Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

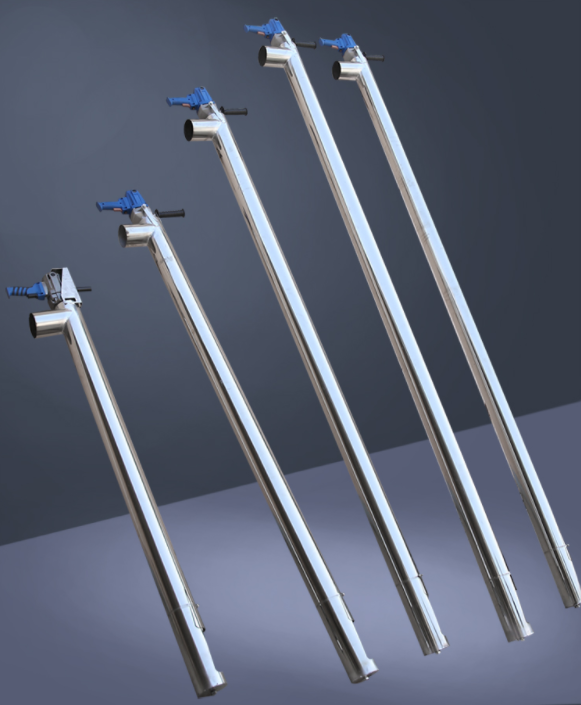

Stainless steel grain suction machine for chemical pellets is a kind of equipment specially used for sucking various chemical particles. It is usually made of stainless steel, with the characteristics of corrosion resistance, high temperature resistance, easy cleaning, etc., which is very suitable for use in chemical laboratories, pharmaceutical industry, food processing and other fields.

The working principle of the stainless steel chemical particle suction machine is generally as follows:

Particle suction: First, the equipment sucks chemical particles or granular materials from one place into the inside of the equipment by sucking airflow.

Transportation: The inhaled particles are transported to the conveying pipe or container inside the equipment.

Separation and filtration: During the transportation process, the equipment may separate and filter the particles to ensure that the conveyed particles meet the requirements while preventing impurities from entering.

Discharge: Finally, the processed particles are transported to the target location, which can be another container, production line or other required place.

Stainless steel chemical particle suction machine has been widely used in many fields due to its corrosion resistance, adjustable suction, high filtration accuracy and easy operation. The following are its main application scenarios: Chemical laboratory: reagent suction, accurate suction of various chemical reagents, powders, and particles to avoid pollution and waste; suction of solid waste generated by experiments to keep the laboratory clean.

Pharmaceutical industry: API suction, suction of various drug intermediates and powder raw materials to ensure the cleanliness of the production process; suction of excess powder in the process of drug packaging to improve production efficiency.

Food processing: Food additive suction: suction of food additives, seasonings, etc. to avoid cross contamination; in the food production line, the powdered raw materials are transported to the designated location.

Electronic industry: suction of fine particles on electronic components and circuit boards to prevent short circuits; removal of dust in the production workshop to improve the production environment; cleaning of dust and particles on precision instruments.

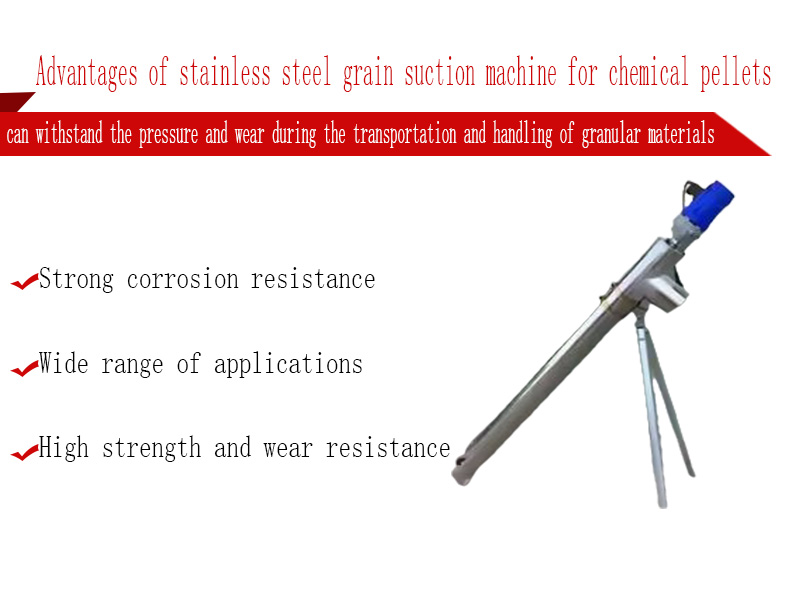

Stainless steel chemical particle suction machine has some obvious advantages over equipment made of other materials, including:

Strong corrosion resistance: Stainless steel has good corrosion resistance and is suitable for handling corrosive materials such as chemical particles, extending the service life of the equipment.

Easy to clean and hygienic: Stainless steel has a smooth surface, is easy to clean, meets hygiene standards, and is suitable for occasions with strict hygiene requirements in industries such as food and pharmaceuticals.

High strength and wear resistance: Stainless steel has high strength and wear resistance, and can withstand the pressure and wear during the transportation and handling of granular materials.

Good oxidation resistance: Stainless steel has good oxidation resistance, is not easy to rust, and maintains the appearance and function of the equipment for a long time.

Wide range of applications: Stainless steel chemical particle suction machine is suitable for a variety of fields, including chemical, food, pharmaceutical, environmental protection and other industries, and has a wide range of application prospects.

When choosing a stainless steel chemical particle suction machine, you can consider the following factors to make the selection:

Processing capacity: Determine the type, density and processing volume of the particles you need to process, and choose a suction machine with suitable processing capacity.

Material and corrosion resistance: Make sure to choose stainless steel material to ensure that the equipment has good corrosion resistance and is suitable for processing chemical particles.

Cleanliness: Consider the cleaning performance of the equipment and ensure easy-to-clean design to meet hygiene standards.

Functional performance: According to actual needs, choose equipment with functions such as suction, conveying, and filtering.

Applicable environment: Consider the environmental conditions where the equipment will be placed, such as temperature, humidity, etc., and choose a suitable model.

In short, the stainless steel grain suction machine for chemical pellets is a safe laboratory equipment, which is widely used in the fields of chemistry, pharmaceuticals, food, etc.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!