Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

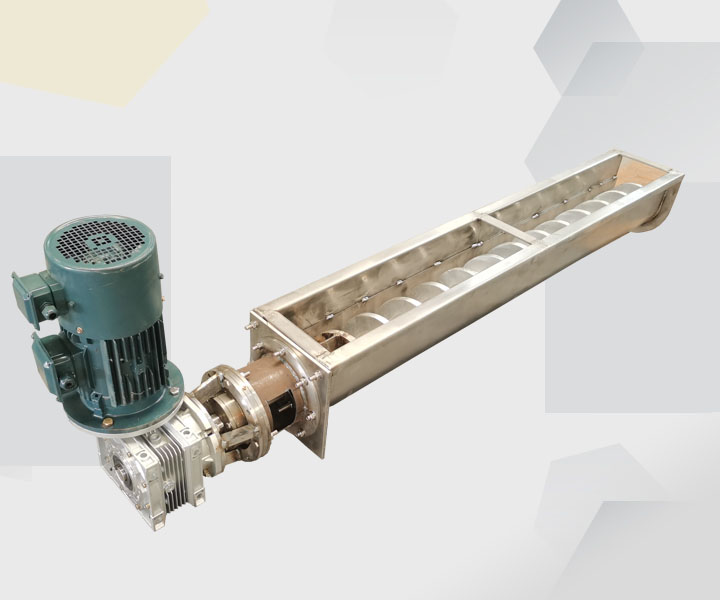

It is specially used for sludge, sewage and mud transportation, the shaftless design is anti-clogging, the stainless steel material is corrosion-resistant, and the fully sealed structure can avoid sludge leakage.

