Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

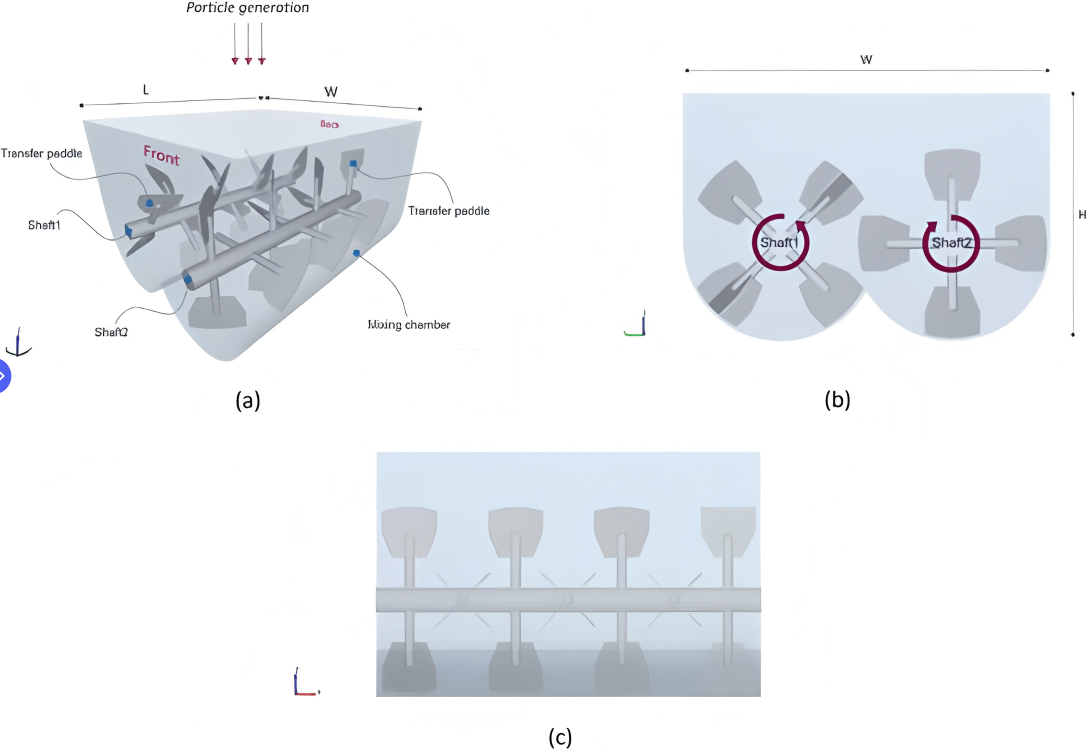

Double Shaft Paddle Mixer is different from ordinary mixers. It has two symmetrical screw shafts, which can break up the agglomerated materials and mix and convey them.

Material type: solid liquid, dry powder, granule

Each processing capacity range: 1000-3000L

Diameter of stirring blade: Φ 450-Φ 600nn

Production capacity: 10-200t/h

Application: used for mixing and mixing of clay, coal slime, nutrient soil, organic fertilizer, etc. in brick factories

