Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

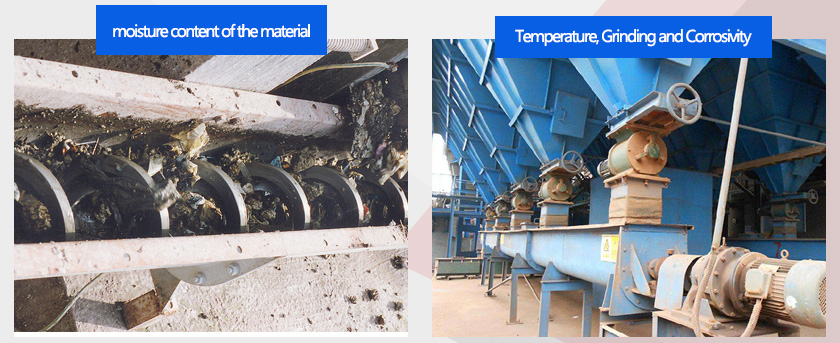

The water content of the material is high, and the material is easy to adhere to the spiral blade or the inner wall of the Auger Conveyor during the conveying process, which affects the conveying efficiency.

The long-term conveying of the screw conveyor in a high-temperature, high-abrasive, and highly corrosive environment will cause damage to the pipe wall and other parts in contact with the material, and even cause material leakage.

The conveyor should be installed in a stable and well-closed place.

Materials with different properties have different requirements on the blade shape of Auger Conveyor.

The faster the speed of the screw conveyor, the better the conveying effect, but the speed must meet the critical speed standard.

The larger the diameter, the better the effect, but for the open screw conveyor, the outer diameter of the screw will increase the manufacturing cost, and it is not conducive to cooling. In addition, the value of the outer diameter does not necessarily have to be an integer multiple of 500.

The size of the screw pitch is related to the speed of material conveying. The larger the screw, the larger the corresponding screw outer diameter. After the screw outer diameter is determined, there is a minimum pitch corresponding to it, that is, a more suitable pitch.

There are two typical feeding methods for Auger Conveyor: horizontal type and gravity type. The so-called horizontal feeding means that through a certain method (air force, horizontal spiral, etc.), the material particles can obtain a horizontal velocity, and the material is transported to the feeding port through a horizontal guide device to wait for delivery; Feeding in the way of falling in the direction, the material is transported to the feeding port of the screw conveyor through the flow guide device and waits to be transported.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!