Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

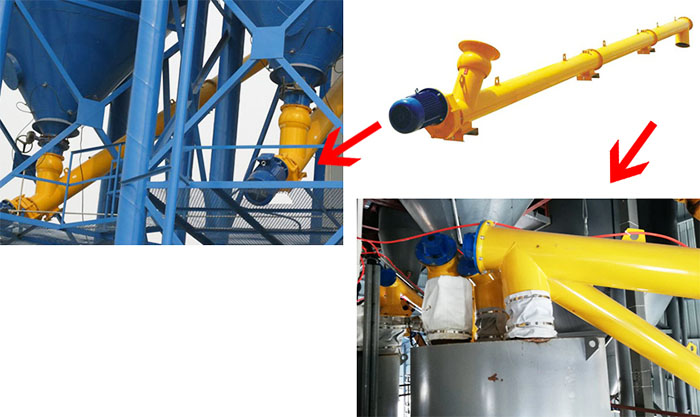

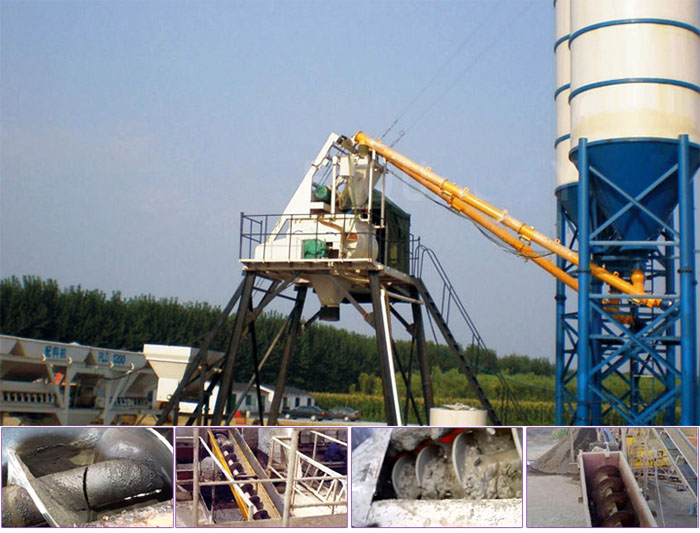

Cement Screw Conveyor is a conveying equipment mainly used for conveying bulk materials such as cement, coal powder and ash powder. It has been widely used in various industrial productions. With the continuous upgrading of the demand for conveyors in different industries, various types of Cement Screw Conveyor have also emerged as the times require. A suitable Cement Screw Conveyor model can better adapt to the working environment and actual needs, so as to achieve the best conveying effect.

According to different classification standards, Cement Screw Conveyor can be divided into various models. According to the needs of conveying distance and conveying volume, it can be divided into short-distance screw conveyor and long-distance screw conveyor; according to the conveying method, it can be divided into straight type and curved type; according to the conveying angle, it can be divided into horizontal type, inclined type and vertical type. etc.

Specifically, according to the transmission mode, it can be divided into electric Cement Screw Conveyor and manual Cement Screw Conveyor; according to the diameter and pitch of the screw, it can also be divided into LX type Cement Screw Conveyor, LS type Cement Screw Conveyor and GX type Cement Screw Conveyor ; According to the shape of the cylinder, it can be divided into U-type Cement Screw Conveyor, T-type Cement Screw Conveyor, O-type Cement Screw Conveyor, S-type Cement Screw Conveyor, etc.

Different models of Cement Screw Conveyor have their own characteristics, which can meet the needs of different industries and occasions. The following are several common models and their characteristics and delivery capacity indicators:

1. LS type Cement Screw Conveyor

LS type Cement Screw Conveyor has the characteristics of simple structure, high reliability, convenient installation and maintenance. The maximum conveying capacity is 600m³/h, and the conveying distance can reach 60m, which is suitable for conveying bulk materials such as cement and coal powder.

2. GX type Cement Screw Conveyor

GX type Cement Screw Conveyor is suitable for conveying powdery and granular materials such as cement, coal powder and ash powder. It has the characteristics of high reliability, small size and light weight. The maximum conveying capacity is 250m³/h, the conveying angle is 0°~45°, and the conveying distance can reach 20m.

3. U-shaped Cement Screw Conveyor

U-shaped Cement Screw Conveyor is small in size and simple in structure, and is suitable for continuous conveying of dry granular materials such as cement and coal powder. The maximum conveying capacity is 30t/h, and the conveying distance can reach 16m.

4. T-type Cement Screw Conveyor

The T-type Cement Screw Conveyor is similar to the U-type, but can achieve a longer conveying distance, and is suitable for conveying bulk materials such as cement and coal powder. The maximum conveying capacity is 40t/h, and the conveying distance can reach 20m. At the same time, this type of conveyor also has the characteristics of compact structure, small volume, and small transmission torque.

5. O-type Cement Screw Conveyor

O-type Cement Screw Conveyor is suitable for conveying bulk materials such as granular cement, automobile road roller, and concrete. The structure is simple, the shape is beautiful, and the transmission mode can be selected from motors, reducers and other methods. The maximum conveying capacity of this type of conveyor is 200 t/h, and the conveying distance can reach 50m.

Before actually choosing Cement Screw Conveyor, it is necessary to comprehensively consider various factors according to specific needs and material properties, and choose the appropriate model. The following is a simple Cement Screw Conveyor model parameter table for reference:

Model Conveying distance Conveying volume Conveying speed Spiral diameter

LS100 60m 16t/h 2.5~3.5m/s 100mm

GX219 20m 250m³/h 1.3~3.2m/s 219mm

U168 16m 30t/h 2.0~7.2m/s 168mm

T219 20m 40t/h 4.4~17.4m/s 219mm

O273 50m 200t/h 1.8~7.1m/s 273mm

In short, the selection of Cement Screw Conveyor model needs to be comprehensively evaluated based on comprehensive factors such as specific production requirements, material properties and working conditions, so as to achieve optimized conveying effect and production efficiency.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!