Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Flexible Screw Conveyors is an innovative material handling equipment. Through the innovative design of shaftless spiral spring and polymer composite hose, it completely subverts the rigid limitations of traditional conveying equipment. Its unique three-dimensional flexible deformation ability can realize ±30° arbitrary angle bending and conveying, perfectly solving the layout problem of complex plant space; the fully enclosed conveying structure combined with food-grade material selection strictly controls the dust leakage to <1mg/m³, easily meeting international certification standards such as FDA and GMP.

The handheld and vehicle-mounted flexible screw conveyors launched by our company are carefully designed to meet various material conveying problems and inject powerful support into your production operations.

Handheld flexible screw conveyor: specially designed for scenes that require frequent movement and small-scale operations. The whole machine is light in weight, which is convenient for operators to hold and move easily. Whether it is short-distance transportation of materials in the warehouse or precise loading of equipment in the workshop, it can be flexibly responded.

Vehicle-mounted flexible screw conveyor: cleverly combines conveying equipment with vehicles and has excellent mobility. It can be easily mounted on various pickup trucks, trucks and other vehicles. As the vehicle drives to different work sites, it can quickly put into material transportation without complicated installation and disassembly processes. Whether it is loading, unloading and transporting grain in rural areas, or on-site transportation of cement, sand and gravel and other building materials at construction sites, it can quickly reach the work site, greatly improving work efficiency and mobility.

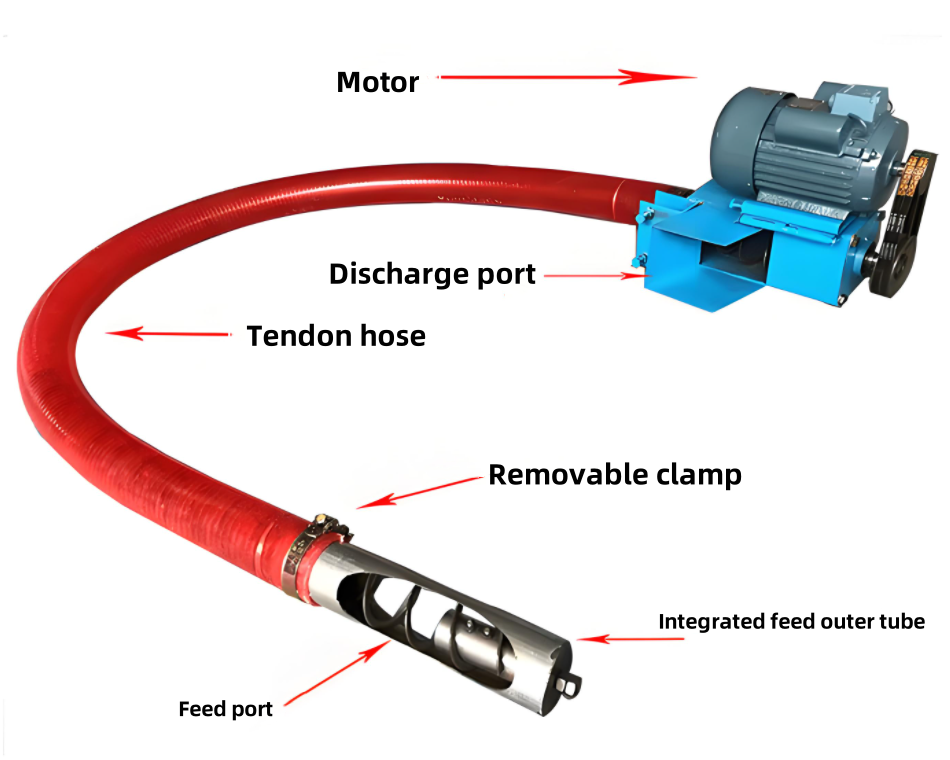

The structure of Flexible Screw Conveyors is relatively simple, but each component is very important.

Flexible spiral blade: This is the key component that distinguishes the flexible screw conveyor from the traditional rigid screw conveyor. Its special elastic material and spiral structure design enable it to flexibly adapt to various complex paths during transportation, and the damage to the material is minimal.

Tendon hose: tightly wrapped around the outside of the spiral blade, it plays a dual role of protecting and guiding material transportation. The conveying pipe has good flexibility and wear resistance, and can withstand the friction and impact of the material during transportation.

Drive system: usually composed of an energy-efficient motor and a precision reducer. The power and speed of the drive system can be precisely adjusted according to the actual conveying needs to ensure that the spiral blades rotate at the appropriate speed.

The core principle of the flexible screw conveyor is to push the material forward by the rotation of the spiral blades. When the motor drives the screw shaft to rotate, the spiral blades push the material from the feed port to the discharge port. Its design allows the material to be evenly accelerated during the conveying process, reducing the wear and damage of the material. Due to the characteristics of the flexible spiral, the equipment can be transported in multiple directions in a smaller space, effectively coping with complex production layouts.