Price: $600.00-$3,560.00/Set Chat Now

Diameter: 150mm-500mm

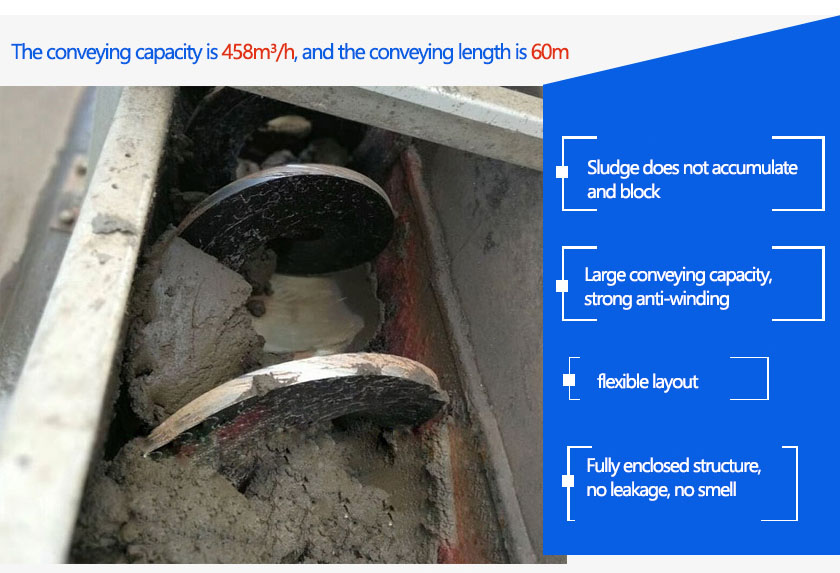

Delivery capacity: 458 cubic meters per hour

Conveying length: 60-70 meters

Power: 0.55kW-5.5kW

Torque: 4000N/m

Speed: 29rpm

Material: 304 stainless steel

Choice type: single shaftless, double shaftless

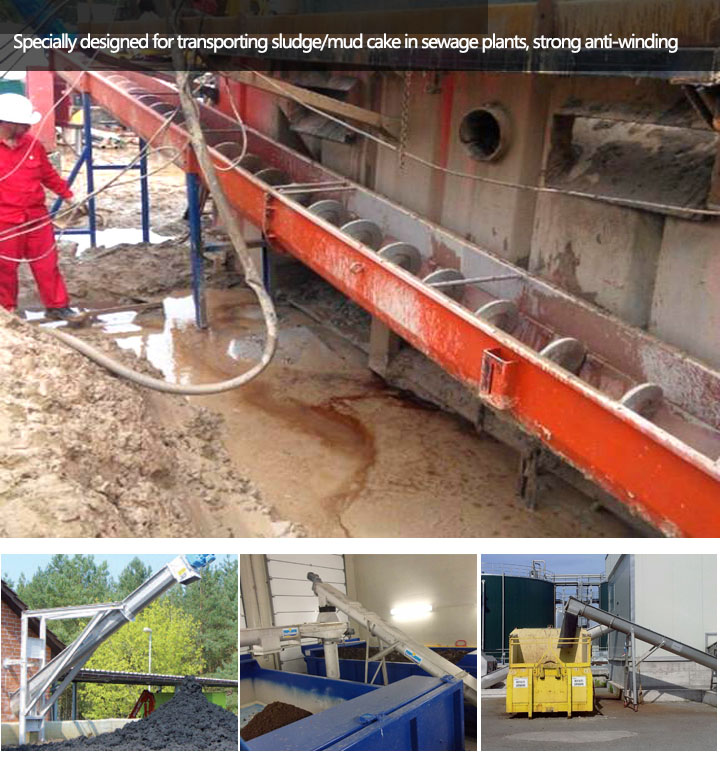

Used for sewage treatment plants, sedimentation tanks of waterworks, sludge, silt, and mud cake transportation of industrial wastewater plantss

The Sludge Shaftless Screw Conveyor, referred to as the Sludge Screw Conveyor, is used for the treatment and conveyance of dewatered sludge, sludge from municipal sewage treatment processes, residential sewage pretreatment plants or livestock waste applications such as manure handling systems, and since there is no intermediate bearing, it provides Creates a non-clogging conveying surface, eliminates sludge and slurry buildup, and ensures hassle-free material handling. Fully enclosed to prevent any material from escaping, tank lids with proper gaskets allow for odor-free operation and create a barrier to prevent any atmospheric media from entering the system.

Inclined conveying sedimentation tank sludge

Horizontal conveying of dried sludge

Conveying sewage plant sludge

Sludge Shaftless Screw Conveyor is specially used for the transportation of sludge, mud cake, silt and mud in sewage treatment plants, tap water sedimentation tanks, urban water supply plants, industrial wastewater treatment, etc.; it can transport materials with such density as sludge from one place to another place.

Sewage treatment plant: used to transport sludge from sedimentation tanks or sedimentation equipment to sludge treatment equipment, and transport sludge from sludge treatment equipment to sludge storage areas or to incineration equipment.

Sedimentation tank: used to transport precipitated mud cake or sludge from sedimentation tanks to sludge treatment equipment or treatment sites.

Water supply plant: used to transport mud or mud cake generated during the treatment process to sludge treatment equipment or storage areas.

Industrial wastewater treatment: used to transport sludge generated during industrial wastewater treatment to drying equipment, incineration equipment or other treatment equipment. Transport solid waste or sludge between industrial wastewater treatment equipment.

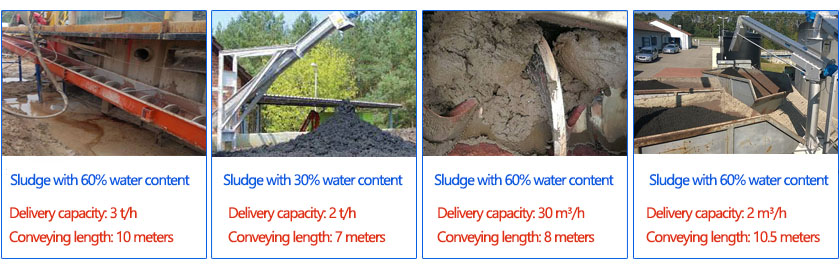

Sludge transport in sludge treatment plant: 6T a day, counted in 24 hours, screw length 2.5 meters, used as dryer, diameter 200mm

Sedimentation tank sludge transportation: the transportation angle is 40 degrees, the length is 8 meters, 20 cubic meters per hour, and the diameter is 400mm

Conveying dry dewatered sludge: moisture content 20%, conveying distance 8 meters, installed horizontally, conveying 5 tons of sludge per hour

Conveying dewatered sludge, 6 cubic meters per hour, inclined length 10 meters, angle 30 degrees

Horizontal conveying sludge: diameter: 260mm, conveying capacity: 2 t/h, N=1.5kW, L=3.5m

Conveying silt: diameter 200mm, length 9m, conveying capacity 3.5m³/h, inclination 25°, N=5.5KW

Wastewater plant transport sludge: distance 6.5 meters, height 3.5 meters, angle 30 degrees, motor power 7.5kw, 80 cubic meters per hour

1. Sludge does not accumulate and block: there are many impurities in the sludge and the fluidity is poor. The Sludge Shaftless Screw Conveyor is designed without a central shaft and uses a flexible integral steel screw to propel sludge. Strong anti-winding, will not cause material clogging.

