Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

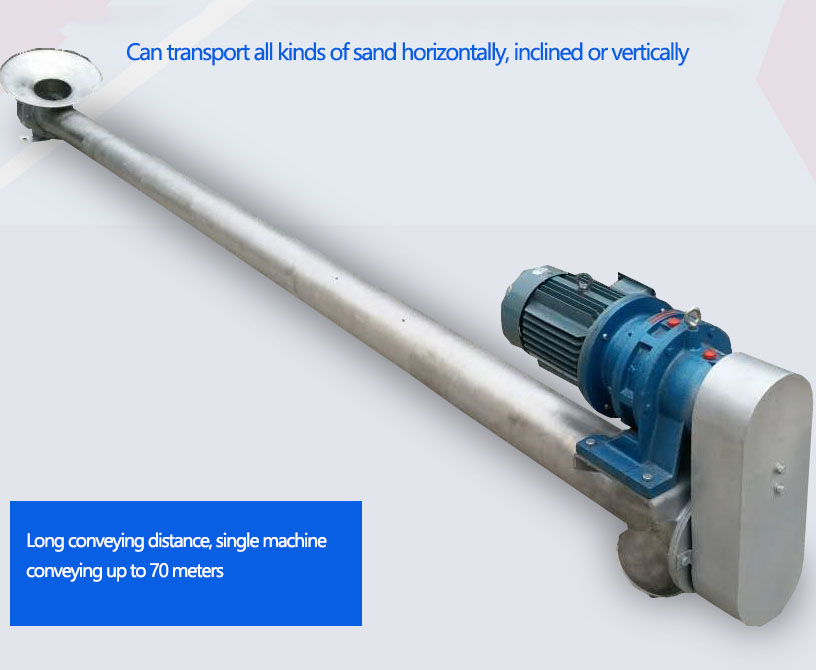

Specially designed for sand conveying, it can convey fine sand horizontally, inclined or vertically

Price: $400.00-$18,000.00/Set Chat Now

Delivery capacity: 143 cubic meters per hour

Conveying distance: 60-70 meters (length can be extended design)

Application: river sand, fine sand, silt, white sand, cement, etc.

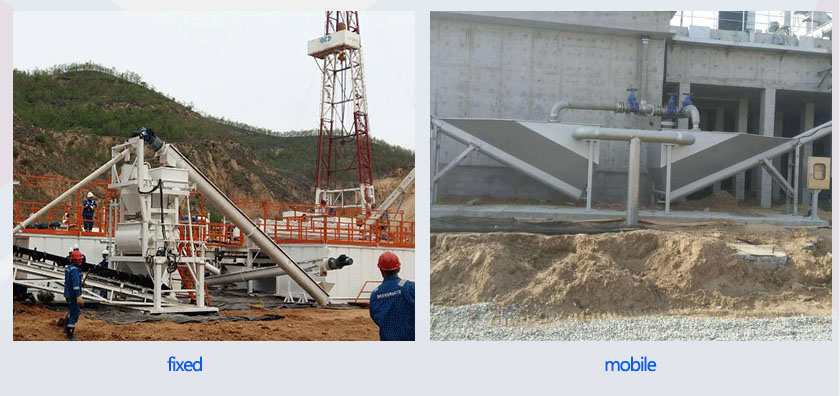

Sand Screw Conveyor is a device for conveying non-sticky dry powdery and granular materials such as sand. It can be conveyed horizontally, inclined or vertically. Sand Screw Conveyor can be divided into two types: fixed type and mobile type according to the installation method. According to the direction of conveying Or the speed is divided into two types: horizontal slow speed and vertical fast speed. In the actual conveying process, the horizontal slow speed screw conveyor is more commonly used.