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

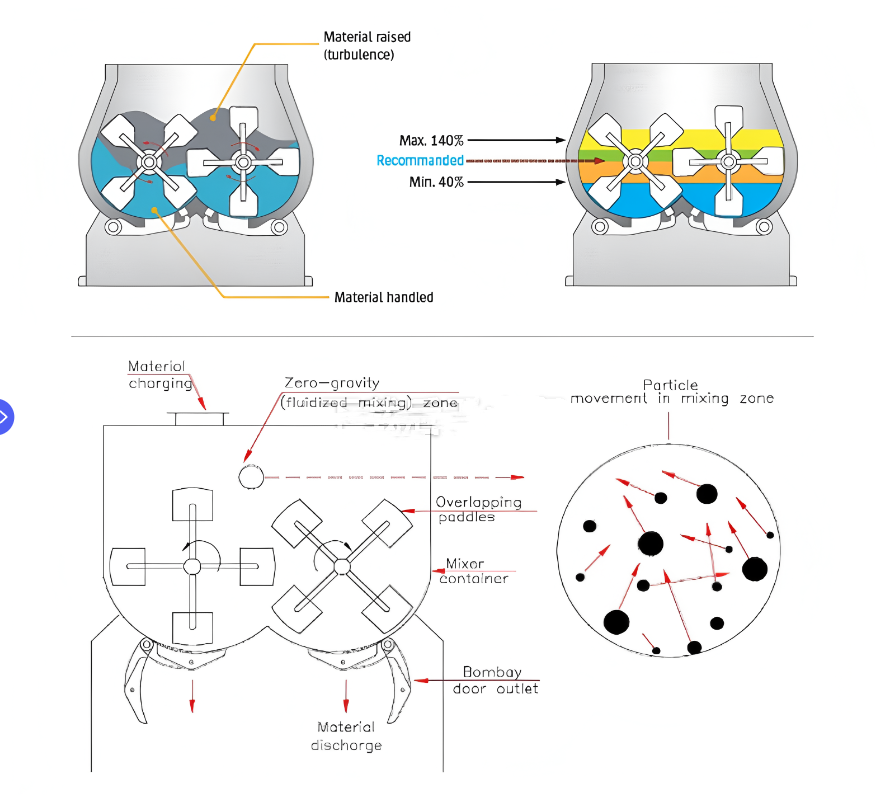

Double Shaft Paddle Mixer achieves high-speed mixing of materials through staggered paddles on two parallel shafts. Its core feature is the bidirectional, differential-speed rotation design that creates complex convection, shear and diffusion motions, allowing powders, granules or viscous materials to be evenly mixed in a short time. It can handle dry and wet materials of different specific gravities and particle sizes, with a mixing uniformity of more than 95%.

Double-shaft paddle mixers have their own advantages and characteristics, making them widely used in various industrial fields.

High mixing uniformity: The paddles are driven by the rotation of the double shafts to mix, which can quickly break up material lumps and improve mixing uniformity.

Low energy consumption: Compared with other types of mixers, double-shaft paddle mixers have lower energy consumption while achieving the same mixing effect.

Continuous production can be achieved: Continuous production can be achieved by adjusting the speed and feed amount to improve production efficiency.

Widely applicable: A variety of materials can be mixed to meet the mixing needs of different processes, including powders, granules, paste materials, etc.

The double-shaft paddle mixer adopts a double-shaft reverse rotation design to drive the paddles to quickly stagger and shear the materials, achieving millisecond-level uniform mixing, and is widely used in different scenarios.

Organic fertilizer: put different organic fertilizers into the spiral machine to mix them fully to produce richer organic fertilizer.

High viscosity solid-liquid mixing: powder or granular materials can be dispersed in liquid for high viscosity mixing, such as preparing suspensions, resins, adhesives, etc.

Organic soil: it can use the paddles to break up the agglomerated organic soil and mix the organic soil better.

Coal: there are some agglomerated coals in coal production, which can be broken up and transported to the designated location by using a double-shaft paddle mixer.

Twin-shaft paddle mixers can usually be divided into the following two main types:

Opposite twin-shaft paddle mixers: This type of twin-shaft paddle mixer has two shafts, each with paddles installed. These blades are usually arranged in opposite directions, that is, they are arranged symmetrically on the axis. When the mixer is running, these opposite blades can effectively push the raw materials in two directions, so as to achieve full mixing.

Co-rotating twin-shaft paddle mixer: Co-rotating twin-shaft paddle mixers also have two shafts, each with paddles, but these paddles rotate in the same direction, that is, they rotate in the same direction on the shaft. This design can produce a stronger stirring effect and quickly mix the raw materials evenly.

The mixer is equipped with two parallel and coaxial rotating shafts. The paddles on the two shafts rotate at high speed in opposite directions. The material produces strong rotation vibration in the paddles, so that the material circulates continuously in the mixing tank and reaches a uniform mixing state in a short time.

There are some differences between a double-shaft paddle spiral mixer and other types of mixers in terms of working principle, mixing effect, and scope of application.

