Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

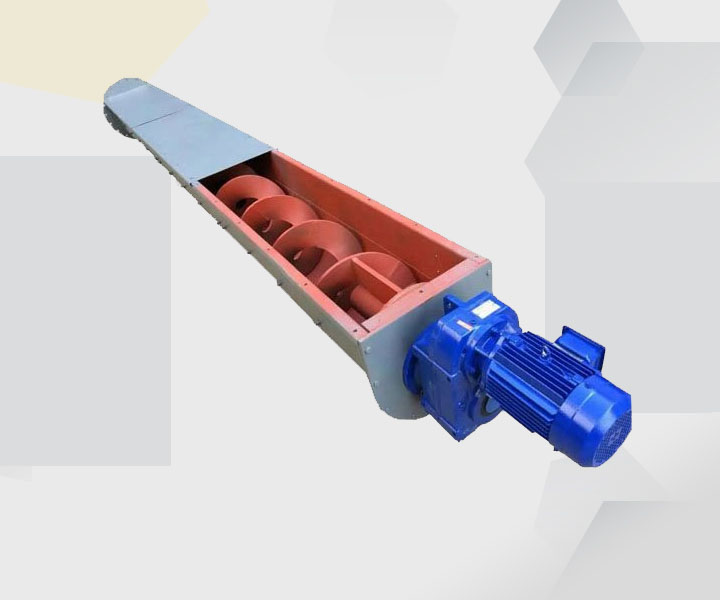

Special equipment for sludge transportation in sewage treatment plants, strong anti-winding, not easy to block materials, stainless steel material is corrosion-resistant, no material leakage, no odor overflow

Price: $560.00-$6,190.00 Chat Now

Delivery capacity: 458 cubic meters per hour

Conveying length: 60-70 meters

Diameter: 150 - 470 mm

Length: 0-20 mt or 0-30 mt

Capacity: from 0.8 mc/h to 45 mc/h

Inclination of installation: 0-20°

Material: Carbon steel or stainless steel

Application: The shaftless design is specially designed for handling sticky sludge, which can prevent the sludge from sticking and clogging during the transportation process.

Sludge Screw Conveyor is specially designed for transporting sludge, mud cake, sludge and other viscous and easily entangled materials. It adopts a shaftless design. Because there is no interference from the central shaft, the sludge is not easy to stick when transporting sludge. On the spiral blade, or agglomeration, the Sludge Screw Conveyor can also perform operations such as mixing, stirring, and cooling on the sludge during the conveying process, which can avoid the sludge agglomerating during the conveying process.

Note: Since the sludge material contains a large amount of corrosive materials, it is recommended that the sludge screw conveyor be made of stainless steel.

Sludge Screw Conveyor is specially used in sewage treatment plants to transport medium and fine screen decontamination machine slag and mud cake after sludge dehydration. The dehydrated sludge cake is transported to the sludge transport vehicle through the Sludge Screw Conveyor, and transported to the sludge landfill for landfill treatment.

Chemical industry: Various sludges generated during the chemical production process can be transported to special treatment equipment through sludge screw conveyors for harmless treatment or resource recycling.

Electroplating industry: Sludge screw conveyors can transport electroplating sludge from the electroplating workshop to the sludge treatment workshop. After a series of treatments, heavy metal recovery and harmless disposal of sludge can be achieved.

Landfill: In the landfill, sludge screw conveyors can be used to mix sludge generated by urban sewage treatment plants with garbage for landfill.

Waste incineration plant: For some cities that use waste incineration to generate electricity, sludge screw conveyors can transport sludge to waste incinerators for incineration.

Organic fertilizer production: Sludge screw conveyors can transport treated sludge to fertilizer production equipment, mix it with other raw materials, and produce organic fertilizer for agricultural production to improve soil fertility.

Municipal dewatered sludge transportation: Belt filter presses are used to dehydrate sludge to produce mud cakes with a moisture content of about 80%, which need to be transported to the sludge storage area for loading and transportation. Install a horizontal shaftless screw conveyor with a length of 15m. The shaftless design avoids sludge entanglement and can transport 5-8 tons of sludge per hour.

Closed transportation of chemical wastewater sludge: The wastewater treatment station produces oily sludge (corrosive), which needs to be transported from the concentration tank to the incinerator. Equipped with an inclined stainless steel shafted screw conveyor with a length of 10m and an explosion-proof motor.

River sludge transportation: The water content is 90%, and the sludge needs to be transported from the temporary sedimentation tank to the dewatering equipment. Install a movable screw conveyor with a length of 8m, and the spiral blades are equipped with an anti-stick coating to reduce sludge adhesion. The daily sludge processing capacity is 200m³.

Paper mill sludge recycling: The fiber sludge after wastewater treatment in the paper mill needs to be transported to the mixing bin and mixed with the raw materials for recycling. A horizontal U-shaped screw conveyor made of carbon steel is used, with a total length of 12m and a height of 3m at the end of the vertical lifting section, which saves space.

1. No central axis, strong anti-winding

Sludge contains a lot of impurities and has poor fluidity. The Sludge Screw Conveyor adopts a design without a central shaft, and uses a flexible integral steel screw to push the sludge. It has strong anti-winding performance and will not cause material clogging.

2. Fully enclosed structure, no smell, no pollution

Sludge has high water content and is polluting. It is easy to produce leachate, and the smell will overflow. The fully enclosed and easy-to-clean spiral surface is used to reduce environmental pollution.

