Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

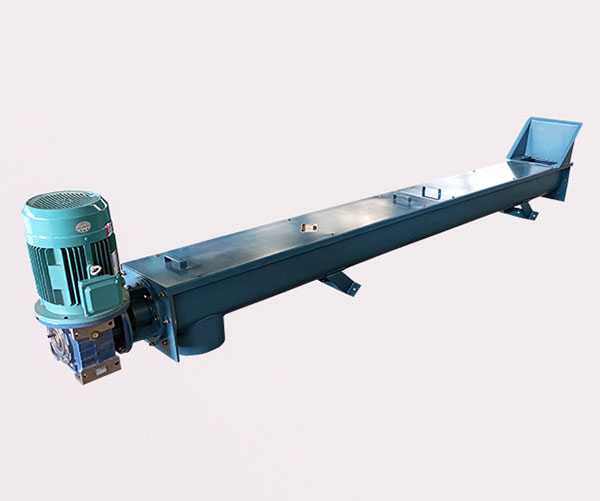

Screw conveyor is a commonly used conveying equipment, which conveys materials from one end to the other through spiral rotation, and is widely used in chemical industry, building materials, food, metallurgy, electric power and other industries.

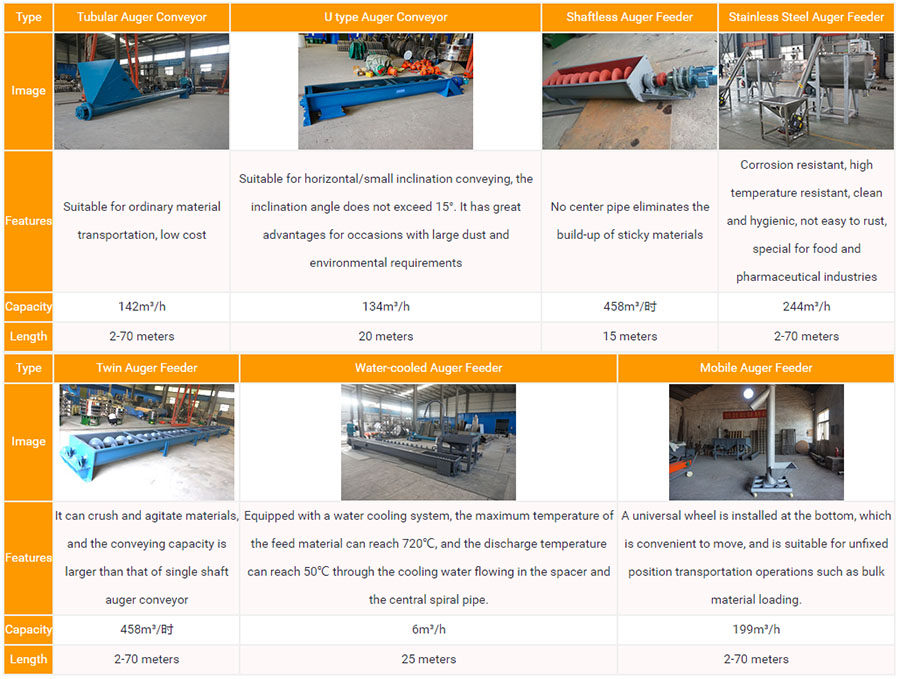

According to the nature of the conveyed material and the different conveying forms, the screw conveyor mainly has the following types:

(1) According to the nature of the conveyed material:

① Ordinary screw conveyor: suitable for conveying powdery, granular and small block materials.

②Screw conveyor with central shaft: suitable for conveying viscous materials, such as sludge, asphalt, etc.

③Screw conveyor with shaftless screw: It is suitable for conveying materials with strong fluidity, such as protein powder, cement, coal powder, etc.

(2) According to the delivery form:

①Horizontal screw conveyor: The conveying line is in the horizontal direction, and it is used in the occasions where the conveying distance of materials is short and the dust pollution is small.

② Inclined screw conveyor: The conveying line is inclined, which is suitable for conveying materials with high height.

③Vertical screw conveyor: The conveying line is vertical, suitable for conveying high temperature, high humidity and corrosive materials.

(1) Simple structure and easy maintenance.

(2) Large conveying capacity and wide application range.

(3) The ability to adapt to environmental changes is strong, and dustproof and waterproof treatment can be carried out as needed.

(4) There is no accumulation or material jam during the conveying process, and the conveyed materials are not easy to break.

(5) The range of temperature and humidity of conveyed materials is relatively wide, and the restrictions on materials are relatively small.

The screw conveyor is mainly composed of a screw, a conveying pipe, a transmission mechanism, and a supporting device. When the transmission mechanism drives the screw to rotate, the material follows the screw and advances along the conveying pipe to finally reach the destination. Among them, the design of the screw is closely related to the properties of the conveyed material and the process requirements, including the diameter of the screw, the pitch, the thickness and angle of the screw plate, etc.

Screw conveyors are widely used in chemical industry, building materials, food, metallurgy, electric power, mining and other industries. The following are some specific application materials:

(1) Chemical industry: potassium chloride, sulfuric acid, polyethylene, polypropylene, polyvinyl chloride, etc.

(2) Building materials industry: cement, lime, gypsum, coal powder, ash, etc.

(3) Food industry: flour, feed, fruit juice, hops, etc.

(4) Metallurgical industry: ore, coke, coal, etc.

(5) Power industry: ash, coal ash, etc.

(6) Mining industry: ore, slag, coal gangue, etc.

The sulfuric acid conveying line of a chemical company adopts horizontal screw conveyors, the conveying capacity of each machine is 5 tons/hour, and the conveying distance is 20 meters. The material of the screw conveyor is carbon steel, the diameter of the conveying pipe is Φ200mm, and the pitch of the screw is 150mm. The bottom of the machine adopts a shockproof bracket. The overall structure is compact, safe and reliable, which greatly improves the production efficiency.

conveying sawdust

In short, as an important mechanical equipment, screw conveyor plays a vital role in industrial production. It has a wide range of applications, high transmission efficiency, and long service life. It is one of the indispensable equipment for industrial production and is of great significance for improving production efficiency and reducing transportation costs.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!