Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Powder screw conveyor pushes the powder or granular materials horizontally or obliquely along a certain direction through the rotation of the spiral blades on the spiral shaft. It is suitable for various powder or granular materials, such as flour, sand, chemical powder, food raw materials, etc.

We can provide customers with different types of screw conveyors to meet your conveying needs.

Flexible screw conveyor: It has a certain degree of softness and can be bent arbitrarily. It can flexibly adjust the conveying height and is suitable for occasions where materials need to be conveyed at different heights.

Stainless steel screw conveyor: Made of stainless steel, it has the characteristics of corrosion resistance and easy cleaning, and is suitable for occasions with high hygiene requirements.

Double-axis screw conveyor: It has two screw shafts and can convey materials more stably. It is suitable for occasions with large conveying volume and high stability requirements.

Vertical screw conveyor: It is designed for vertical material conveying and can realize ascending or descending conveying, such as conveying from the ground to the upper floor or from the upper floor to the ground.

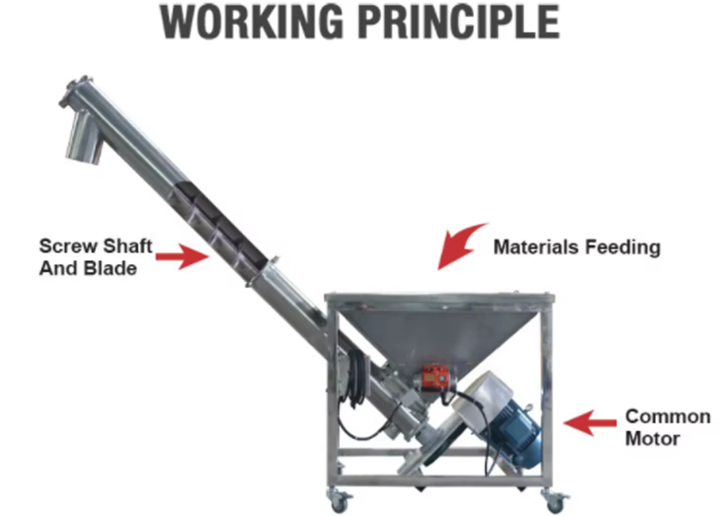

Powder screw conveyor is a mechanical device mainly used to convey powder or granular materials in a certain direction. The following is the working principle of powder screw conveyor:

1. Feed port: The material enters the conveying pipe of the screw conveyor through the feed port.

2. Spiral blade push: Inside the conveying pipe, the spiral blades installed on the spiral shaft begin to rotate. The rotation of these spiral blades pushes the material forward.

3. Material conveying: The material is wrapped by the spiral blades and is pushed forward along the direction of the conveyor as the spiral shaft rotates.

4. Discharge port: Finally, the material reaches the discharge port and is released from the conveyor to complete the conveying process.

The powder screw conveyor is a mechanical device composed of multiple components. Its main components usually include the following parts:

1. Screw shaft: It is the core component of the conveyor and is responsible for transmitting power and rotational force.

2. Spiral blade: It is installed on the screw shaft and is responsible for pushing the material along the direction of the conveyor. It is mostly spiral-shaped and helps to wrap and push the material.

3. Conveying pipeline: It provides a channel for material transportation and maintains the directionality of the material during the transportation process. It has carbon steel, stainless steel or other special materials.

4. Transmission device: It provides the power required by the screw shaft to drive the spiral blade to rotate.

| Model | DJ-S3 | DJ-S1 |

|---|---|---|

| Capacity | 3-5m3/h | 1 m³/H |

| Hopper Size | 230L | 100L |

| Machine Power | 1.8Kw | 1.1Kw |

| Power Supply | 3p-380V 50-60Hz | 380V1220V 50-60Hz |

| Packaging Speed | 1870mm from floor | 1600mm from floor |

| Machine Weight | 150K9 | 80Kg |

Powder screw conveyor is a general conveying equipment suitable for many different industries and fields. The following are some common application industries of powder screw conveyor:

Chemical industry: commonly used for conveying powder and granular materials in the chemical industry, such as fertilizers, plastic particles, chemical raw materials, etc.

Food processing industry: commonly used for conveying food raw materials such as flour, powdered sugar, grains, and packaging materials, etc.

Building materials industry: commonly used for conveying construction raw materials such as cement, lime, sand, and concrete products such as concrete and mortar.

Metallurgical industry: used for conveying materials such as ore, metal powder, slag, etc.

Agricultural field: used for conveying agricultural raw materials such as feed, seeds, fertilizers, etc.

Pharmaceutical industry: used for conveying pharmaceutical raw materials such as powder, tablets, capsules, etc.

Powder screw conveyors have many advantages in the industrial and production fields, making them a commonly used conveying equipment. The following are some of the main advantages of powder screw conveyors:

Dust containment: Dust can be contained, which is beneficial to environmental protection and operator health.

Continuous conveying: It can achieve continuous and stable material transportation and improve production efficiency.

Multi-purpose: It is suitable for powder and granular materials of different shapes and properties, such as food processing, chemical industry, building materials, metallurgy, packaging and other industries.

Multiple layouts: It can be arranged horizontally, vertically and tilted to adapt to different site and process requirements.

Space saving: It can be customized according to needs to save site space.

As a professional manufacturer of conveying equipment, we provide a wide variety of screw conveyors and can provide customized solutions according to the specific needs of customers. Whether it is flexible requirements, special material requirements, or specific process needs, we can provide you with high-quality and reliable screw conveyor products. Please feel free to contact us, we look forward to providing you with professional services!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!