3. Large conveying capacity

Sludge is mainly used in large-scale sewage treatment plants and other industries, which have certain requirements on the conveying capacity. The conveying length of a single conveyor can reach 60 meters. Due to the use of shaftless, the conveying capacity can be increased to a certain extent. Generally, it is an ordinary screw 1.5 times that of the conveyor.

4. Flexible layout

Sludge Screw Conveyor adopts "U" shape structure, middle loading and unloading, convenient maintenance, the conveying direction can be reversed, and can also be conveyed in two opposite directions at the same time, and the materials can be stirred, mixed, heated and cooled during the conveying process Wait for homework.

The Sludge Screw Conveyor drives the cycloidal reducer to run through the motor, and the screw rotates through the transmission of the mechanical seal shaft and the shaftless screw body. When the sludge is discharged into the upper part of the U-shaped groove, it passes through the screw. The transmission enables the sludge to be discharged from the discharge port at the bottom of the U-shaped groove to complete the conveying of materials.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

1. Material: Sludge contains a lot of impurities, and some sludge may have high pollution. Therefore, Sludge Screw Conveyor is generally made of 304 stainless steel, which is corrosion-resistant and easy to clean.

2. Thickness requirements: The sludge is viscous, so there are certain requirements for the thickness of the material. Generally, the blades of the screw conveyor are required to be made of high-strength materials with sufficient strength and rigidity. The thickness is not less than 20mm, and the height of the spiral blades is not less than 80mm.

3. The conveyor is equipped with overload protection and alarm to prevent a certain degree of damage to the machine caused by the large amount of sludge conveyed.

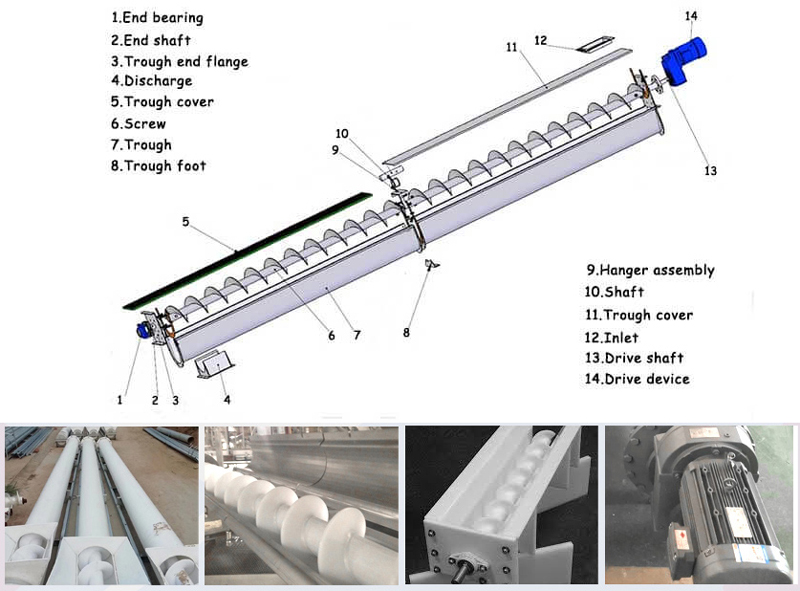

Sludge screw conveyor is mainly composed of the following core components.

Spiral blade: the core component that pushes the material forward, a strip blade without a central axis, suitable for viscous and entangled sludge (such as dehydrated sludge).

Trough: U-shaped trough is open or covered to prevent dust and splash, easy to maintain, with carbon steel, stainless steel (304/316, corrosion-resistant), wear-resistant lining.

Drive device: usually a reduction motor, three-phase asynchronous motor + reducer, frequency conversion control can adjust the speed to adapt to different conveying volumes.

Feed inlet: opening on the top or side, can be connected to the flange or soft connection sludge dewatering machine discharge port.

Discharge port: end or bottom design, can be equipped with a gate valve to control discharge.

When selecting a sludge conveyor, factors such as sludge characteristics, conveying volume, distance, site conditions and environmental protection requirements need to be considered comprehensively.

Sludge with high water content (water content > 85%, good fluidity): shaftless screw conveyor is recommended, which is anti-clogging and suitable for sludge containing fibers/impurities.

Dehydrated sludge (water content 60%~80%, semi-solid): shaftless screw conveyor is recommended, which is entangled, has good airtightness and is suitable for sticky mud cakes.

Oily/corrosive sludge: stainless steel screw conveyor is recommended, which is corrosion-resistant, has a long service life, accurately controls flow, and is suitable for high-risk materials.

Dry sludge particles (water content <50%): shafted screw conveyor is recommended, which has a simple structure and low cost.

Dahan Machinery Manufacturing Co., Ltd. is a professional manufacturer of sludge screw conveyors, dedicated to providing efficient and durable sludge conveying solutions for multiple industries. The company has more than 10 years of industry experience, integrating R&D, production, sales and service. Its products include shaft/shaftless screw conveyors, U-shaped/tube conveyors, customized sludge treatment equipment, etc. It is designed for high viscosity, high water content and corrosive sludge. The materials can be carbon steel, 304/316 stainless steel, wear-resistant lining, corrosion resistance, wear resistance, support variable frequency speed regulation, automatic control, conveying capacity 1-50t/h, inclination 0-30° (special design can reach vertical conveying). The length, angle, power, inlet and outlet position can be customized according to the working conditions, providing a one-stop solution.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!