Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

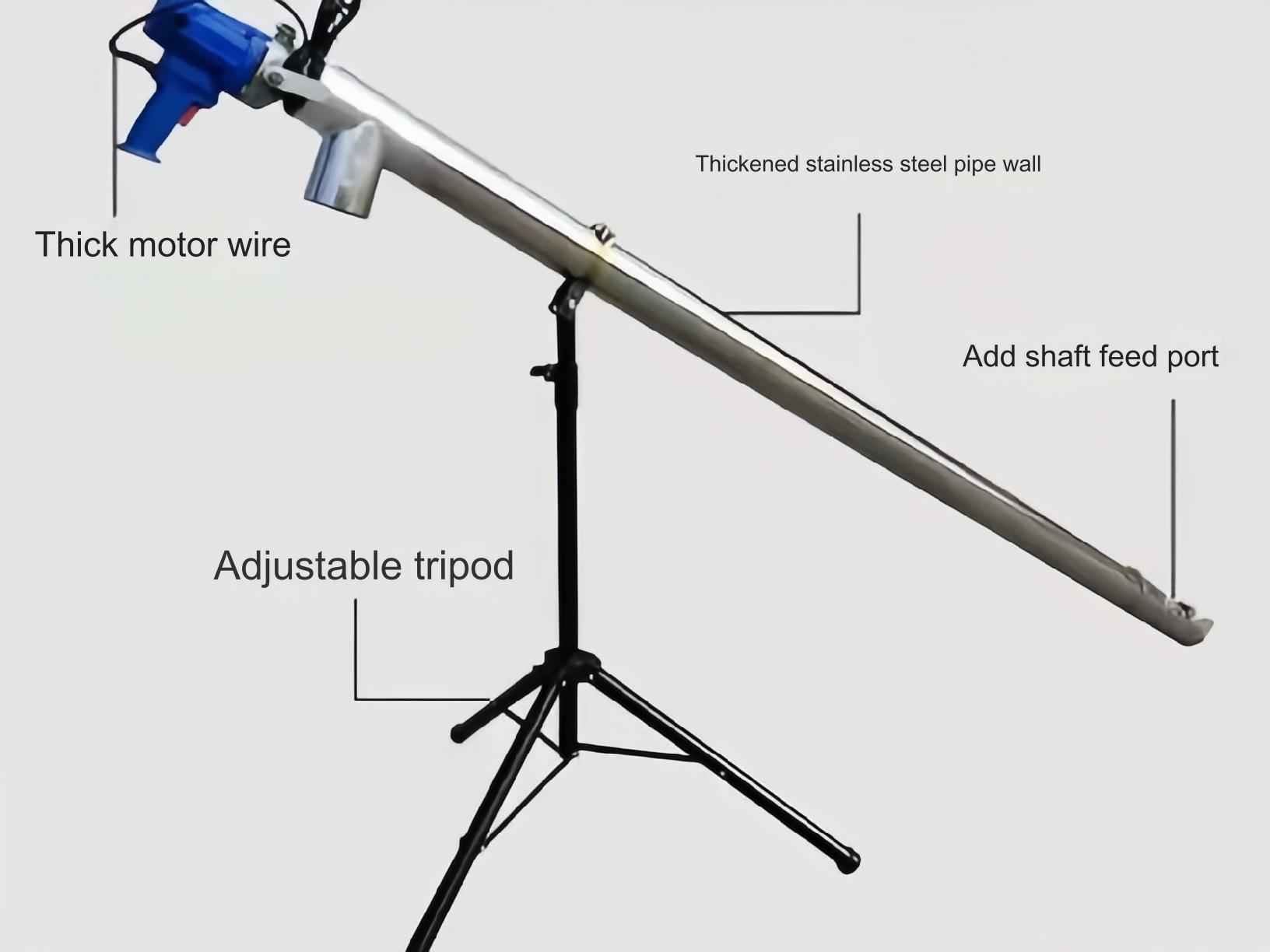

Stainless steel grain suction machine for urea is a mechanical device specially used for conveying urea granules. It uses the vacuum negative pressure principle to suck urea granules from the silo or the ground through the pipeline and convey them to the designated silo or equipment.

