Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

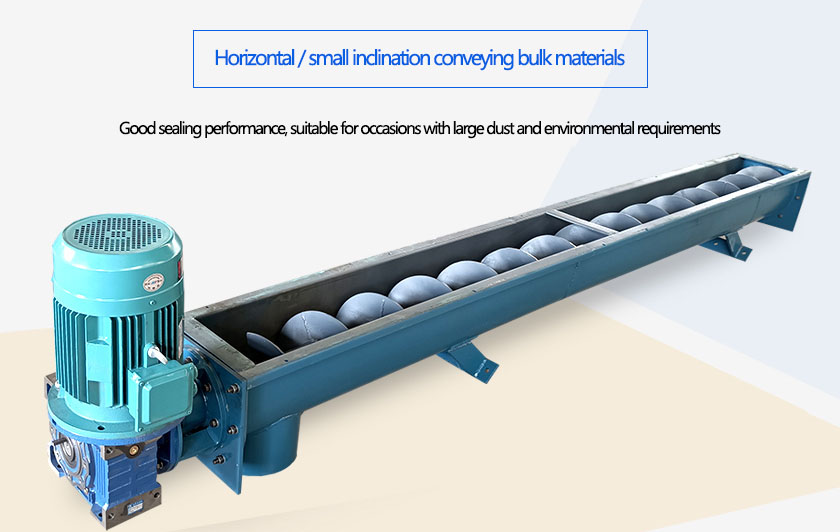

U-Shaped Screw Conveyor is a general solution for bulk and powder material handling, it can convey materials in a small range or a small inclination (15°).

Price: $350.00-$3,600.00/Set Chat Now

Pipe diameter: 100mm-600mm

Delivery capacity: 134 cubic / hour

Length: 10-20 meters

Type: with shaft, without shaft

Material: carbon steel, stainless steel

Materials: starch, mud, sawdust, chicken manure, rubber granules, sludge, silt, fodder, etc.

U-Shaped Screw Conveyor is also called U-shaped groove screw conveyor, which has a "U" shape and can convey powdery, granular and small pieces of materials in a small range or a small inclination angle (15°); it can feed in the middle and discharge on both sides Or feeding on both sides and discharging in the middle, the conveying direction can be reversed, or can be conveyed in two opposite directions at the same time; the upper part of the conveyor is equipped with a rainproof cover, which has good sealing performance, and the conveying process is a closed conveyance, which can effectively reduce indoor odor Leakage or entry of external dust has great advantages for occasions with large dust and environmental requirements.

conveying flour

U-Shaped Screw Conveyor is a general solution for handling bulk materials such as powder, granules, and small blocks. Commonly used materials include: cement, coal powder, fly ash, and starch. Grain, chemical fertilizer, concrete, ash, sand, coke, sludge, mud cake, chicken manure, rubber granules, industrial waste, etc., often used in garbage treatment plants, sewage treatment plants, industrial waste treatment, cement batching plants, building materials, In industries such as chemical industry, coal, grain and food, it is not allowed to transport materials that are perishable, highly viscous and easy to agglomerate.

1. The structure is divided into shaftless and shaft

U-Shaped Shaftless Screw Conveyor: Granular/powder materials, wet/paste materials, semi-fluid/viscous materials, easily entangled/clogged materials, materials with special hygienic requirements.

U-Shaped Shaft Screw Conveyor: Ordinary material conveying, not easy to convey sticky materials, has certain requirements on the wear resistance of the screw conveyor.

2. The material is divided into carbon steel and stainless steel

Carbon steel U-Shaped Screw Conveyor: mainly used in cement, coal, stone and other industries with high wear and no special requirements for steel.

Stainless steel U-Shaped Screw Conveyor: It is mainly used in grain, chemical, food and other industries that have requirements on the conveying environment. It has a high degree of cleanliness and will not pollute the materials.

Small-scale conveying: U-shaped groove design, suitable for conveying materials horizontally or with a small inclination angle, and the inclination angle is not easy to exceed 15°.

Large conveying capacity: the conveying length of a single machine can reach 40 meters, and the conveying capacity per hour is 458m³/h.

