Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

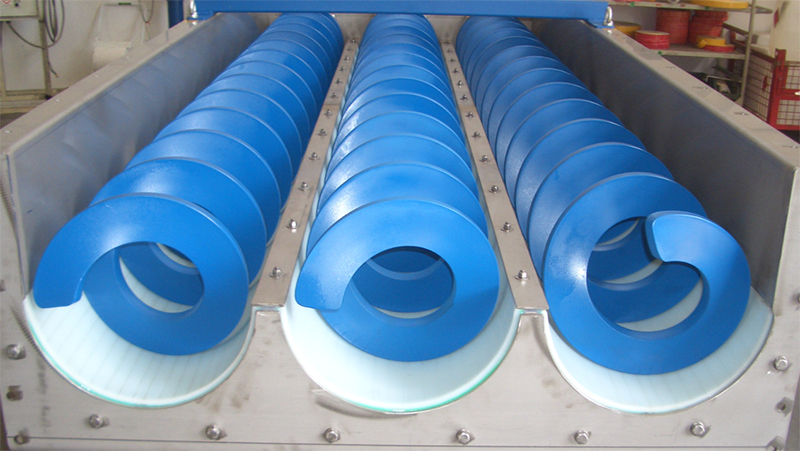

Shaftless Screw Conveyor for Sludge is a device specially used for conveying sludge and similar materials. The design without center shaft abandons the center shaft of the traditional shaft screw conveyor, so that the screw body will not have the problem of material winding around the shaft when conveying materials. It is especially suitable for sludge, which is sticky, fibrous and may contain impurities.

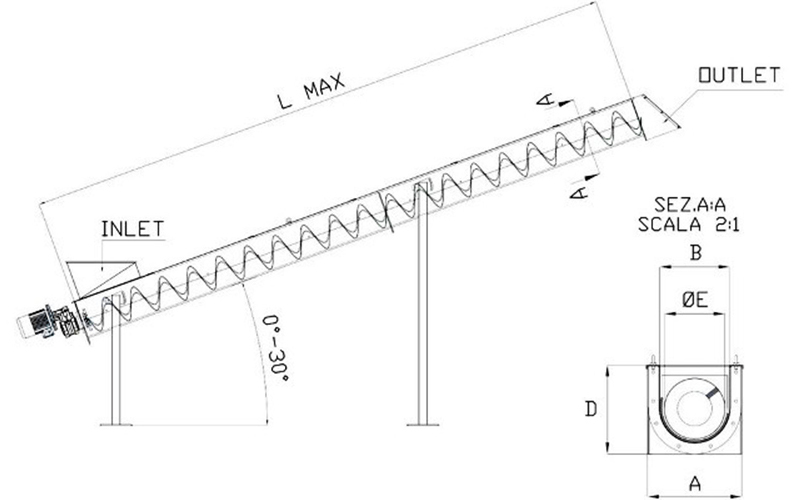

The Shaftless Screw Conveyor for Sludge is designed for conveying sludge in sewage treatment plants and industrial applications. It features a center-shaftless structure with strong anti-entanglement properties. Customizable in carbon steel, 304/316L stainless steel, and other materials, it is resistant to acid and alkali corrosion. Its non-standard design allows for horizontal, inclined, and multi-angle conveying. The maximum length of a single unit is 3 meters, with a conveying capacity of 458 m³/h. It also features variable frequency speed regulation and a fully enclosed, leak-proof structure.

"Dahan" Shaftless Screw Conveyor is specially designed to solve the problem of sludge winding for you, and at the same time reduce the problem of sludge damage during the conveying process, saving manpower and material resources while saving energy.

Shaftless Screw Conveyor for Sludge is a device used to transport sludge, waste and solid particles. When choosing a Shaftless Screw Conveyor, factors such as the water content of the sludge, the conveying distance and the conveying volume need to be considered. The following is the model, length and conveying capacity of the shaftless screw conveyor used for sludge with different water content:

For sludge with a water content of 20%, use a WLS160 shaftless screw conveyor with a length of 10 meters and a conveying capacity of 1.2 cubic meters per hour.

For sludge with a water content of 40%, use a WLS200 shaftless screw conveyor with a length of 15 meters and a conveying capacity of 1.5 cubic meters per hour.

For sludge with a water content of 60%, use a WLS250 shaftless screw conveyor with a length of 20 meters and a conveying capacity of 2.0 cubic meters per hour.

Shaftless Screw Conveyors for Sludge conveying equipment for sludge, waste, and solid particles require close consideration of key parameters such as sludge moisture content, conveying distance, and processing capacity. The WLS160-250 series, through optimized screw diameter and length design, precisely matches conveying capacity requirements of 1.2-2.0 m³/h, ensuring stable operation of the treatment process, covering diverse operating conditions with a moisture content ranging from 20% to 60%.

