Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

For concrete mixing plants, stabilized soil mixing plants, and cement plants, the concrete has the functions of conveying, mixing, stirring, loosening, heating, cooling, etc., preventing agglomeration and not jamming materials; it adopts a double-pitch design of one-time forming helical blades, which can Avoid concrete segregation and ensure continuous discharge.

Price: $800.00-$5,320.00/Set Chat Now

Diameter: 165mm, 219mm, 273mm, 323mm, 407mm

Delivery capacity: 458 cubic meters per hour

Length: 60 meters

Select the angle within 15° within 90°

Materials: concrete, cement, fly ash, ash, coke,coal powder, sand, etc.

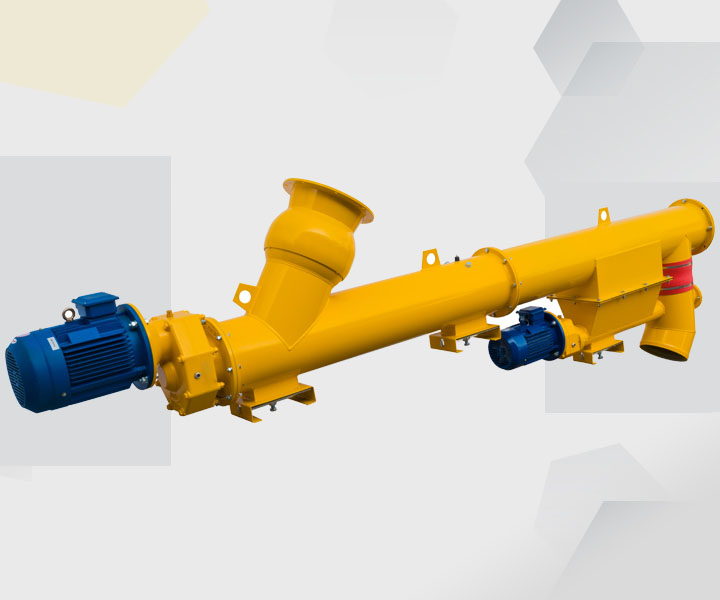

Concrete Screw Conveyor is specially designed for concrete mixing stations and building materials processing plants. It can achieve efficient transportation of concrete and concrete-like materials at a rate of 15-30 cubic meters per hour. The surface is treated with sandblasting and double-layer epoxy powder coating to enhance wear resistance and corrosion resistance. Whether it is horizontal transportation or maximum 45° inclined transportation, the equipment can maintain a stable and efficient operating state. At the same time, it can be seamlessly connected with mixers, batching machines and other equipment to build an integrated material transportation system.

Concrete Screw Conveyor is mainly used for conveying concrete and concrete-like materials in concrete mixing plants and other building material processing plants. The outer tube is made of carbon steel, which has good overall rigidity and has proper surface treatment and powder coating. Wan is optional The ball joint makes it easy to install and adjust the steering. It can be transported horizontally or inclined. It is flexible in combination and can be used with a variety of equipment.

As a special type of screw conveyor, concrete screw conveyor is widely used in the construction industry. Due to the particularity of concrete (viscous, easy to precipitate, and highly abrasive), the requirements for conveying equipment are also higher.

Classification by structural form

Horizontal screw conveyor: mainly used for conveying concrete in the horizontal direction, with a simple structure and easy installation and maintenance.

Inclined screw conveyor: used to convey concrete to high places or different horizontal positions, with adjustable angles and strong adaptability.

Vertical screw conveyor: used for vertical conveying of concrete, commonly used for concrete supply in multi-story buildings.

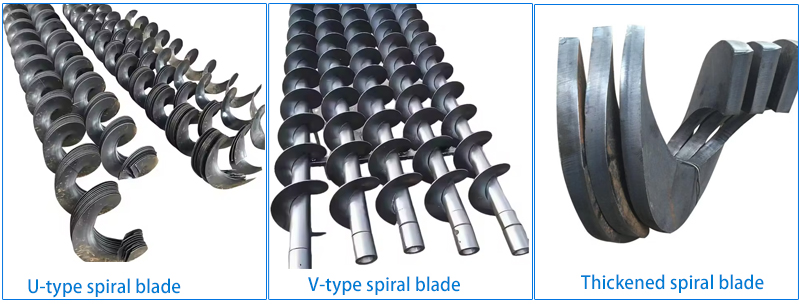

Classification by spiral blade shape

U-type spiral blade: suitable for conveying ordinary concrete, with strong carrying capacity.

