Whatsapp:+86 18339211009 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

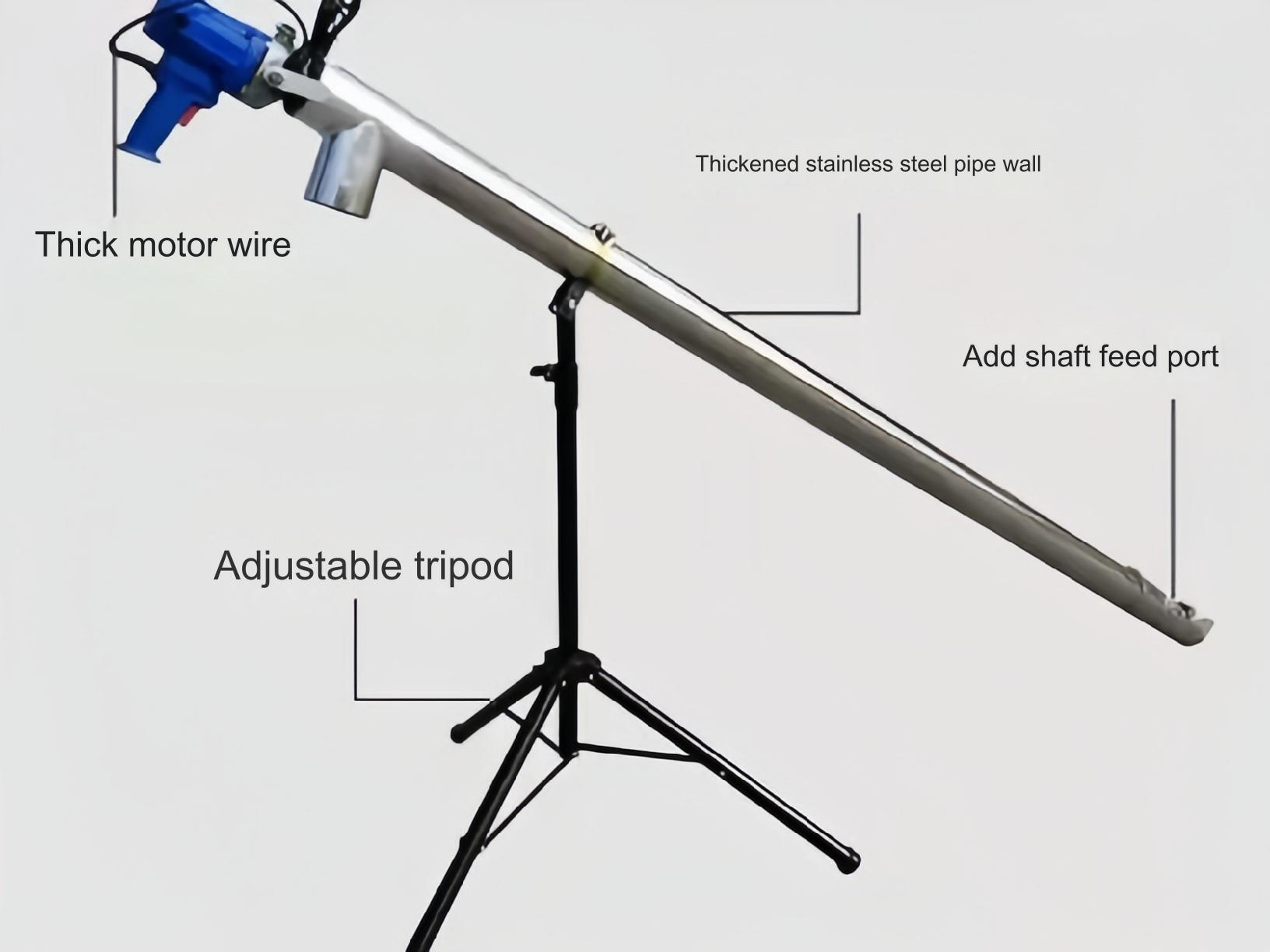

Stainless steel grain suction machine for cement is a kind of equipment used in cement mixing station or concrete mixing station and other projects. It is a mechanical device used to transport cement or other bulk materials. It is usually made of stainless steel, which has the characteristics of corrosion resistance and wear resistance, and is suitable for long-term use in construction sites such as mixing stations.

