Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

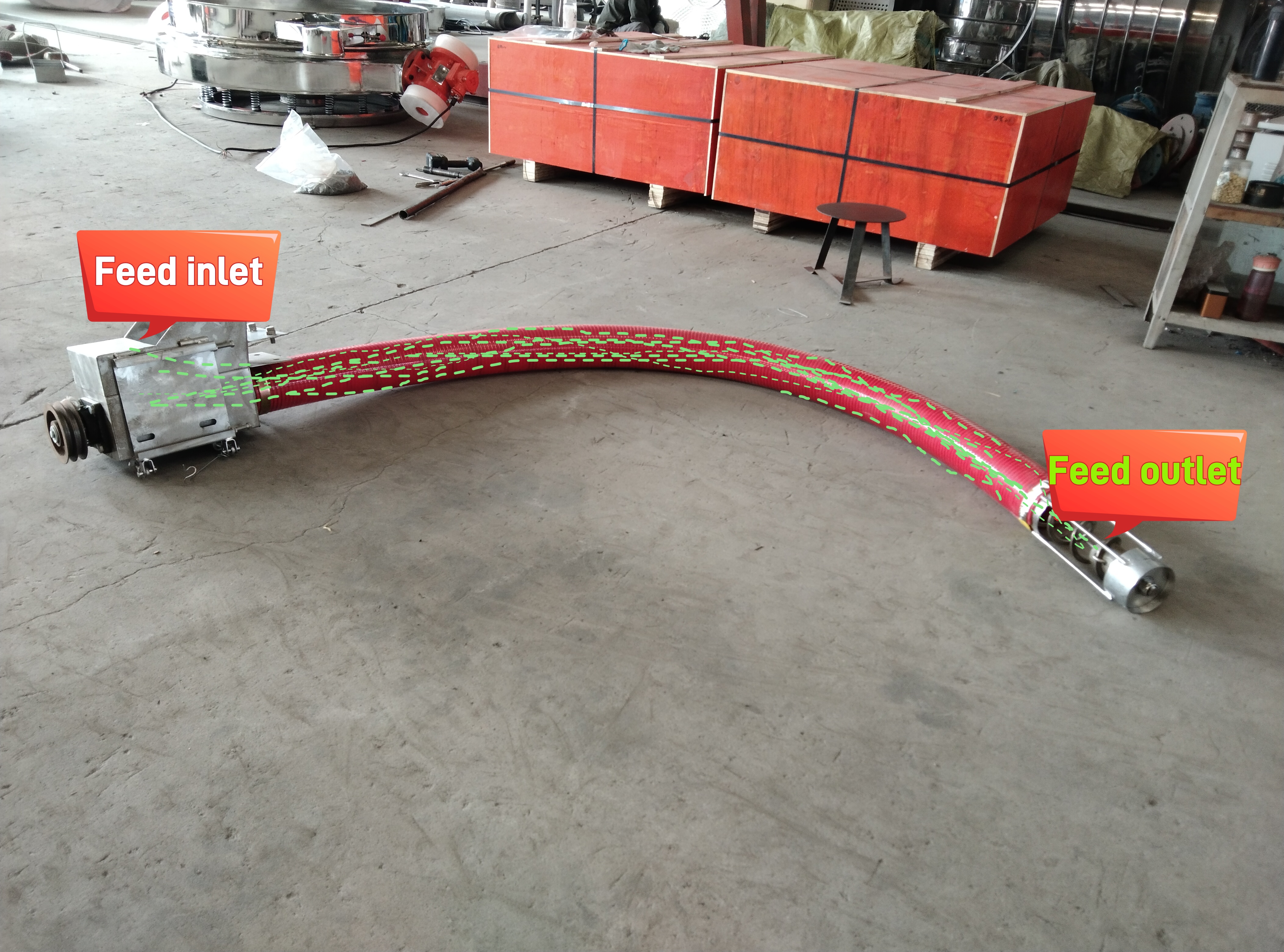

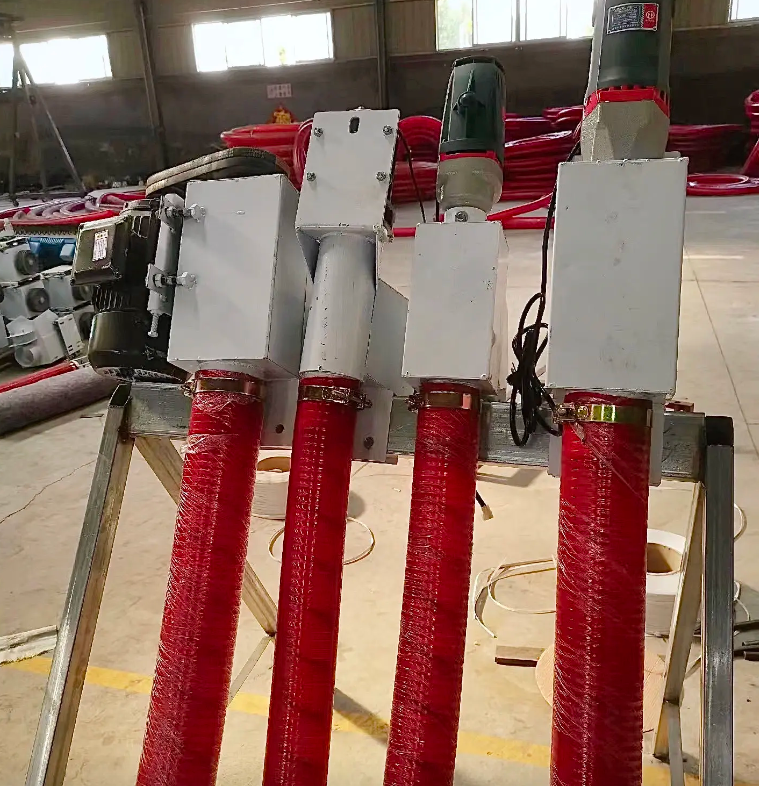

Feed Hose Screw Conveyor is a continuous conveying device that uses rotating spiral blades to push materials to move in a hose. Its main function is to transport feed from one place to another through spiral rotation. It is widely used in livestock and poultry farming, feed processing plants and other fields. This equipment uses a combination of hose and screw conveyor, which has the advantages of flexibility, reduced dust, and easy maintenance.

Compared with traditional conveying equipment, feed hose screw conveyors have the following significant advantages:

Convey a large amount of feed in a short time: The rapid rotation of the spiral blade can convey a large amount of feed in a short time, meeting the feed supply needs of large-scale breeding sites.

The feed delivery amount can be controlled: By adjusting the speed of the drive motor, the feed delivery amount can be accurately controlled, which is convenient for accurate feeding according to the feeding needs of animals at different breeding stages.

Strong adaptability: The flexibility of the hose allows the conveyor to be flexibly arranged and can adapt to the complex spatial layout in the farm. Whether in narrow passages or in environments that require turning and climbing, the feed delivery task can be successfully completed.

Good sealing: The entire conveying process is carried out in a closed hose, which effectively prevents the feed from contacting with the outside air during the conveying process, and reduces the risk of moisture, oxidation, and contamination of the feed.

When working, the drive device starts to drive the spiral blade to rotate at high speed in the hose. When the feed enters from the feed inlet, the rotation of the spiral blade generates axial thrust, just like the screw pushes the nut forward, pushing the feed forward along the inner wall of the hose. In this process, due to the close arrangement and continuous rotation of the spiral blades, the feed is stably and efficiently transported to the discharge port, completing the transfer from one place to another, and realizing the automated feed conveying process.

Feed hose screw conveyors have a wide range of application scenarios in the feed industry, mainly including but not limited to the following aspects:

Livestock and poultry farms: In livestock and poultry farms, feed hose screw conveyors are often used to transport feed from storage silos to equipment such as feed machines, feed troughs or feed mixers.