The flexible screw conveyor has the following performance advantages due to its unique combination design of shaftless spiral and wear-resistant hose.

Unparalleled installation flexibility: This is its most prominent advantage. Since both the outer tube and the inner spiral can be bent, the conveying line can easily bypass existing equipment, columns, corners and other obstacles to achieve horizontal, inclined (any angle) or even vertical material lifting.

Fully enclosed conveying, clean and environmentally friendly: The entire conveying process is carried out in a closed pipeline, which effectively prevents dust leakage and meets the high requirements of the food, pharmaceutical and other industries for a sanitary environment.

Simple structure and convenient maintenance: Compared with complex conveying systems, the moving parts of flexible screw conveyors are only spiral springs and drive devices, and the structure is relatively simple, which greatly shortens the maintenance downtime.

Wide range of applicable materials: It can effectively convey most free-flowing or semi-free-flowing powders, granules, small balls, and flakes, such as flour, sugar, salt, plastic particles, coffee beans, seeds, and certain chemical powders.

Relatively gentle conveying: Compared with some high-speed pneumatic conveying, the impact and shear force of materials in flexible screws are relatively small, which is more friendly to some slightly fragile materials.

Cost-effectiveness: In the application scenarios of medium and short distances and small and medium conveying volumes, flexible screw conveyors usually provide a competitive investment and operating cost solution.

Flexible Screw Conveyors are widely used in different types of materials, mainly including the following.

Powdered materials: For powdered materials such as flour, cement, and chemical raw material powder, since powdered materials have good fluidity but are prone to dust, the closed conveying method of the flexible screw conveyor can effectively prevent dust from spilling out.

Granular materials: Granular materials such as grains, feed pellets, plastic particles, and sand, the rotation of the spiral blades can evenly push the particles forward, and the wear on the particles during the conveying process is minimal, which can well maintain the original shape and quality of the materials.

Irregularly shaped materials: Some irregularly shaped materials, such as crushed ore, waste electronic components, etc., can also be conveyed by flexible screw conveyors. Its flexible conveying structure can adapt to the irregular shape of the material and ensure that the material passes smoothly through the conveying pipeline.

|

Hierarchy |

Material |

Function |

|

Inner Lining |

UHMWPE |

Coefficient of friction < 0.15 |

|

Reinforcement Layer |

Kevlar Fiber |

Tensile strength > 200MPa |

|

Outer Protection |

Polyurethane |

Weather resistance: -40℃~120℃ |

Our customers are used in different industries. The following are some customer feedback.

Flour conveying in food factories: A large flour processing factory originally used manual bagging, which caused serious dust pollution and low efficiency. Three food-grade flexible screw conveyors were purchased, and the efficiency was increased to 8 tons/hour.

Closed transportation of titanium dioxide in chemical plants: Chemical plants need to convey titanium dioxide from vehicles to storage bins. Traditional pneumatic conveying consumes a lot of energy and causes serious material adhesion. Explosion-proof flexible screw conveyors reduce energy consumption by 40% compared with pneumatic conveying, and the material residue is <0.1%.

Raw material conveying in feed factories: Soybean meal and corn flour need to be conveyed from warehouses to carriages. The original forklift was inefficient and polluting. A vehicle-mounted flexible screw conveyor was installed, powered by diesel, with a conveying capacity of 20 tons/hour (5 times higher than the original method).

The price range of flexible screw conveyors is 80.00-80.00−1000.00/Set, and the specific price depends on the equipment specifications, material configuration and functional requirements. The basic small machine (conveying capacity 0.5-2m³/h) uses carbon steel spiral and PVC hose, which is suitable for ordinary powder conveying; the mid-range model (300-300−600) is equipped with 304 stainless steel spiral and wear-resistant PU hose to meet food grade requirements; the high-end customized model (800-800−1000+) uses 316L stainless steel and explosion-proof design, which is suitable for harsh environments such as pharmaceuticals and chemicals. The price difference is mainly reflected in the motor power (0.5-5.5kW), hose length (1-10m) and intelligent control system (such as variable frequency speed regulation, material blocking alarm). We provide standard models with optimized cost performance, and support special customization such as anti-static and high temperature resistance. All equipment has passed CE certification and enjoys a 1-year warranty.

Flexible screw conveyor, with its unique flexible conveying mode and excellent performance advantages, provides a high-speed, flexible and reliable solution for material conveying in industrial production. In the context of increasing production efficiency and environmental protection requirements in various industries, flexible screw conveyors will surely play a more important role in future industrial production and help various industries achieve sustainable development.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!