2. Large transportation volume: sludge is mainly used in industries that have certain requirements for transportation capacity, such as large sewage treatment plants. The conveying length of a single conveyor can reach 60 meters, and the conveying capacity is 1.5 times that of ordinary screw conveyors.

3. No material leakage and no peculiar smell: the sludge has high water content, serious pollution, easy to produce leachate, and odor overflow, the tank cover of Sludge Shaftless Screw Conveyor with proper gasket can realize odorless operation and form a barrier to prevent any atmospheric medium Entering the system, it can ensure the sanitation of the environment and the conveyed materials will not be polluted, no peculiar smell will leak out, and the sanitation of the conveying environment will be guaranteed.

4. Flexible layout: Different layout methods can be adopted according to the conveying site. It can be conveyed horizontally or with a small inclination angle, and the inclination angle is not more than 25°.

When the sludge is discharged to the feed port on the U-shaped groove, the sludge is discharged from the outlet at the bottom of the U-shaped groove through screw drive. The sludge is like a fixed nut when it is working, and the shaftless screw is like a rotating bolt. The continuous rotation of the bolt can drive one end of the nut to the other end. The shaftless screw conveyor installed horizontally can use two filter presses and A centrifuge simultaneously collects the treated sludge and transports it to the next process.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

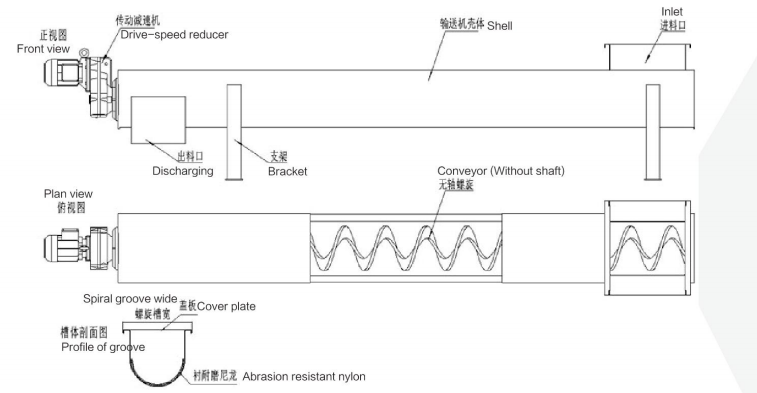

Sludge Shaftless Screw Conveyor is mainly composed of driving device, head assembly, casing, shaftless screw, tank liner, inlet, outlet, cover (if necessary), base, etc.

1. Driving device: Cycloidal pin wheel reducer or shaft-mounted hard-toothed gear reducer is used. When designing, the driving device should be installed at the end of the discharge port as much as possible, so that the spiral body is in a tensioned state during operation.

2. Case: The case is U-shaped, with a rain-proof cover on the top, made of stainless steel or carbon steel.

3. Shaftless helix: the material is stainless steel or carbon steel.

4. Lining plate of tank body: the material is wear-resistant plastic plate or rubber plate or cast stone plate, etc.

1. Conveying products and output: In fact, sludge is also classified into wet and dry. For sludge materials with different attributes, the selected screw conveyors are also different. Relatively dry sludge has higher requirements on sealing, which can prevent dust from appearing in the transportation process, while wet sludge has relatively strong entanglement, so the design is also different.

Different conveying volumes correspond to different models. The larger the output, the larger the selected Sludge Shaftless Screw Conveyor model.

2. Conveying speed: In general, the speed should not be too fast to prevent the increase of dynamic load.

3. User requirements: The selected Sludge Shaftless Screw Conveyor has different material particle sizes under different models, so it is necessary to select the corresponding model of equipment according to the material particle size required by the user.

Dahan, the manufacturer of shaftless sludge screw conveyor, is committed to providing high-quality conveying solutions for industries such as sewage treatment plants, tap water sedimentation tanks, urban water supply plants, and industrial wastewater treatment. With many years of manufacturing experience and technical accumulation, we are committed to providing customers with reliable and efficient sludge conveying equipment. Our shaftless sludge screw conveyor is specially designed for conveying sludge, mud cake, silt, mud and other materials, suitable for sludge treatment needs in different industries. If you are interested in our products or have any questions, please feel free to contact us. We look forward to working with you to provide you with high-quality sludge treatment equipment and services.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!