The cement stainless steel suction machine is a device used for conveying granular materials. Its working principle mainly includes the following steps:

Material suction: The cement stainless steel suction machine uses the negative pressure principle to generate negative pressure using a fan or vacuum pump to suck the granular materials into the pipeline system.

Conveying: The sucked granular materials are transported to the target location in the pipeline system through the action of airflow. The pipeline system is usually designed with structures such as elbows and branch pipes to ensure that the granular materials can be smoothly transported to the designated location.

Separation: During the conveying process, a mixture of granular materials and airflow may be produced. The cement stainless steel suction machine usually designs a separation device, such as a filter or a dust collector, to separate the granular materials and the airflow to ensure that only the granular materials reach the target location.

Unloading: When the granular materials are transported to the target location, the cement stainless steel suction machine will unload the granular materials into the designated equipment or container through the corresponding unloading device to complete the conveying task.

Cement stainless steel suction machine is widely used in cement mixing station, concrete mixing station and other granular material conveying scenarios. The following are some application fields of cement stainless steel suction machine:

Cement mixing station: Cement stainless steel suction machine is used to convey raw materials such as cement, sand, stone, etc. to the mixer for mixing to ensure the continuity and stability of the production process.

Concrete mixing station: In the concrete mixing station, cement stainless steel suction machine is used to convey raw materials such as cement, sand, aggregate, etc. to the concrete mixer for mixing to ensure the quality and production efficiency of concrete.

Construction site: Cement stainless steel suction machine can also be used for granular material conveying on construction sites, such as conveying sand, stone, etc. to the construction site to meet construction needs.

Chemical industry: In the chemical industry, cement stainless steel suction machine can be used to convey chemical raw materials or products, such as granular chemical raw materials, powder, etc.

Mining field: In the mining field, cement stainless steel suction machine can be used to convey granular materials such as ore and coal to meet the material conveying needs of mine production.

Cement stainless steel suction machine has many advantages in projects such as cement mixing plants and concrete mixing plants, including but not limited to the following:

Corrosion resistance: Stainless steel has excellent corrosion resistance, can resist the erosion of cement and other chemicals, and extend the service life of the equipment.

Wear resistance: Stainless steel suction machine has high wear resistance, can maintain good conveying performance during long-term use, and reduce the frequency of equipment maintenance and replacement.

Efficient conveying: Cement stainless steel suction machine can realize automated material conveying, improve production efficiency, reduce labor costs, and ensure the continuity and stability of the production process.

Stability: Cement stainless steel suction machine has stable operating performance, can continuously convey materials for a long time, and ensure the stability and continuity of the production process.

Choosing a suitable stainless steel cement pelletizer requires considering multiple factors, including project requirements, production scale, material characteristics, and equipment performance. Here are some suggestions:

Production scale: First, consider the production scale of the project and determine the amount of cement or other granular materials that need to be transported every day. Select the appropriate pelletizer model and throughput according to production requirements.

Material characteristics: Consider the characteristics of the conveyed material, such as particle size, density, viscosity, etc. Different material characteristics may require different types of pelletizers to ensure effective transportation and operation.

Working environment: Consider the working environment of the cement mixing plant or concrete mixing plant, including factors such as temperature, humidity, and dust. Choose corrosion-resistant and wear-resistant stainless steel materials to adapt to harsh working environments.

Energy consumption and efficiency: Consider the energy consumption and operating efficiency of the equipment, and choose a pelletizer with high energy efficiency and stable operation to reduce production costs and improve production efficiency.

In general, cement stainless steel particle suction machine plays an important role in projects such as cement mixing stations and concrete mixing stations. Through automated material transportation, it improves production efficiency and ensures the smooth progress of project construction.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!