V-type spiral blade: suitable for conveying concrete that is easy to agglomerate to prevent blockage.

Thickened spiral blade: suitable for conveying highly abrasive concrete to extend service life.

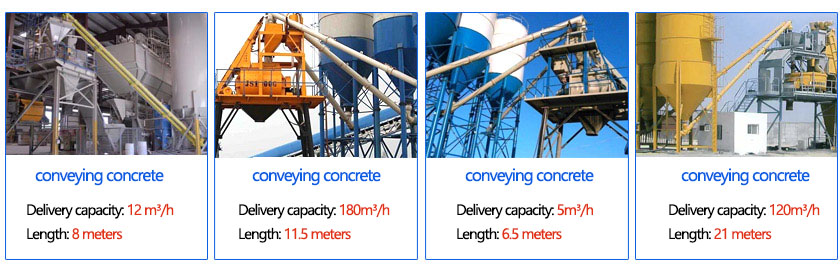

Concrete Screw Conveyor is mainly used for conveying concrete, cement, fly ash, fine sand and other powder materials and fine granular dry materials. It is often used in mixing plants, cement plants, and mining industries.

Concrete production: Concrete screw conveyors can transport concrete from mixing plants to construction sites, improving production efficiency.

Cement plants: Used to transport raw materials or finished products such as cement and limestone in cement plants.

Mining industry: Commonly used to transport ore, tailings, coal and other materials in the mining industry.

Fly ash processing: For fine powder materials such as fly ash, concrete screw conveyors can efficiently transport and process them, which are commonly found in coal-fired power plants and other industrial sites.

Fine sand transportation: For fine-grained dry materials such as fine sand, concrete screw conveyors can also effectively transport and process them, and are often used in occasions such as the building materials industry and sand fields.

The concrete spiral conveyor belt has large-volume and long-distance transportation capabilities. Its versatility enables it to perform stirring, mixing and other operations during transportation.

Large-volume and long-distance: The transportation capacity is up to 458 cubic meters per hour, and the transportation length can reach 30 meters. It can be installed in series in multiple stages to achieve longer distance material transportation.

Anti-blocking design: Double spiral blades are used to reduce the degree of compression during concrete transportation and effectively prevent material blockage.

Multi-function transportation: While conveying materials, stirring, mixing, heating and cooling processes can be carried out to avoid the aggregation of concrete during transportation.

Adapt to harsh environments: Equipped with anti-adhesion devices to prevent material moisture and agglomeration, ensuring normal operation in humid environments such as rainy days.

Flexible conveying direction: Intermediate loading and unloading can be achieved, and materials can be conveyed in reverse or bidirectional directions at the same time.

When the Concrete Screw Conveyor is started, it drives the screw shaft to rotate. Due to the gravity of the concrete and the friction between the wall of the tank, the concrete can only move forward along the bottom of the conveyor under the push of the blade until it comes out. The feed port is discharged.