The shaftless screw conveyor for sludge effectively avoids entanglement and jamming of highly viscous sludge. The 304/316L stainless steel material is highly corrosion-resistant, and the fully enclosed structure prevents leakage and pollution.

Shaftless Screw Conveyor - Solve the problem of sludge entanglement!

According to the nature of the sludge, Dahan recommends that you choose the Shaftless Screw Conveyor, and use the advantages of the Shaftless Screw Conveyor's anti-winding and anti-stickiness to solve the problem of difficult transport of sludge. Compared with traditional conveyors, Shaftless Screw Conveyor can convey granular and powdery materials, wet and pasty materials, semi-fluid and viscous materials, easily entangled and clogged materials, and materials with special hygienic requirements.

Shaftless Screw Conveyor - Reduce sludge pollution problems!

Shaftless Screw Conveyor has compact structure, saves space, is easy to operate, economical and durable, and has good performance. The use of a fully enclosed and easy-to-clean spiral surface can ensure that the conveyed materials will not be polluted and will not leak conveyed materials. It can reduce the damage problem of sludge during transportation.

Shaftless Screw Conveyor - Simple operation saves manpower and material resources!

The conveying capacity of the Shaftless Screw Conveyor is 1.5 times that of the shaft screw conveyor with the same diameter. The conveying distance is long, and the conveying length of a single machine can reach 60~70m. Large torque, low energy consumption, and no blockage of the discharge port. Its automated operation also greatly saves manpower and material resources.

The Shaftless Screw Conveyor for Sludge, with its center-shaftless design, enables stable conveying of materials such as sludge, biomass fuel, filter residue, pulp, food waste, and lightweight particles. It is particularly suitable for complex working conditions involving high viscosity, easy clogging, or long fibers.

Urban domestic sludge: In urban sewage treatment plants, shaftless screw conveyors can effectively convey it to subsequent treatment equipment.

Industrial sludge: Sludge produced in industrial production processes such as chemical, electroplating, and papermaking. Shaftless screw conveyors can adapt to these industrial sludges with different characteristics and transport them from the production link to the treatment or disposal site.

Wine lees: Wine lees produced in the winemaking process have a certain humidity and viscosity. Shaftless screw conveyors can transport wine lees from the brewing workshop to storage or reuse sites.

Methane residue: In biogas projects, sludge is the product of anaerobic fermentation. Shaftless screw conveyors can transport sludge from biogas tanks to subsequent treatment units.

Wet construction waste: If the construction waste contains a certain amount of moisture, the shaftless screw conveyor can transport it to a designated location for classification or recycling.

Food processing waste: Waste generated in the food processing process usually has a high humidity and a certain viscosity. Shaftless screw conveyors are able to transport this waste material to a processing facility.

The sludge shaftless screw conveyor drives the spiral blades without center shaft to rotate in the closed tank body through the motor, and uses the continuous pushing action of the spiral blades to move the material along the axial direction of the tank body. The integral belt-shaped spiral blades are used to form a continuous propulsion surface when rotating, which effectively solves the entanglement and blockage problem of high-viscosity sludge and fiber-containing impurity materials. During operation, the material falls into the bottom of the tank body from the feed port, and is pushed forward under the action of the axial component force generated by the rotation of the blades. At the same time, the matching gap between the blades and the tank wall can prevent the material from flowing back, and finally discharged from the discharge port.

The Shaftless Screw Conveyor for Sludge, with its center-shaftless design, effectively avoids sludge entanglement and blockages that plague traditional shafted conveyors. It is particularly well-suited for conveying sludge with high viscosity, high moisture content, and impurities.

Municipal Wastewater Treatment: After the sludge thickening tank, it stably conveys viscous primary sludge and excess sludge with a moisture content of 90%-95% to the dewatering machine, preventing clogging. After dewatering, it can also transfer sludge cake with a moisture content of 60%-80% to a temporary storage silo or subsequent processing equipment.

Industrial Wastewater Treatment: This equipment is suitable for various industrial specialty sludges, especially those containing impurities and corrosive substances. In the chemical and printing and dyeing industries, stainless steel is used to withstand corrosion from sludge containing acids, alkalis, and dyes, preventing equipment damage. In the food and pharmaceutical industries, food-grade materials are available to meet hygiene standards. River and Municipal Dredging Projects: This equipment offers significant advantages for handling high-water content wet sludge generated during river and pipeline dredging. During river dredging, it can transport sediment containing sand, gravel, and aquatic plants to processing equipment. Its shaftless design prevents clogging due to impurities. During municipal pipeline dredging, it can flexibly adjust its angle in confined spaces.