Feed processing plants: In feed processing plants, feed hose screw conveyors are usually used for the transportation and mixing of raw materials. It can transport various raw materials such as grains, soybean meal, fish meal, etc. to the mixer or pellet machine to realize the feed batching and processing process.

Feed storage: In the feed storage link, it can transport feed from the storage equipment to the packaging machine or directly load it for transportation, improving storage efficiency and operation efficiency.

Feed distribution vehicle: Feed hose screw conveyor can also be used on feed distribution vehicles to realize rapid loading and unloading of feed.

Feed production line: On the feed production line, the feed hose screw conveyor can be used as an important conveying equipment to quickly and continuously transport feed raw materials, semi-finished products or finished products in various production links.

The feed hose screw conveyor can transport various types of feed with its flexibility and adaptability, mainly including

1. Pellet feed: suitable for various livestock and poultry and aquatic animals. Pellet feed has good fluidity and is easy to transport, and is the main conveying object of the feed hose screw conveyor.

2. Powdered feed: such as soybean meal, corn meal, fish meal, etc. Powdered feed is easy to generate dust, and the airtight performance of the feed hose screw conveyor effectively prevents the spread of dust.

3. Broken feed: such as broken corn, broken wheat, etc. The particle size of broken feed is between granular feed and powdered feed, and the feed hose screw conveyor can also easily cope with it.

4. Other types of feed: such as puffed feed, fermented feed, etc. The feed hose screw conveyor can select suitable spiral blades and hose materials according to the characteristics of different feeds.

Viscous feed: For example, feed with high molasses content is easy to adhere to the spiral blades and the inner wall of the hose, affecting the conveying efficiency.

Feed with high fiber content: For example, hay, straw, etc., are easy to entangle the spiral blades and cause blockage.

Fragile feed: For example, puffed feed is easy to break during transportation, affecting the quality of feed.

In short, feed hose screw conveyors have a wide range of application scenarios in the feed industry. Through their flexibility, efficiency and reliability, they can provide convenient and efficient feed delivery solutions for livestock and poultry breeding, feed processing, feed storage and other links, promote the development of feed production and improve production efficiency.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!