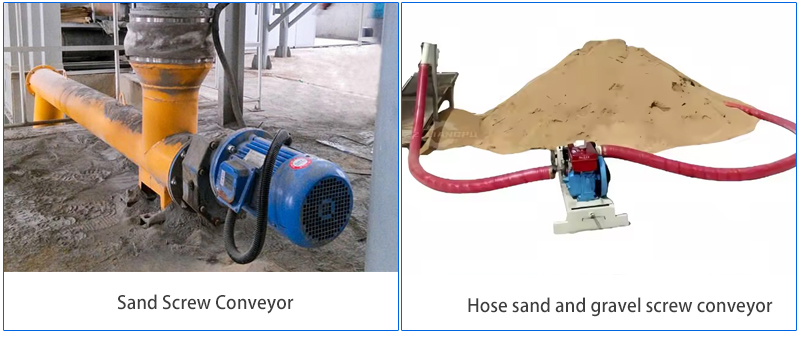

These two types of screw conveyors are suitable for efficient sand transportation in different situations. Here are some brief introductions:

Sand Screw Conveyor: It uses spiral blades to move materials along the axis of the conveyor, thereby achieving material transportation and processing. It is usually used in construction sites, mines, concrete mixing plants and other occasions to transport granular materials such as sand, gravel, cement, etc.

Hose sand and gravel screw conveyor: Hose sand and gravel screw conveyor combines the characteristics of hose conveying and screw conveying. It can bend and adapt to complex conveying paths and is suitable for occasions that require curved conveying. It can convey a variety of granular materials, including sand and gravel, granular fertilizers, grains, etc.

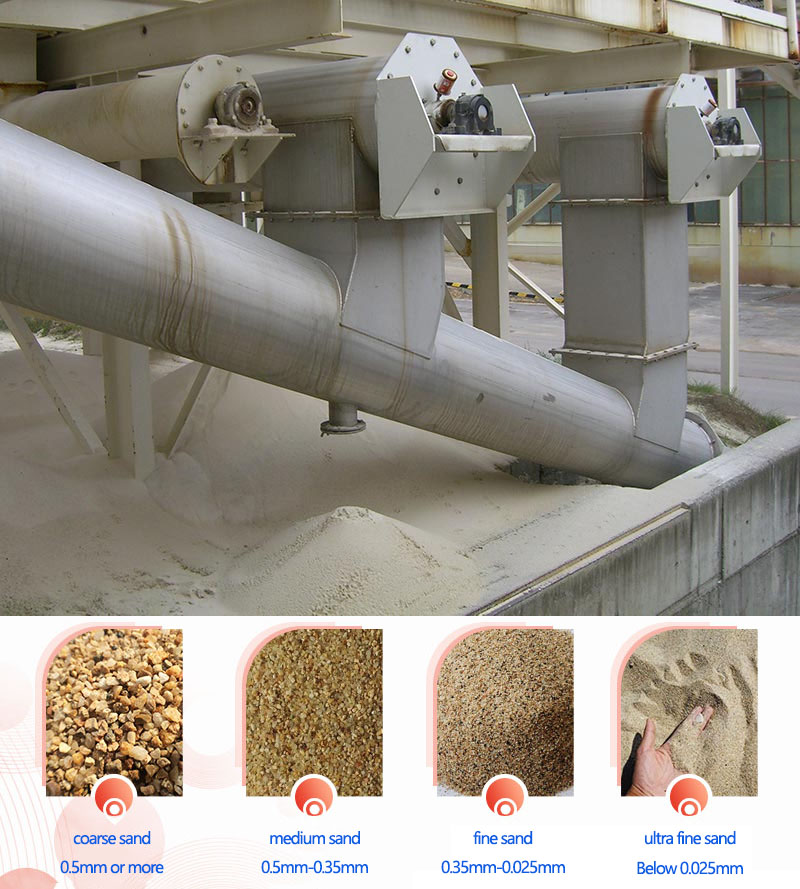

Sand Screw Conveyor can be used for conveying all kinds of sand, such as: sea sand, mountain sand, river sand, ultra-fine sand, fine sand, medium sand, coarse sand, machine-made sand, etc.