Multi-point loading and unloading: it can be loaded and unloaded at any point on the conveyor line, and it is easy to use when loading and unloading in the middle.

No material blockage, no dust: the discharge port is equipped with a cleaning device, the material will not be blocked, and the sliding bearing is equipped with a dust-proof sealing device, which has a good sealing effect.

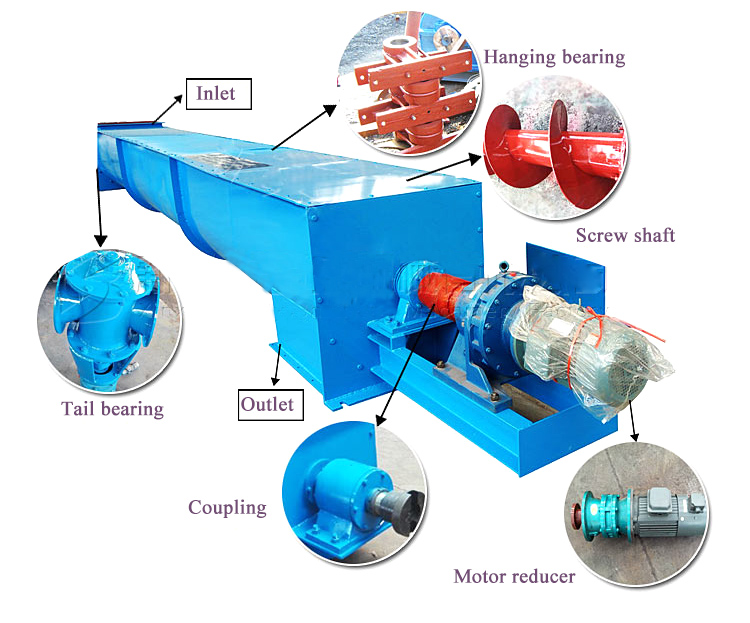

U-Shaped Screw Conveyor is mainly composed of driving device, head assembly, casing, screw body, tank liner, inlet, outlet, cover (if necessary), base, etc.

1. Driving device: Cycloidal pin wheel reducer or shaft-mounted hard-toothed gear reducer is used. When designing, the driving device should be installed at the end of the discharge port as much as possible, so that the spiral body is in a tensioned state during operation.

2. The head is equipped with a thrust bearing, which can withstand the axial force generated when conveying materials.

3. Spiral blade: the general material is stainless steel or carbon steel. If the service life is considered, it is recommended to use high-strength wear-resistant steel screw conveyor blades.

4. Chassis: U-shaped trough, with a rainproof cover on the upper part, made of stainless steel, carbon steel or glass fiber reinforced plastic.

5. Lining plate of tank body: It is made of high-strength engineering plastic polymer polyethylene, which has weak adsorption, non-stick material, wear resistance and corrosion resistance.

6. Inlet and outlet: There are two types of square and round. Generally, the form of inlet and outlet is determined by the user.

When the U-Shaped Screw Conveyor is working, the material enters the U-shaped groove from the inlet, and the forward power generated by the rotation of the helical blade is used to push the material forward until the delivery is completed at the outlet. The reason why the material does not rotate with the blades in this process is because one is the gravity of the material itself, but the frictional resistance generated by the inner shell of the equipment on the material.

U-Shaped Screw Conveyor models include U200, U250, U300, U400, U500, U600, etc.

| Specification | Main technical performance | drive unit | drive unit | Weight (kg) | |||

| diameter | length (m) | Output (cement) t/h | speed(min) | reducer | electric motor | ||

| model | speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

Conveying materials

Powdery dry material, the specific gravity is not easy to be too heavy.

Delivery length

The larger the inclination angle (preferably within 15°), the longer the conveying length should not be.

Motor Power

The power of the selected motor is determined according to the conveying length, inclination angle, conveying capacity, etc., and the selected motor power is large or not small.

Spiral speed

According to the specification, model and inclination angle, the speed of the U-shaped screw conveyor is selected. The larger the inclination angle, the faster the speed.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!