Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Sand Screw Conveyor for sand loading is a kind of equipment specially designed for conveying and loading granular materials such as sand and gravel. It usually adopts a large-diameter spiral design with wear-resistant characteristics and a reinforced structure to meet the conveying needs of heavier materials such as sand and gravel.

According to different structures and application scenarios, sand screw conveyors can be divided into the following types:

Horizontal screw conveyor

Features: Horizontal conveying, simple structure, easy to install.

Application: Used for short-distance horizontal conveying of sand, commonly used in sand and gravel plants, construction sites, etc.

Inclined screw conveyor

Features: Sand can be conveyed to a high place, and the angle is adjustable.

Application: Used to convey sand from a low place to a high silo or equipment.

Vertical screw conveyor

Features: Vertical conveying, small footprint.

Application: Used to convey sand from the ground to a high silo or equipment.

U-shaped screw conveyor

Features: Flexible conveying path, horizontal, inclined and vertical conveying can be achieved.

Application: Suitable for occasions with limited space, can be customized according to on-site conditions.

Tube screw conveyor

Features: Closed conveying, prevent material leakage, suitable for dusty environments.

Application: Used to convey powdered materials and fine granular materials.

Shaftless screw conveyor

Features: No central shaft, strong conveying capacity, not easy to clog.

Application: Suitable for conveying materials with high viscosity or easy to be blocked.

Sand screw conveyors have a variety of specific applications in the industrial and construction fields, mainly including the following aspects:

Construction sites: used to transport sand from sand fields or warehouses to concrete mixing plants, mortar production lines and other locations at construction sites, facilitating the loading and use of sand in construction.

Concrete mixing plants: used to transport sand to concrete mixing plants, mix with cement, aggregates, etc., and produce concrete for use in construction projects.

Sand and gravel yards: used to transport granular materials such as sand and gravel from the yard to the production line or loading area, supporting the processing and utilization of sand and gravel.

Cement production line: used to transport raw materials such as sand to the cement production line, mix with other raw materials to make cement, and support the cement production process.

Glass manufacturing: used to transport raw materials such as quartz sand to the glass production line, supporting the loading and use of raw materials in the glass manufacturing process.

Grit sorting field: used to separate sand from mixed gravel, and realize the sorting and loading of sand of different particle sizes.

Ports and ships: used to load sand to ships at ports, facilitating sea transportation or dock operations, and meeting the needs of ship loading and unloading.

Sand screw conveyors have many specific advantages when conveying sand and other granular materials, including:

High conveying efficiency: It can convey sand continuously and evenly, improving production efficiency.

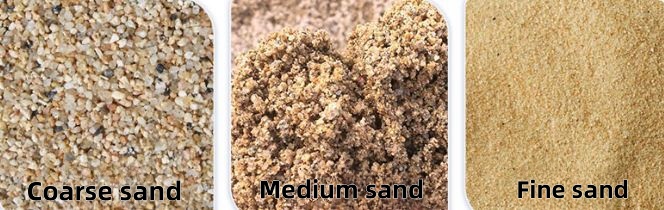

Strong adaptability: It is suitable for sand of different shapes, densities and particle sizes, and has strong adaptability.

Space saving: The compact design enables it to be conveyed in a limited space, saving space.

Reliable and stable: The structure is simple, the operation is stable and reliable, and the failure and maintenance costs are reduced.

Environmental protection: The noise and vibration generated during operation are small, and the impact on the environment is small.

Flexibility: The conveying speed and angle can be adjusted as needed to meet different process requirements.

Here are some suggestions when choosing a sand screw conveyor:

Consider the conveying distance and height: Determine the conveying distance and height according to actual needs, and select the appropriate model and specifications.

Understand the conveying volume requirements: Determine the handling capacity of the conveyor according to the amount of sand that needs to be conveyed per hour to ensure that production needs are met.

Consider the conveying angle: According to the actual process requirements and site conditions, select a suitable conveying angle, including horizontal, inclined or vertical conveying.

Choose the right material: Select the right conveyor material according to the properties of the conveyed sand (such as humidity, particle size, etc.) to ensure wear resistance and corrosion resistance.

Consider environmental factors: Consider factors such as temperature and humidity in the working environment, and select a conveyor with high temperature resistance, dust resistance and other characteristics.

Understand the production process requirements: According to the characteristics of the production process, select a screw conveyor with corresponding functions, such as cooling, heating or mixing functions.

In short, the sand screw conveyor for sand loading is an efficient and reliable material conveying equipment, which has been widely used in the construction, building materials and other industries. Through reasonable selection and use, it can greatly improve production efficiency and reduce labor intensity.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!