Stone and gravel: used in construction, road construction and infrastructure projects.

Sand: used in concrete, glass manufacturing, construction and other engineering projects.

Ores: including metal ores, coal ores, etc., used in mining and metallurgical industries.

Waste materials: such as the processing and transportation of waste bricks, scrap metals, etc.

1. The conveying distance is long, and the conveying distance of a single machine can reach 60-70 meters;

2. The fully enclosed structure design can ensure that the conveyed materials are not polluted;

3. There is a cleaning device at the discharge end, which can reduce material blockage;

4. The shell is made of seamless steel pipe, and the ends are connected with each other by flanges, which has good rigidity;

5. It can be arranged at different angles according to user requirements.

The Sand Screw Conveyor is mainly driven by the motor to rotate the screw. When the screw shaft rotates, due to the gravity of the material and the friction with the tank wall, the material can only move forward along the bottom of the conveyor under the push of the blade. Move to realize the conveying of materials.

| Model | Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

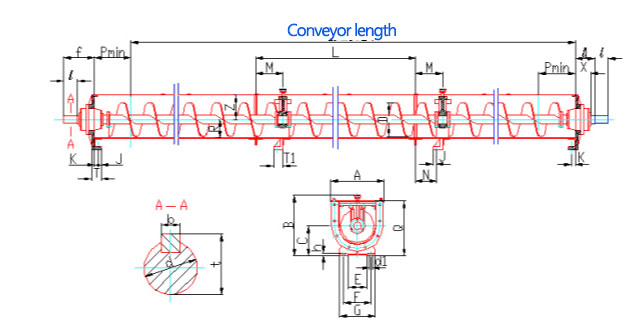

Sand Screw Conveyor is mainly composed of head bearing, tail bearing, driving device, screw, casing, cover plate and base. The driving device is composed of motor, reducer, coupling and other components.

Head bearing: The head bearing supports the head of the screw shaft of the screw conveyor, ensuring the stable operation of the screw shaft.

Tail bearing: The tail bearing supports the tail of the screw shaft of the screw conveyor, which helps to reduce axial movement and maintain the smooth operation of the conveyor.

Drive device: The drive device provides power for the conveyor, usually composed of components such as motors, reducers, couplings, etc., drives the screw shaft to rotate and promotes the conveying of materials.

Spiral blade: The spiral blade is the core component of the screw conveyor, responsible for transporting the material along the axis of the conveyor.

Casing: The casing is the outer shell of the screw conveyor, providing a space to contain the spiral blades and materials, ensuring that the materials do not overflow during the conveying process.

Cover: The cover covers the top of the casing to prevent dust and protect the internal components.

Base: The base supports the entire conveyor, fixed to the ground, and maintains the stability of the conveyor.

Sand Screw Conveyor Dimensions, including its length, width, and height, must be tailored to the specific needs of your operation to ensure the right size is selected for efficient abrasive conveying and handling.

1. Length and Width: The length and width of the conveyor belt should be determined based on the size and quantity of abrasive being transported. For large quantities of abrasive, wider and longer conveyor belts are required to ensure efficient transport and reduce spillage and accumulation. The length and width selection should take into account the flowability and conveying speed of the abrasive.

2. Height: The height of the conveyor needs to match the existing equipment and workflow to ensure smooth material flow. Adjustable height options can provide flexibility so that the conveyor can be integrated with different systems. The height selection should also consider the drop of the abrasive and the final unloading position.

3. Material Characteristics: In addition to size, material characteristics such as density, particle size, and moisture content of the abrasive should also be considered. These characteristics will affect the design and size selection of the conveyor.

4. Environmental Factors: Consider the environment in which the conveyor will be installed, such as unrestricted space, ambient environmental conditions, etc., to ensure the selected size can operate effectively and meet safety standards.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!