| Model | LSY165 | LSY219 | LSY273 | LSY325 |

| Shell Diameter(mm) | 165 | 219 | 273 | 325 |

| Screw Diameter(mm) | 135 | 189 | 243 | 295 |

| Conveying Length(m) | 2-12 | 2-12 | 2-12 | 2-12 |

| Rotation Speed (r/min) | 300 | 200 | 209 | 174 |

| Working Angle (°) | 0-45 | 0-45 | 0-45 | 0-45 |

| Conveying Capacity (t/h) | 25 | 35 | 50 | 75 |

| Motor Type | Y100L-4 | Y132M-4 | Y160M-4 | Y180M-4 |

| Motor Power (kw) | 5.5-7.5 | 5.5-11 | 7.5-15 | 7.5-18.5 |

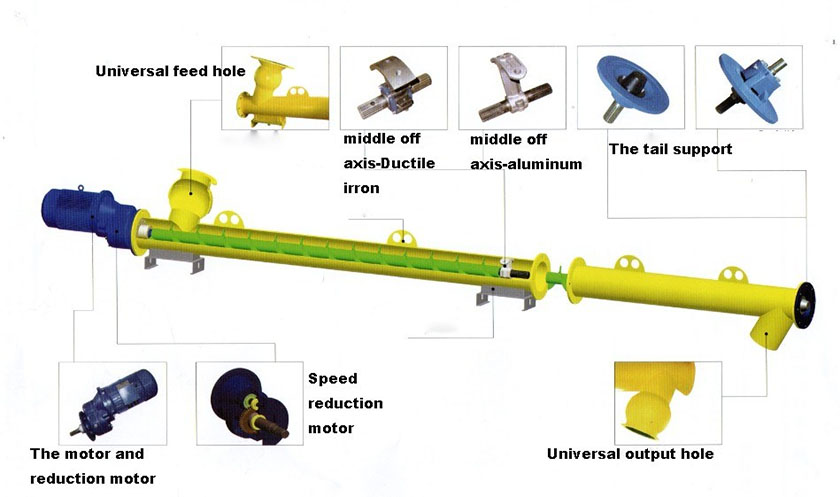

The concrete screw conveyor consists of a drive unit, a spiral shaft, a feeding and discharging device and other structures. It is suitable for working conditions of -20℃~60℃ and is an ideal conveying equipment for concrete production plants.

Spiral shaft: It is the core component of the spiral conveyor belt, usually a long shaft with spiral blades installed on it.

Spiral blades: Welded or assembled on the spiral shaft, it is a component that directly pushes the concrete material. Its shape and size are designed according to the characteristics and conveying volume of the conveyed material.

Casing: Also known as casing, it is the outer shell of the spiral conveyor, generally made of carbon steel and other materials.

Cover: Installed on the top of the casing, used to close the casing to prevent dust, debris, etc. from entering the conveying system, and also facilitate the inspection and maintenance of internal components.

Feed port: Located at one end of the casing, it is the entrance for concrete materials to enter the spiral conveyor.

Discharge port: Located at the other end of the casing or other suitable position, it is the outlet for concrete materials to be transported to the designated location.

Optional devices: According to different usage requirements, some optional devices may also be equipped, such as valves for adjusting material flow, devices that can stir, mix, heat or cool materials during transportation, and moisture-proof devices to prevent moisture and agglomeration of materials.

From core parameters to detailed configuration, this guide helps you select accurately, avoid problems such as low conveying efficiency, blockage, and high loss, and unlock efficient concrete transmission solutions.

Core parameter matching: Determine the conveying capacity (50-200m³/h) and conveying distance (U-shaped trough for short distance and pipe type for long distance) according to the project requirements, and consider the inclination angle (≤30° conventional inclination) and concrete characteristics (aggregate ≤50mm, slump 80-180mm) to ensure that the equipment and working conditions are accurately adapted.

Structural type selection: Conventional concrete is preferably economical shafted spiral; fiber-containing or easy-to-block material conditions use shaftless spiral design. The sealing level is selected according to environmental protection requirements. Fully enclosed (dust-proof) or open (easy maintenance).

Material and durable configuration: Rotary blades are recommended to be 65Mn wear-resistant steel or surfacing treatment, and the trough/pipeline is selected according to the environment. Carbon steel or stainless steel. Wear-resistant design can increase the life of the equipment by more than 3 times and significantly reduce long-term operation and maintenance costs.

Function optimization suggestions: Additional anti-segregation blades, high-pressure cleaning interfaces and variable frequency speed regulation functions can meet the needs of aggregate separation, residue cleaning and beat adjustment. It is recommended to give priority to suppliers that support customized services.

The cost of a concrete screw conveyor mainly depends on the equipment specifications, material configuration and functional requirements. The small basic model is suitable for short distance and low conveying volume scenarios. It is made of standard carbon steel material, has a simple structure and low maintenance cost, and is suitable for small and medium-sized projects with limited budgets. Medium-sized equipment is usually equipped with wear-resistant blades and anti-segregation design, which is suitable for medium conveying volume and conventional engineering needs, and strikes a balance between durability and functionality. Large high-end models adopt an all-stainless steel structure and integrate advanced functions such as frequency conversion control and automatic cleaning to meet the harsh working conditions of long distance and large conveying volume. Although the initial investment is high, long-term use can significantly reduce maintenance and energy consumption costs. For special needs (such as explosion-proof, corrosion-resistant or customized inclination), the cost will increase accordingly. Users can provide the project scale, concrete characteristics and frequency of use, and we will recommend a suitable model for you and quote.

Dahan Concrete Culvert Screw Conveyor covers various types of concrete screw conveyors, including horizontal, vertical, inclined and other types to meet the needs of customers in various scenarios. We use high-quality materials to manufacture, with a stable structure, smooth and reliable operation, ensuring long-term efficient work. Concrete screw conveyors of different specifications and models can be customized according to customer needs to meet the specific requirements of different scenarios. If you are looking for a reliable concrete screw conveyor manufacturer, welcome to contact us, we will wholeheartedly provide you with quality products and services.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!