Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

A Grain Suction Machine is a mechanical device used to collect crops, mainly for threshing, removing scum, and conveying grain into containers or vehicles. It has a simple structure and high precision, and can complete a large number of operations in a short period of time.

The working principle of the Grain Suction Machine is based on air conveying. The Grain Suction Machine utilizes an internal fan to create a pressure differential in the pipe, which draws in air and transports the grain through the curved pipe into the container by suction. The principle is similar to that found in household vacuum cleaners, which induce airflow through a fan, which in turn picks up dust and small particles.

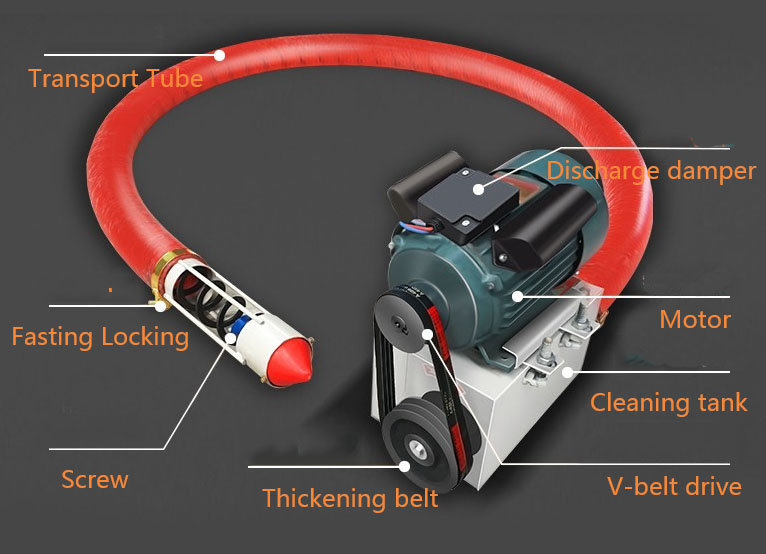

The structure of Grain Suction Machine can be divided into the following parts:

The driving mechanism of Grain Suction Machine includes engine and transmission. As a main power source, the engine provides power for the grain suction machine so that it can operate normally. The transmission is mainly used to adjust the speed of the grain suction machine to adapt to different working environments.

The input drive system of the Grain Suction Machine is to transmit the power generated by the engine to the driving shaft of the grain suction machine, thereby driving the suction fan and centrifugal pump. The system includes main clutch, gear transmission and so on.

The centrifugal pump and nozzle are the core parts of the grain suction machine. Centrifugal pumps help separate air and grain while preventing wear and clogging during delivery. The nozzle is used to control the way and speed of the airflow in the process of grain flying into the dust, so as to ensure the conveying and threshing effect of grain.

The pipeline system is a relatively important part of the grain suction machine, and damage or blockage will have a serious impact on the operation. Its function is to determine the pipeline length and internal structure of the entire Grain Suction Machine according to the number and distance of the rice threshers. Through the structural design of the length and curvature of the pipeline, the airflow speed and direction are adjusted to complete grain transportation and threshing.

Dust suction system and control device are relatively common accessory equipment in grain suction machines. The main function is to absorb the lye in the grain to make the grain more pure. During the conveying process, due to the impact and friction of the airflow, more dust and debris are generated. The dust suction system can effectively capture and remove these dusts to prevent them from clogging the Grain Suction Machine or causing injury to the workers.

Overall, the construction of Grain Suction Machines is diverse, but most of them use similar working principles and core components. The structure and principle of the Grain Suction Machine depend on the needs of the actual application and the specific working environment.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!