Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Special equipment for small output and small batch conveying of bulk materials, which can convey powdery, granular and small block materials horizontally, inclined or vertically, small in size, low in output and easy to move

Price: $500.00-$20,000.00/Set Chat Now

Model: 114mm, 159mm, 160mm, 250mm

Delivery capacity: 3-22 cubic/hour

Conveying length: 5-10 meters

Material: carbon steel, stainless steel

Installation angle: 0-90 degrees

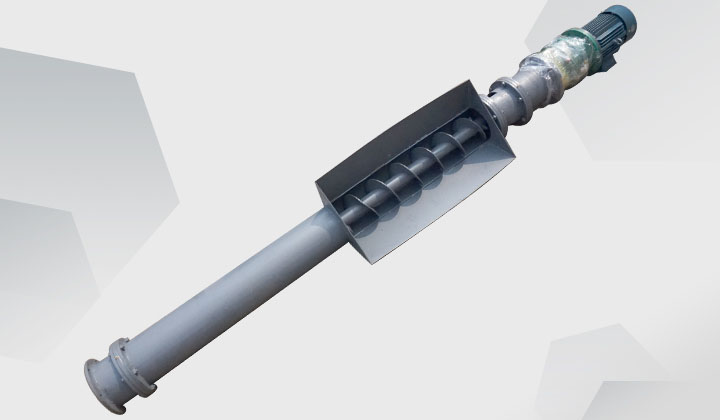

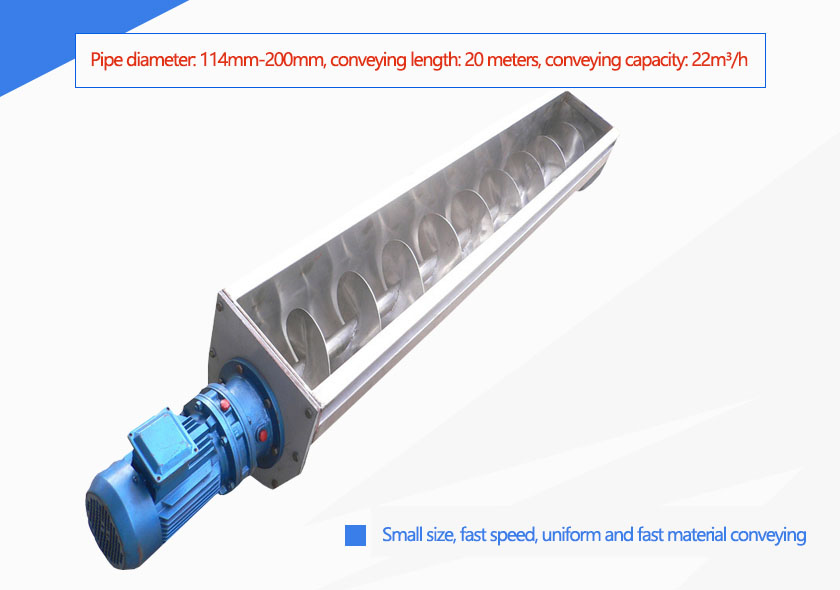

Small Screw Conveyor is specially designed for users who require a small amount of conveying. It adopts closed seamless steel pipe with high speed and uniform conveying materials. It can convey powdery, granular and small lump materials horizontally or inclined. The models include: 114mm, 159mm, 160mm, 250mm, the conveying capacity is 3-22 cubic meters per hour, and the conveying length can reach 5-10 meters.

Conveying chemical powder

conveying flour

Small screw conveyors can be divided into several different types according to their structure and purpose. The following are several common types of small screw conveyors:

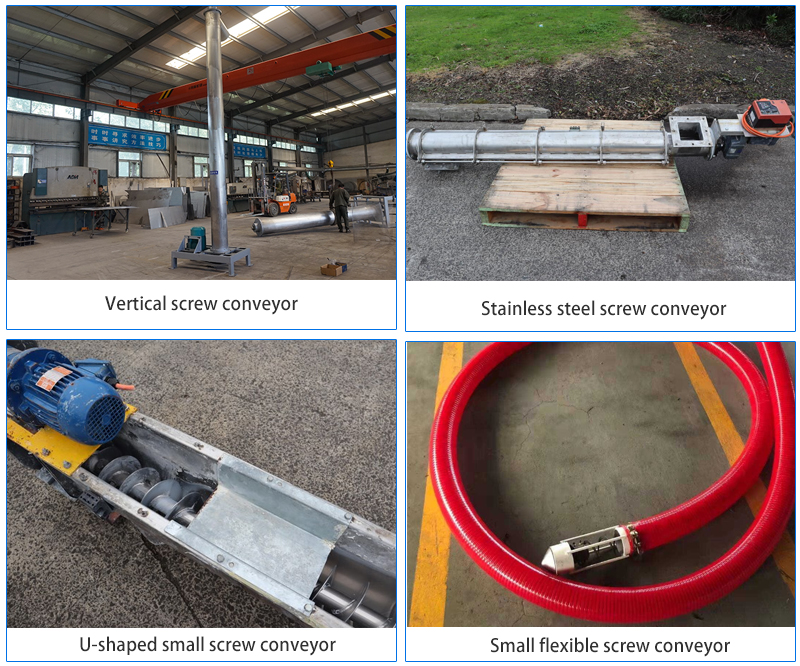

Vertical screw conveyor: This type of small screw conveyor is mainly used for material transportation in the vertical direction. It can be used to transport materials from one height to another, such as from the ground to the container upstairs.

Stainless steel screw conveyor: Stainless steel screw conveyors are suitable for occasions with high hygiene requirements, such as the food processing industry, and their materials will not be affected by the characteristics of the materials.

Small flexible screw conveyor: Usually used to handle the transportation of granular or powdered materials. This type of conveyor has a flexible spiral blade that can transport materials in horizontal, inclined or vertical directions.

U-shaped small screw conveyor: The conveying pipeline is designed in a U shape, which is suitable for conveying materials back and forth, such as conveying and distributing mixed materials.

Small Screw Conveyor can be used for horizontal or inclined conveying of powdery, granular and small block materials, such as cement, coal powder, chemical fertilizer, sand, coke, grain, etc. The temperature of the conveyed material should not exceed 200 ° C, widely used in building materials Electric power, chemical industry, metallurgy, coal, grain and other industries are not suitable for conveying viscous, perishable and agglomerated materials.

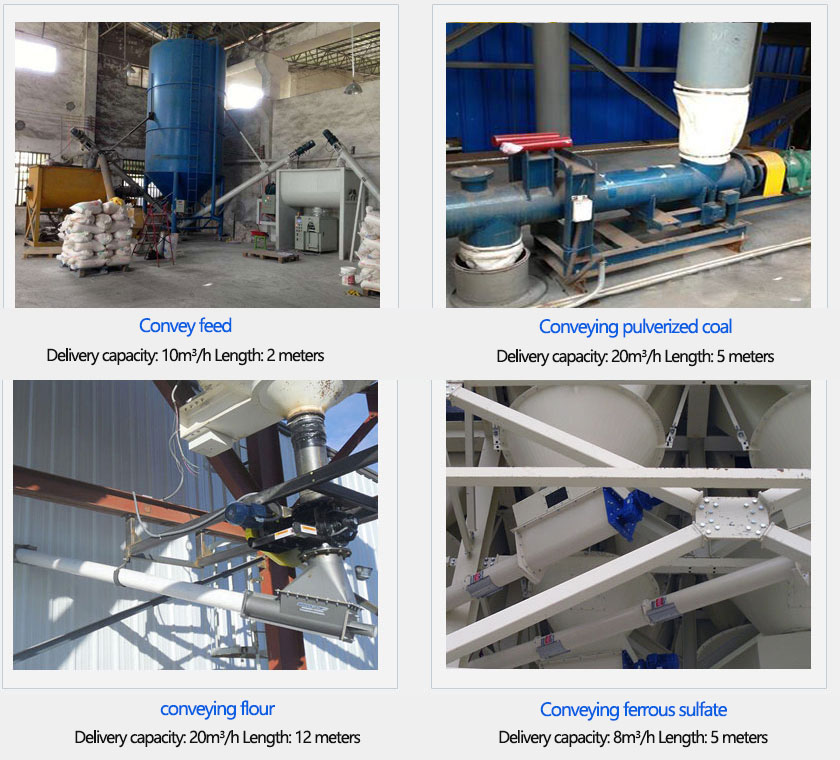

Agriculture: Small screw conveyors can be used to transport feed, helping farms to transport feed from storage areas to animal feeding areas, with a conveying capacity of 10m³/h and a length of 2 meters.

