Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Tubular Screw Conveyor is welded by seamless steel pipe, the thickness of the pipe wall is ≥10mm, it adopts the design of small diameter, high speed, variable pitch, etc., no material jam, large conveying capacity, conveying distance up to 70 meters, horizontal/vertical/inclined conveying Powder, granular material.

Tube wall thickness: ≥10mm

Diameter: 100mm-1250mm

Delivery capacity: 142 cubic / hour

Length: 2-70 meters

Materials: flour, fly ash, cement, coal powder, corn, wheat, coal and other powdery/granular/small lump materials

Select material: carbon steel, stainless steel

Choose an angle: horizontal, oblique, vertical

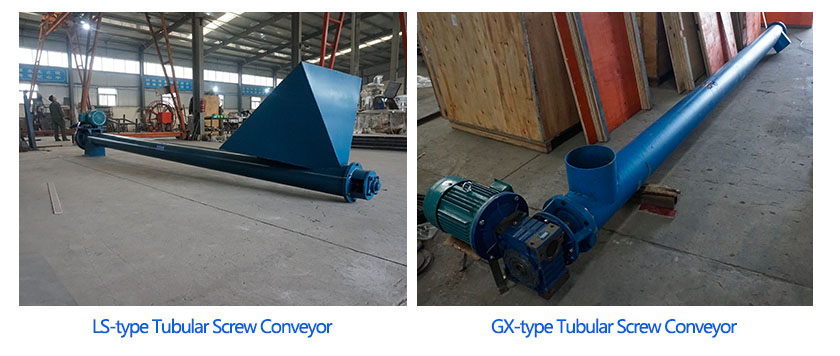

Tubular Screw Conveyor, also known as round tube screw conveyor, is welded by seamless steel pipe with a wall thickness of 10mm, and has good sealing performance; it can be used for horizontal or inclined conveying of powder, granules and small block materials (GX type inclination angle < 200° , LS-type inclination <150°), provide three materials of low carbon steel (painted or galvanized), stainless steel and plastic to meet customer requirements and site environment, Tubular Screw Conveyor pipe diameter range 100mm-1250mm, all machines are available Tailored to suit individual needs.

Tubular Screw Conveyor can be used in food, medicine, building materials, electric power, metallurgy, chemical industry and other industries. It can convey powdery, lumpy and granular materials, such as flour, grain, cement, fertilizer, ash, sand, stone, coal powder, lump Coal, calcium carbonate, soda water, sand, dry plaster, fly ash, additives and other materials.

1. GX-type Tubular Screw Conveyor: There are seven specifications of screw diameters: 150, 200, 250, 300, 400, 500, and 600mm. The shortest fuselage is 3m, and the longest can reach 70m. It is necessary to form a corresponding conveying system for one-way conveying with a horizontal or inclination angle less than 20°.

2. LS-type Tubular Screw Conveyor: It is a replacement product of GX-type screw conveyor. The screw diameter is 100-1250mm, and there are eleven specifications. The driving mode has two forms: single-end drive and double-end drive; LS-type screw feeder The length of the fuselage is in a gear of 0.5m, and the corresponding conveying system can be formed according to the needs of different sites. Like the GX screw conveyor, it is used for one-way conveying with a horizontal or inclination angle less than 20°. The working environment temperature is usually -20~50°C , The conveying material temperature is less than 200°C.

The simple design, reliability and easy maintenance of the tubular screw conveyor make it a popular choice for effectively conveying bulk materials. Here are some of its main features:

1. Widely applicable: It can be used to convey materials that are not easy to deteriorate, have high viscosity and are easy to agglomerate, indicating that it is widely applicable and can handle a variety of materials.

2. Convenient maintenance: The screw shaft, hanging bearing, head and tail shafts are connected by mortise and tenon type, and no axial movement is required during installation and removal, which is convenient for maintenance.

3. Not easy to get stuck: Each transmission part adopts a floating connection method, which can rotate and avoid freely within a certain range according to the conveying resistance, avoiding the occurrence of stuck or blocked materials, and improving the smoothness of operation.

4. Long life: The variable diameter structure is adopted to increase the volume of the hanging bearing, avoid direct contact between the hanging bearing and the material, thereby extending the service life of the hanging bearing, which can reach more than two years.

5. Sealing structure: The sealing tube design is adopted, so when conveying powdery materials, dust overflow can be avoided to cause environmental pollution.

6. Flexible layout: It can be conveyed horizontally, inclined, vertically, and linked with other equipment.

Tubular screw conveyor is a common conveying equipment, and its main components usually include the following parts:

Spiral blade: Responsible for moving the material along the axis of the conveyor.

