Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Cement Screw Conveyor is a kind of material conveying equipment used in cement production line. It adopts the principle of spiral rotation to convey cement or similar materials from one place to another in a continuous, stable and efficient manner. In the cement production process, the Cement Screw Conveyor is an essential equipment, it can transport the cement from the mill to the packaging line, it has the advantages of large transmission capacity, simple maintenance and convenient operation.

Conveying Dry Cement Powder

Conveying Wet Cement

Cement Screw Conveyor is mainly used for the continuous conveying of materials in the cement production line, such as conveying cement from the mill to the packaging line, or conveying concrete mixing materials to the construction site, etc., and can also convey fly ash, gypsum and other materials, as well as mixed materials mixing and conveying. It has a wide range of applications and can be applied to many industries, such as construction, chemical industry, food, metallurgy, mining and other industries.

In the field of cement industry, Cement Screw Conveyor has a wide range of customer groups, such as China Resources Cement, Conch Cement, China National Building Materials and other large cement production enterprises, as well as some small and medium-sized cement processing enterprises. At the customer site, we can see that the Cement Screw Conveyor is widely used and has the advantages of large transmission capacity, convenient use, and small footprint. It can also be customized according to different needs to meet the special requirements of customers.

Conveying cement to cement tanks

Length: 18 meters

Delivery capacity: 7 tons/hour

400mm cement screw conveyor

Inclined 33-50° to convey cement

Length: 3.6 meters,the feeding port is 0.5 meters from the ground

Delivery capacity: 35-50 tons/hour

219mm tubular cement screw conveyor

Vertical conveying of dry cement powder

Length: 5 meters

Delivery capacity: 250 cubic meters/hour

400mm cement screw conveyor

Inclined at 25° to convey dry cement

Length: 4 meters

Delivery capacity: 35 tons/hour

200mm cement screw conveyor

A cement factory purchased a Cement Screw Conveyor for conveying cement and gypsum. Due to the compact structure and high conveying efficiency of the equipment, it can meet the conveying needs of a large amount of materials in cement plants. In addition, the installation and maintenance of the equipment are also very convenient, which greatly improves the production efficiency and the service life of the equipment.

1. High transmission efficiency: Cement Screw Conveyor adopts the principle of spiral rotation, which can maintain a continuous and stable material transmission speed within a certain range, effectively improving the transmission efficiency.

2. Long transmission distance: Cement Screw Conveyor is a kind of equipment that can transport materials. It has the advantage of long transmission distance, so it can meet the transportation requirements of long production lines.

3. Simple configuration: Cement Screw Conveyor is easy to maintain due to its simple structure and convenient use, which greatly reduces maintenance costs.

In a word, Cement Screw Conveyor is an indispensable equipment, which can effectively improve the working efficiency of cement production line, reduce labor and production costs, and is a very valuable investment.

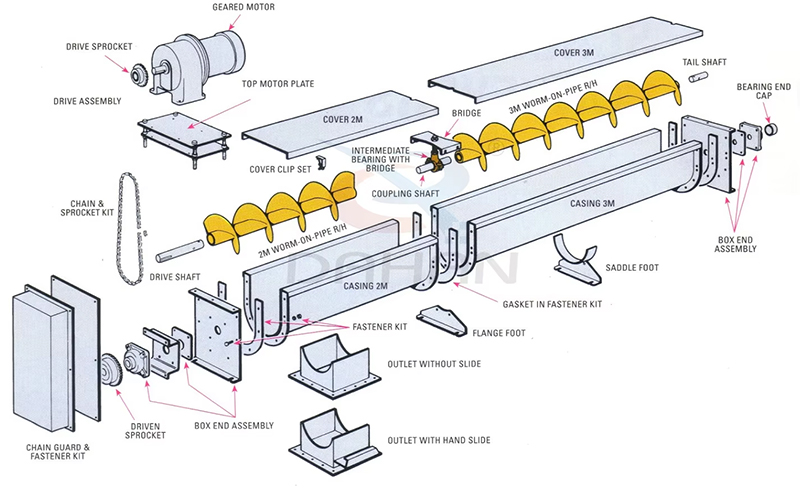

The cement screw conveyor has a simple and reliable structure and is suitable for conveying granular materials such as cement. It is usually composed of the following components:

Feed port: The entrance for loading cement or other materials into the conveyor.

Screw shaft: It is the core component of the conveyor. The screw shaft is fixed with spiral blades, which push the material forward by rotation.

Screw blades: Fixed on the screw shaft, responsible for pushing the material from the feed port to the discharge port.

Bearings and seals: Used to support and protect the screw shaft, reduce friction loss, and ensure the stable operation of the conveyor.

Discharge port: The outlet that releases the conveyed cement or material to the target location.

| Model |

Spiral diameter (mm) |

Screw-pitch (mm) |

Speed (r/min) |

Capacity (m³/h) |

| LS-100 | 100 | 100 | 140 | 2.2 |

| LS-160 | 160 | 160 | 112 | 7 |

| LS-200 | 200 | 200 | 100 | 13 |

| LS-250 | 250 | 250 | 90 | 22 |

| LS-315 | 315 | 315 | 80 | 31 |

| LS-100 | 100 | 355 | 71 | 56 |

| LS-500 | 500 | 400 | 63 | 98 |

| LS-630 | 630 | 450 | 50 | 140 |

| LS-800 | 800 | 500 | 40 | 300 |

| LS-1000 | 1000 | 560 | 32 | 280 |

| LS-1250 | 1250 | 630 | 25 | 380 |

The cement screw conveyor realizes the material conveying process through the rotation of the spiral blade. When the material is loaded into the conveyor from the feed port, the subsequent rotation of the screw shaft pushes the spiral blade to convey the material to the discharge port. During the conveying process, the spiral blade rotates continuously, clamping the material and pushing it forward, forming a continuous conveying flow. Finally, the material reaches the discharge port, and the spiral blade pushes it out to complete the conveying task.

Dahan Cement Screw Conveyor focuses on product quality and customer satisfaction, and is always committed to providing customers with reliable products and high-quality services. Whether it is a standard model or a customized design, it can meet the different needs of customers. Our products undergo strict quality control and testing to ensure stable and reliable operation in various working environments. There are screw conveyors of different materials and different models, as well as shaftless and shafted spiral blades. As a source manufacturer, we can serve you more conveniently and recommend the most suitable conveying equipment for you based on your situation!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!