Working principle:

Double-shaft paddle spiral mixer: Use double shafts to drive paddles or spiral blades for mixing and stirring, and use the rotation of paddles or spiral blades to shear, push, and throw materials.

Single-shaft mixer: They do not have the principle of double-shaft mixing, and need to pour different materials all the time during work, and the mixing effect is not good.

Mixing effect:

Double-shaft paddle spiral mixer: Due to the dual-shaft drive, the dual role of paddles or spiral blades can achieve a more uniform mixing effect, which is suitable for mixing a variety of materials.

Single-shaft mixer: Its mixing effect, mixing speed, and mixing uniformity are not as good as double-shaft paddle spiral mixers. If the mixing degree requirement is not high, you can choose it.

Scope of application:

Double-shaft paddle spiral mixer: Suitable for mixing and stirring a variety of materials such as powders, granules, and pastes.

Single-shaft mixer: Due to its single-shaft structure, the mixing powder effect is OK, but if it is a viscous material, it will not achieve a certain mixing effect.

| Double shaft horizontal mixer model | HDWJ2000 | HDWJ2500 | HDWJ3000 |

| production capacity(t/h) | 8 | 10 | 18 |

| Spindle speed(r/min) | 35 | 35 | 35 |

| motor (kw) | 7.5kw4class | 11kw4class | 15kw4class |

| Dimensions (L×W×H) |

3100x750x500 | 4200x800x620 | 4700x800x620 |

| equipment weight(kg) | 1600 | 2500 | 3200 |

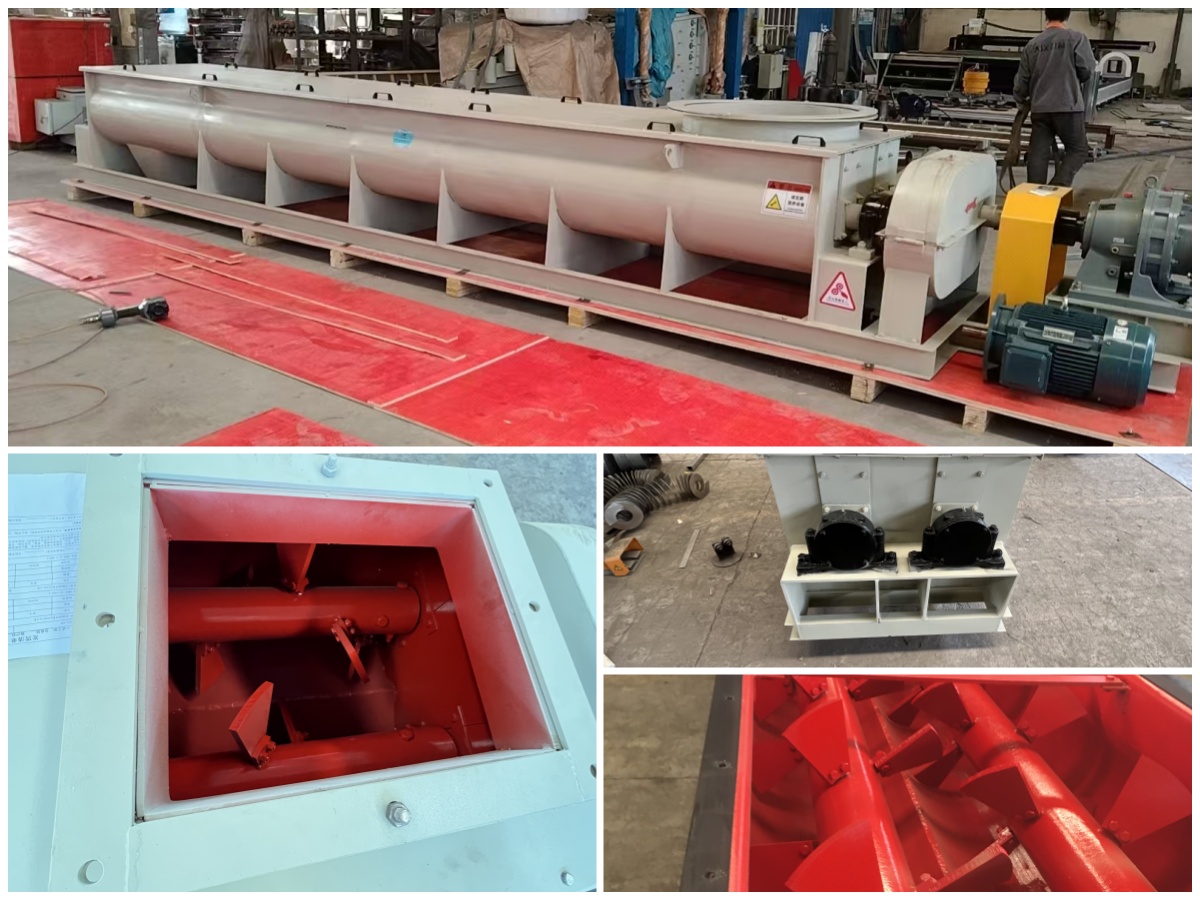

Twin-shaft paddle mixer is a common mixing equipment, and its main structure usually includes the following parts:

Frame: Provides a frame structure to support and fix the various parts of the mixer to ensure the stability of the whole machine.

Twin-shaft: Usually has two horizontal or inclined shafts for driving paddles or spiral blades.

Paddles or spiral blades: Installed on the twin shafts, the materials are mixed, stirred, homogenized, etc. through the rotation of the twin shafts.

Stirring chamber: When the paddles or spiral blades rotate, the space formed is used to place materials and mix and stir.

Transmission device: Including motors, reducers and other equipment, used to provide power and drive the twin shafts to rotate, driving the paddles or spiral blades for mixing and stirring.

The double-shaft paddle mixer is designed based on the principle of efficient convection and shear mixing. The equipment has two parallel stirring shafts built in, and multiple sets of paddles are staggered on the shafts, which are driven by motors to achieve reverse synchronous rotation. This "convection + shear" composite effect greatly shortens the mixing time and significantly improves the mixing uniformity. It is especially suitable for efficient mixing of high-viscosity, multi-component complex materials, and exhibits excellent mixing performance in the chemical, feed, building materials and other industries