Food processing plants: Used to transport flour from storage areas to mixing or packaging equipment on production lines, with a conveying capacity of 20m³/h and a length of 12 meters.

Pulverized coal industry: Used to transport pulverized coal from storage areas to boilers or other combustion equipment, with a conveying capacity of 20m³/h and a length of 5 meters.

Chemical plants: Used to transport ferrous sulfate, transporting chemical raw materials to reaction tanks or mixing equipment for production processes, with a conveying capacity of 8m³/h and a length of 5 meters.

1. Small diameter, fast speed, uniform feeding, the conveying volume is between 3-22 cubic meters per hour, and the conveying length is 5-10 meters.

2. Small size, small footprint, flexible matching, light and convenient.

3. The discharge port is equipped with a cleaning device, so that the material is not easy to be blocked.

4. The conveying direction of the feeding material is reversible, and the material can be fed in two directions at the same time.

5. The whole machine is tightly sealed, which can play a good role in dust prevention. It can effectively isolate those materials with high hygienic requirements or materials with strong odor, and meet customer requirements.

The Small Screw Conveyor uses the rotating helical blade to push the material forward until it is discharged from the outlet. During this period, the force that keeps the material from rotating with the blades of the screw conveyor is the weight of the material itself and the frictional resistance of the screw conveyor casing on the material.

| Types | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 |

| Rotating speed(r/min) | 100 | 120 | 90 | 90 | 75 | 75 |

| Capacity Qφ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 |

| Power Pd 1=10m(kw) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 |

| Specification only for your reference, size variable as per customer's request. Note: Please use other types of screw conveyors of our company for those larger than 1000 kg/h. | ||||||

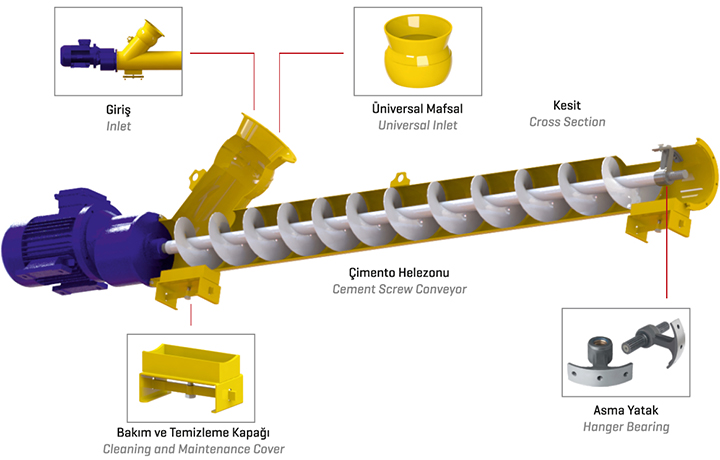

The components of a small screw conveyor together form the structure of a small screw conveyor, enabling it to transport and handle materials efficiently and reliably.

Screw conveyor frame: The frame is the supporting structure of the conveyor, usually made of carbon steel and stainless steel to ensure the stability and durability of the conveyor.

Screw shaft: The screw shaft is the main transmission component of the conveyor, usually made of steel, and the spiral blades are fixed to the screw shaft. The rotation of the screw shaft drives the spiral blades to transport the material along the conveyor.

Spiral blades: The spiral blades are spiral flat blades connected to the screw shaft, which are used to transport materials along the conveyor.

Inlet and outlet: The inlet is used to put materials into the conveyor, and the outlet is used to discharge materials. These two parts are usually located at both ends of the conveyor to ensure that the materials enter and exit the conveyor smoothly.

Transmission: The transmission device usually consists of a motor, a reducer and a coupling to drive the screw shaft to rotate, thereby realizing the conveying of materials.

As a professional manufacturer of small screw conveyors, we are committed to providing customers with high-quality and reliable conveying solutions. We can customize small screw conveyors of various specifications and functions according to customer needs. We have carbon steel, stainless steel, and flexible screw conveyors that can meet the material conveying needs of different industries. The conveying capacity can reach 3-22 cubic/hour, and the price is between $300.00-$1,000.00/Set. If you are looking for conveying equipment, please feel free to contact us, we will make a perfect solution and quotation for you!

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!