can flexibly realize horizontal, inclined (up to 30 degrees) or vertical conveying, and are particularly suitable for grain in and out of warehouses, material flow of processing production lines, bulk grain loading and unloading vehicles and ships, and grain cleaning and grading.

We supply various types of grain screw conveyors to meet your different needs, including tubular grain screws and hose screws.

Grain screw conveyors: can be transported horizontally, tilted, and vertically, mainly used to transport grains similar to powder. The grain conveyor belt can be placed in a designated position or packaging machine. The tilt angle can reach 45°, the conveying length can be 3-30 meters, and the conveying volume can be 2-20 cubic meters.

Hose grain spiral conveyor: can be bent at will to change the conveying position, can provide a length of 3-30 meters, the output can reach 2-15 tons per hour, can be equipped with a stainless steel handheld discharge port, and can well control the discharge direction. Provide electric and diesel drive modes, motors include two-phase and three-phase electricity.

Conveying flour

Conveying grain

Conveying corn

Conveying wheat

Grain spiral conveyors are particularly suitable for medium and short-distance transportation of granular grains such as wheat and corn due to their stable mechanical conveying characteristics. Their 304 stainless steel material fully complies with food hygiene standards, and their closed structure can effectively control dust. Their conveying capacity can reach up to 458m³/h, making them the main equipment on grain processing production lines. Hose conveyors are known for their excellent flexibility. They use food-grade wear-resistant hoses as conveying channels, which can easily realize multi-angle and multi-station material transfer. They are particularly suitable for operation scenarios such as granaries and docks that require frequent changes in conveying positions. The two types of equipment are often used in conjunction in grain storage and transportation systems: the spiral conveyor is responsible for stable transportation on the production line, while the hose conveyor completes flexible operations such as loading and unloading vehicles. Modern intelligent control systems can also realize the linkage operation of the two types of equipment, and automatically switch the conveying mode according to actual production needs through PLC centralized control.

The spiral blades are flexible and adjustable, and horizontal, inclined, and vertical conveying can be switched freely; the modular structure is easy to install and maintain, and is suitable for large and small production lines.

Body material: selected 304 stainless steel material, anti-corrosion, anti-rust, in line with food production hygiene standards.

Large conveying capacity: all kinds of powder and granular grain conveying, the output can reach 458 cubic meters per hour.

Conveying distance: The conveying length of a single machine can reach 30m, and the segmented installation can reach 100m.

Sealing structure: The fully enclosed and easy-to-clean spiral surface can ensure that the food will not be polluted or leaked.

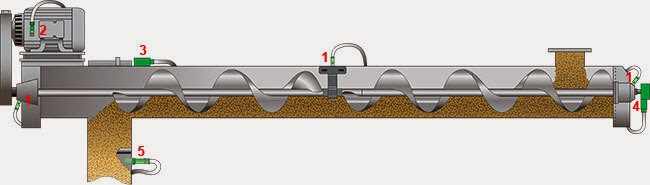

When Grain Screw Conveyors work, they rely on the rotating helical blades to push and transport the grain. The force that makes the grain rotate with the helical blades is the weight of the grain itself and the frictional resistance of the screw conveyor casing to the material. The movement of the grain in the middle bearing depends on the thrust of the grain moving forward in the back. Therefore, the transportation of grain in the screw conveyor is completely a sliding movement.

| Specifications | Spiral diameter(mm) | Pitch (mm) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | Speed(r/min) | Delivery capacity(m³/h) | |

| small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3.0 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| medium | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62.0 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

The grain screw conveyor is composed of multiple components, each of which has a specific function and works together to complete the material conveying task. The following are the main components of the grain screw conveyor:

Screw body (screw shaft): The screw body is the core part of the grain screw conveyor, which is composed of a screw shaft and is responsible for rotating and conveying the material along the screw shaft.

Feed port: The feed port is the starting point for material loading, and the grain or granular material to be conveyed is loaded into the conveyor.

Discharge port: The discharge port is the outlet of the material. After the material is conveyed, the grain or granular material leaves the conveyor through the discharge port.

Bearing support: The bearing support plays the role of supporting and fixing the screw shaft to ensure the stable rotation of the screw shaft.

Transmission device: The transmission device provides power through a motor or other power source to drive the screw shaft to rotate and push the material for conveying.

Casing (pipeline): The casing or pipeline is the outer shell of the screw conveyor, which wraps the screw shaft to prevent material from spilling or splashing.

We are a professional grain screw conveyor manufacturer, committed to providing customers with high-quality and reliable conveying solutions. We have advanced production equipment and a technical team that can produce a variety of screw conveyors, including traditional grain screw conveyors and hose grain screw conveyors. We provide customized services and customize screw conveyors that are suitable for the production process and site requirements of customers according to their specific needs. Whether it is special size, special material or special function requirements, we can meet your needs. Choosing us, you will get high-quality products and services and achieve a win-win situation.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!