The stainless steel grain sucker for urea is a device used to convey urea granules or powder. Its working principle usually includes the following steps:

Suction stage: At the beginning of work, the stainless steel grain sucker forms a negative pressure environment through devices such as suction fans or vacuum pumps. When the negative pressure is formed, the urea granules or powder are sucked into the suction port of the grain sucker.

Conveying stage: The sucked urea granules or powder are conveyed into the equipment under the action of negative pressure, and move to the target position along the conveying path of the equipment through conveying pipes or screw conveyors.

Discharge stage: When the urea granules or powder reach the target position, the working state of the grain sucker is adjusted by the control device, and the urea granules or powder are discharged to the designated position to complete the conveying task.

Stainless steel grain suckers for urea are widely used in the production and transportation of fertilizers, mainly including the following aspects:

Urea production line: In the urea production process, stainless steel grain suckers can be used to transport urea granules or powders, and transport raw materials from one process to another to ensure the continuity and efficiency of the production line.

Urea storage and packaging: Stainless steel grain suckers can be used to transport urea products from the production line to the storage area or packaging area, which is convenient for storage and packaging operations.

Urea mixing and proportioning: In the urea mixing and proportioning process, stainless steel grain suckers can be used to transport urea products with different proportions to ensure proportion accuracy and production efficiency.

Urea transportation: Stainless steel grain suckers can be used to transport urea products from the production site to the loading area or to the customer, realizing the fast and safe transportation of urea products.

Urea packaging line: On the urea packaging line, stainless steel grain suckers can be used to transport urea products to the packaging machinery, realize automatic packaging operations, and improve packaging efficiency.

Urea processing: In the urea processing, stainless steel grain suction machine can be used to transport urea granules or powder to different processing equipment to assist in completing the processing process.

Stainless steel grain suckers for urea have many advantages, including but not limited to the following:

Corrosion resistance: Stainless steel has excellent corrosion resistance, can resist corrosion from chemicals such as urea, and extend the service life of the equipment.

Sanitary and safe: Stainless steel is easy to clean, non-toxic and odorless, and meets food-grade hygiene standards, ensuring that the transported urea is clean and hygienic to avoid pollution.

Wear resistance: Stainless steel has high hardness and wear resistance, can resist the wear of urea particles, and reduce equipment loss.

Easy to clean: The surface of stainless steel is smooth and flat, and it is not easy to adhere to dirt, which is easy to clean and maintain, keeping the equipment clean and hygienic.

High temperature resistance: Stainless steel has good high temperature resistance and is suitable for working environments that require the transportation of high-temperature urea.

High reliability: Stainless steel grain suckers have stable performance and reliable operation, and can continuously and efficiently transport urea to improve production efficiency.

When choosing a stainless steel conveyor for urea, you can consider the following suggestions:

Material quality: Choose a stainless steel conveyor to ensure its corrosion resistance and wear resistance to cope with the characteristics of chemical substances such as urea.

Capacity: According to production needs and usage, choose a conveyor with appropriate capacity to ensure that it can meet the needs of the production line.

Power: Consider the power of the conveyor to ensure that it can effectively absorb and transport materials such as urea to improve production efficiency.

Ease of operation: Choose a conveyor that is simple to operate and easy to maintain to reduce the difficulty of operation and maintenance costs.

Safety: Ensure that the conveyor has safety protection devices to avoid accidents and ensure the safety of operators.

In short, as an efficient, safe and reliable material conveying equipment, the stainless steel urea suction machine plays an important role in fertilizer production and agricultural production. The advantage of its stainless steel material enables it to better adapt to the corrosiveness of urea and ensure the smooth progress of the conveying process.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!