Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Cement Screw Conveyor is a commonly used material conveying equipment, which is mainly used in conveying cement, ash and powder materials. It has the advantages of long conveying distance, large conveying capacity and convenient installation. This article will introduce the structure and characteristics of Cement Screw Conveyor.

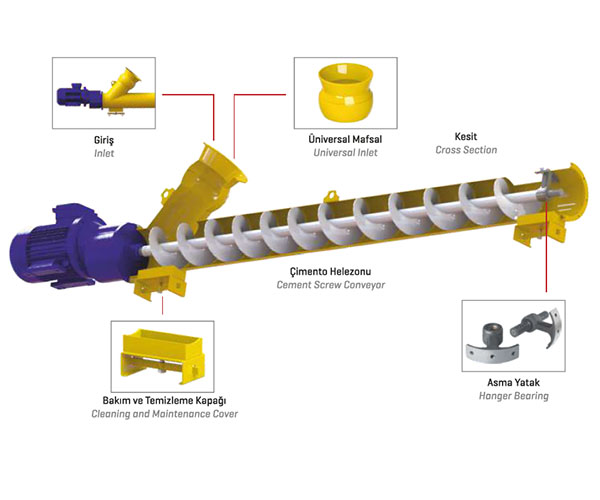

1. Spiral body: The spiral body is the main part of the Cement Screw Conveyor. It is a tubular structure composed of spiral blades. One end is connected to the feed port and the other end is connected to the discharge port.

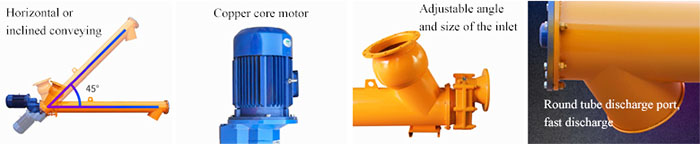

2. Motor: The motor is the main part to drive the Cement Screw Conveyor, and it can be selected according to different rated power and speed. Usually, the motor is connected to the reducer through a coupling, and the power output by the motor is transmitted to the reducer, which then drives the spiral tube body to rotate.

3. Reducer: The reducer is an auxiliary part of the Cement Screw Conveyor. It mainly plays the role of decelerating, converting the high-speed rotation output by the motor into low-speed and high-torque output. The selection of the reducer needs to be based on parameters such as the load characteristics and conveying distance of the Cement Screw Conveyor.

4. Bracket: The bracket is an important part of the Cement Screw Conveyor, and it mainly plays the role of supporting the spiral tube body. The structural form of the bracket usually has two kinds of triangular bracket and quadrilateral bracket, among which the triangular bracket is suitable for light load or short-distance transportation, and the quadrilateral bracket is suitable for heavy load or long-distance transportation.

5. Inlet and outlet: The inlet and outlet are important parts of the Cement Screw Conveyor. They are used for feeding and discharging materials respectively. The inlet is usually round or square, and the outlet is The mouth is usually rectangular or square. In order to ensure the continuous delivery of materials, a sealing device is usually set between the inlet and outlet.

1. Large transfer volume: Cement Screw Conveyor can meet the continuous transportation of a large amount of materials, and the transportation capacity is generally between 10-1000 cubic meters per hour.

2. Long conveying distance: Cement Screw Conveyor can realize long-distance conveying, and the conveying distance can be between 5-100 meters.

3. Simple structure: The structure of the Cement Screw Conveyor is relatively simple, mainly composed of a spiral tube body, a motor, a reducer, a bracket, a material inlet, and a material outlet, etc., and it is relatively convenient to install and maintain.

4. Wide range of applications: Cement Screw Conveyor is not only suitable for the transportation of cement and powdery materials, but also suitable for the transportation of chemical fertilizers, feed, coal, ore and other materials.

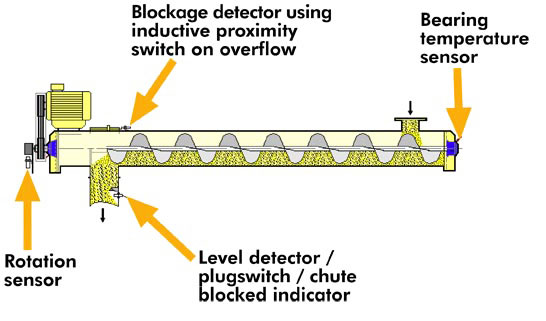

5. Stable operation: The operation of Cement Screw Conveyor is stable, and it is not easy to be blocked or fluctuated during the material conveying process. It can provide high-quality material conveying services for production enterprises.

To sum up, Cement Screw Conveyor is a widely used material conveying equipment, which has the characteristics of long conveying distance, large transshipment volume, simple structure, wide application and stable operation. In practical application, it is necessary to select different types and specifications of Cement Screw Conveyor according to different conveying requirements and process parameters to meet the requirements and needs of production enterprises.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!