Choosing a twin-shaft paddle spiral mixer suitable for your product requires consideration of multiple factors, including product properties, production requirements, process parameters, etc.

Understand the properties of the product: First, you need to understand the properties of your product, including viscosity, density, particle size, etc.

Determine the production volume: Determine the specific requirements for mixing effect, mixing speed, capacity requirements, etc. in production, so as to select the appropriate specifications and models of the twin-shaft paddle mixer.

Seek professional advice: If you are not sure how to choose a suitable twin-shaft paddle mixer, you can contact us at any time and we will design a plan for you free of charge.

From precisely preparing nutritional formulas in the feed industry to achieving rapid dispersion of high-viscosity materials in the chemical industry; from efficiently mixing mortar aggregates in the building materials industry to ensuring fine and uniform raw materials in the food industry, the twin-shaft paddle mixer breaks through the industry's mixing problems with its powerful convection and high-speed shear.

Chemical industry: Able to handle high-viscosity and corrosive materials to ensure uniform mixing.

Food industry: Able to quickly and evenly mix various food raw materials to ensure the taste and quality of food.

Pharmaceutical industry: Able to meet the requirements of mixing uniformity and sterility in drug production.

The twin-shaft paddle mixer is a highly efficient mixing equipment, commonly used in the production of chemical, pharmaceutical, food and other fields. As a professional twin-shaft paddle mixer manufacturer, we are committed to the research and development and production of high-quality mixing equipment. From raw material procurement to finished product delivery, we implement a strict quality control system to ensure that each twin-shaft paddle mixer is of high quality. The product has the advantages of high mixing efficiency and good uniformity, and can achieve all-round mixing of materials in a short time, with a mixing accuracy far exceeding that of its peers. At the same time, exclusive equipment can be customized in terms of material selection, capacity, functional configuration, etc. according to customer needs.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!