Trough: The trough is the container of the spiral blade and provides a channel for material transmission.

Drive device: The drive device provides power for the conveyor, usually using an electric motor or other power source to drive the spiral blade to rotate, thereby promoting material transportation.

End bearing: The end bearing supports the spiral shaft of the conveyor to maintain its stable operation in the trough.

Feed port and discharge port: The feed port is where the material is input into the conveyor, and the discharge port is where the material is discharged from the conveyor.

The Tubular Screw Conveyor uses the rotating helical blades to push the materials to be transported by the screw conveyor. The force that prevents the materials from rotating together with the screw conveyor blades is the material's own weight and the frictional resistance of the screw conveyor casing to the materials.

| LS type | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| GX type | 200 | 250 | 300 | 400 | 500 | ||||||

| Spiral diameter (mm) | 100 | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 |

| Pitch (mm) | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 | 560 | 630 |

| Speed (r/min) | 140 | 120 | 90 | 90 | 75 | 75 | 60 | 60 | 45 | 35 | 30 |

| Delivery capacity QΦ=0.33 (m³/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 | 93.1 | 160 | 223 | 304 | 458 |

| 功率Pd 1=10m(KW) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 | 4.1 | 8.6 | 12 | 16 | 24.4 |

| Power Pd 1=30m (KW) | 1.6 | 2.8 | 3.2 | 5.3 | 8.4 | 11 | 15.3 | 25.9 | 36 | 48 | 73.3 |

| Speed (r/min) | 120 | 90 | 75 | 75 | 60 | 60 | 45 | 45 | 35 | 30 | 20 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.9 | 5.7 | 18 | 18 | 29.1 | 52.9 | 69.8 | 125 | 174 | 261 | 305 |

| Power Pd 1=10m (KW) | 1.0 | 1.3 | 2.1 | 2.1 | 2.9 | 4.1 | 4.7 | 6.8 | 9.4 | 14.1 | 16.5 |

| Power Pd 1=30m (KW) | 1.5 | 2.3 | 4.5 | 4.5 | 7 | 8.9 | 11.6 | 20.4 | 28.3 | 42.2 | 49.5 |

| Speed (r/min) | 90 | 75 | 60 | 60 | 45 | 45 | 35 | 35 | 30 | 20 | 16 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.4 | 4.8 | 15 | 15 | 21.8 | 39.6 | 54.3 | 97 | 149 | 174 | 244 |

| Power Pd 1=10m (KW) | 0.9 | 1.2 | 1.9 | 1.9 | 2.5 | 3.4 | 4.3 | 5.4 | 8.1 | 9.5 | 13.3 |

| Power Pd 1=30m (KW) | 1.2 | 2.2 | 3.8 | 3.8 | 5.4 | 6.8 | 9.2 | 16 | 24.4 | 28.6 | 39.9 |

| Speed (r/min) | 75 | 60 | 45 | 45 | 35 | 35 | 30 | 30 | 20 | 16 | 13 |

| Delivery capacity QΦ=0.33 (m³/h) | 1.2 | 3.8 | 11 | 11 | 17 | 31.7 | 46.5 | 73.0 | 99.3 | 139 | 199 |

| Power Pd 1=10m (KW) | 0.75 | 1.1 | 1.6 | 1.6 | 2.1 | 3.1 | 3.7 | 4.6 | 5.7 | 7.7 | 11 |

| Power Pd 1=30m (KW) | 1.1 | 1.8 | 3.4 | 3.4 | 4.4 | 5.6 | 8 | 14 | 16.7 | 23.2 | 33 |

1. Material: carbon steel or stainless steel can be selected according to the conveying material.

2. Inclination angle: It can be designed according to the user's requirements for horizontal or large inclination angles. The inclination angle of LS type is ≤15°, and the GX tubular screw conveyor can be selected if the inclination angle is greater than 20°. The inclination angle is ≤45°. The maximum angle of the shaftless tubular screw conveyor is 30°.

3. Conveyor length: the diameter ranges from 100mm to 1250mm, a total of twelve specifications, divided into two forms of single drive and double drive, the length of single drive screw machine can reach 40 meters (extra large 30 meters), double drive screw machine It adopts the structure of broken shaft in the middle, and the length can reach 80 meters (60 meters for extra-large), and the length of the screw machine is 0.5 meters. One gear can be selected according to needs.

4. Conveying direction: It can be conveyed in reverse, and a conveyor can also convey materials in two directions at the same time, that is, to the center or away from the center.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!