Waste Management and Solid Waste Disposal: This equipment can adapt to various sludge transport needs throughout the waste management chain. In landfills, it can transfer leachate sludge after leachate treatment to landfills or drying plants.

Agriculture and Livestock Farming: In large-scale farms, it can transport manure sludge after solid-liquid separation to fermentation tanks or organic fertilizer equipment, eliminating clumping and entanglement issues.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

For sludge transportation, choose Dahan shaftless screw conveyor, which has fast sludge transportation, large output, and no winding!

As the source manufacturer of Shaftless Screw Conveyor for Sludge, we provide customers with different types and models of conveying equipment, which can be tailored to customers' site and production needs.

Conveying sedimentation tank sludge: angle 40 degrees, length 8 meters, 20 cubic meters per hour;

Conveying sludge: 4-5 tons per hour, 10.04 meters high, 20 meters long, 70° angle, and a shaftless screw conveyor with a large inclination of 325mm;

Oily sludge is stored in the conveying tank: the moisture content is 60%-80%, and the sludge is stored in the tank, and the shaftless screw conveyor with a large inclination angle;

Sludge conveying from sewage plant: inclination angle 30 degrees, conveying length 25m, conveying 3 tons per hour;

The specific gravity of the dried sludge after conveying is 0.6-0.8g/cubic centimeter, the dump truck feeds 4 liters, and the vibrating feeder discharges the material to the shaftless screw conveyor, with a conveying capacity of 5 tons per hour;

304 stainless steel shaftless screw conveyor, sludge 3 meters (its drying equipment is high), feeding 300 kg per hour, silo 300-500 kg;

Sludge conveying from water plants: The height of the inlet and outlet is 4.0 meters, 5m³ per hour, and a vertical shaftless screw conveyor is required;

The maximum inclination angle of the sludge shaftless screw conveyor depends on the material characteristics, equipment design and screw type.

Shaftless screw conveyor: recommended angle ≤15° (suitable for viscous and entangled sludge; limit angle ≤25° (needs to be matched with high viscosity materials or special blade design).

Key factors affecting the inclination angle

Sludge with high water content (>85%): the inclination angle is recommended to be ≤15°, otherwise it is easy to drip or backflow.

Dehydrated mud cake (water content 60-80%): 20-25° can be tried, which needs to be verified by experiment.

Sludge with high viscosity or fiber: the inclination angle needs to be further reduced (such as ≤10°).

Practical application suggestions: Prioritize horizontal or low inclination installation (<15°) to ensure stable conveying efficiency. If a large inclination angle (>30°) is required, use a bucket elevator or spiral tube conveyor.

Compared with the shafted screw conveyor, the shaftless screw conveyor for sludge has the following advantages in conveying sludge.

Not easy to block: The shaftless screw conveyor has no central shaft, and the spiral body is a continuous blade as a whole. The material will not be entangled on the shaft during the conveying process, nor will it be easy to accumulate at the connection between the shaft and the blade. The central shaft of the shafted screw conveyor is easily entangled by fibers, debris, etc. in the sludge, affecting the conveying efficiency.

High conveying efficiency: The spiral blades of the shaftless screw conveyor are usually wider, and there is no obstruction of the central shaft. The material has a larger circulation space during the conveying process and can accommodate more sludge.

Good sealing: The shaftless screw conveyor usually adopts a fully enclosed shell, which can effectively prevent the sludge from leaking during the conveying process and reduce the pollution to the environment. Especially for some sludge containing harmful substances. The shafted screw conveyor may have a poor sealing problem at the connection between the shaft and the shell, which is prone to sludge leakage.

Low maintenance cost: Since the shaftless screw conveyor has no vulnerable parts such as the center shaft and bearings, the frequency of replacement due to wear of these parts is reduced, and the maintenance workload and cost are reduced. The center shaft, bearings and other parts of the shafted screw conveyor are easily damaged due to long-term wear of sludge.

Strong adaptability: The shaftless screw conveyor can be designed into different shapes and lengths according to different conveying requirements and site conditions, and has strong adaptability.

The price of sludge shaftless screw conveyor varies depending on the manufacturer, specification, material, conveying capacity and other customized requirements. If the material requirement is upgraded to stainless steel, or a larger conveying capacity, longer conveying distance and other customization are required, the price will increase significantly. The specific price will be combined with your specific needs to give you a detailed quotation sheet. If you need it, please feel free to send us a message!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!