Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

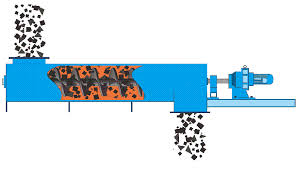

Ore Screw Conveyor uses the rotary motion of the screw shaft to push or lift the material along the pipeline to achieve material transportation. It can transport materials horizontally, inclined or vertically, and can be used to transport ore from the mine to the ore processing equipment or transportation vehicles.

As the source manufacturer of ore screw conveyors, our conveyors have different product advantages

* High efficiency and safe conveying capacity

* Easy to use and install, simple to operate

* Dust-free design, shaftless and shafted screws can be selected

* Low energy consumption and cost saving

* Support customized needs and screw conveyors of different materials

Ore screw conveyors have a wide range of application scenarios in the mining industry, mainly used for the transportation and processing of ore. The following are some application scenarios of ore screw conveyors:

Mines: often used to transport ore from the mining site to crushing equipment, grinding equipment or other processing equipment to achieve continuous transportation and processing of ore.

Ore dressing plant: used to transport ore that has been processed by crushing, grinding, etc. to flotation machines, dewatering machines and other equipment to achieve the transportation and sorting of ore during the beneficiation process.

Ore processing plant: used to transport ore products such as raw ore and ore powder to different processes on the ore processing production line, such as grinding, flotation, drying and other processes.

Ore transportation: used to unload ore from loading equipment such as trucks and conveyor belts, and transport it to storage equipment or production lines.

Coal mine: used for the transportation and processing of coal in coal mines to improve coal production efficiency.

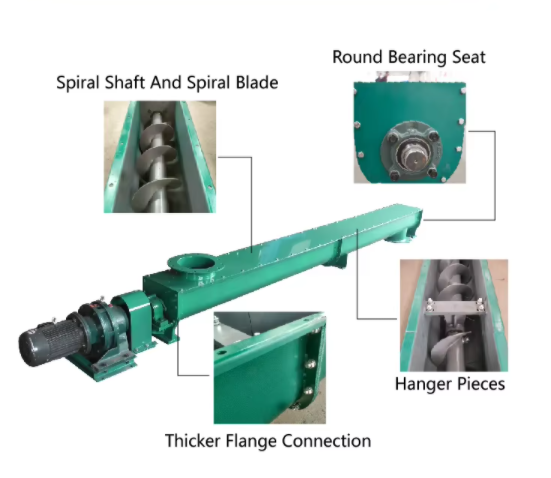

The main composition structure of the ore screw conveyor usually includes the following parts:

Screw shaft: It consists of a hollow screw shaft, and the spiral blades are fixed on the shaft. As the shaft rotates, the material is transported along the pipeline.

Spiral blades: The spiral blades are fixed on the screw shaft, and their shape and arrangement will affect the conveying effect of the material.

Pipeline: The pipeline is the outer shell of the conveyor, which is used to fix the screw shaft and spiral blades, while preventing the material from scattering or external interference. .

Feed port and discharge port: The feed port is used for the feeding of materials, and the discharge port is used for the discharge of materials. These ports are usually designed to be suitable for the smooth entry and exit of materials.

The ore screw conveyor uses the spiral blades to push or lift the ore or other granular materials along the pipeline through the rotation of the screw shaft to achieve material transportation. The working process is simple and efficient, including material feeding, the rotation of the screw shaft to push the material to move, and finally discharge the material at the discharge port.

Since our establishment, we have been committed to the research and development and manufacturing of conveying equipment. By introducing advanced production equipment and technology, we continuously improve our production capacity and product quality to meet the different needs of customers. We use high-quality materials and undergo strict quality control to ensure that the products are stable, reliable and durable. We provide a variety of customization options and customize screw conveyors of different specifications and models according to customer needs to meet the needs of different industries. We have a professional after-sales team to provide customers with timely technical support and maintenance services to ensure the stable operation of the product during use. Because the price bucket of each model is different, we recommend the most suitable product according to your needs, so if you have a conveying need, you can contact us and we will make a detailed price list for you.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!