Whatsapp:+86 15236742901 Address: 1000 meters west of the gate of Yanjin County Forest Park, Xinxiang City, Henan Province.

Tubular Screw Conveyor is a traditional material conveying equipment, which is widely used in various industries because of its long conveying distance and continuous feeding. When selecting a tubular screw conveyor, some key factors need to be considered, including the characteristics of the conveyed material, flow rate, conveying distance, discharge height, slope, working environment, transportation method, etc. This article will introduce in detail how to choose a tubular screw conveyor and the matters needing attention.

1. Material characteristics

The selection of the tubular screw conveyor first needs to consider the characteristics of the conveyed material. The type of material, density, viscosity, humidity, particle size, temperature, pressure and other factors will affect the choice of conveyor. For powdery materials, hollow spiral tubes are generally used, and solid spiral tubes are used for granular materials. If the material is wet, a specially coated spiral tube must be used. Therefore, before selecting a tubular screw conveyor, it is necessary to conduct detailed physical property testing and analysis of the transported materials.

2. Traffic

Flow refers to the quantity of material conveyed per unit time. When selecting a tubular screw conveyor, it is necessary to consider whether the flow rate of the material can meet the production demand. The flow rate needs to be estimated and determined according to the specific conditions of the material, combined with the process requirements, working environment and other factors, so as to ensure the normal operation of the conveyor and the improvement of production efficiency.

3. Conveying distance

The conveying distance refers to the distance from the starting point of the conveyor to the end point of the material, including the distance in the horizontal and vertical directions. The length of the conveying distance is also one of the factors that need to be considered in the selection of the tubular screw conveyor, because it determines the parameters of the motor power of the conveyor, the diameter of the conveying pipe, and the structure of the screw drive.

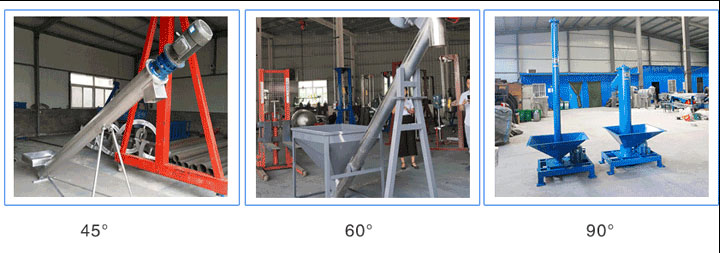

4. Discharge height and slope

The discharge height refers to the vertical distance of the material from the conveyor outlet to the ground. If the unloading height is too high, the motor power and stability of the conveyor need to be increased; if the unloading height is too low, the flow and conveying efficiency of materials will be affected. Conveyor slope affects the flow and speed of the conveyor.

5. Working environment

The characteristics of the working environment need to be considered when selecting a tubular screw conveyor. Such as working conditions, ambient humidity, ambient temperature, operation mode, power supply voltage, etc. The poor working environment of the conveyor will seriously affect the performance and life of the conveyor.

6. Shipping method

The selection of tubular screw conveyor needs to consider the mode of transportation. The size and weight of the conveyor directly affects the handling and shipping methods. If the conveyor is large or needs to be transported remotely, it needs to be disassembled or transported by loading.

1. Fully consider the characteristics of the material and the conveying distance, and determine the model and specification of the conveyor.

2. Calculate and confirm the motor power and conveying speed of the conveyor according to the flow rate of conveyed materials, conveying pipe diameter and other parameters.

3. Before selecting the tubular screw conveyor, carry out detailed physical property testing and analysis on the transported materials to understand the technical requirements of the characteristics of the materials.

4. The special requirements of the working environment should be considered when selecting the model, such as the temperature, humidity, pressure, explosion-proof, etc. of the conveyed materials.

5. Use high-quality conveyor manufacturers, and ensure that the conveyor is equipped with sufficient motor controllers, drives and other auxiliary equipment to ensure the long-term stable operation of the conveyor.

In short, there are many factors to consider when selecting a suitable tubular screw conveyor. Reasonable selection from the characteristics of materials, flow rate, conveying distance, discharge height, slope, working environment, transportation mode and other aspects can meet the production needs and ensure the normal operation and life of the conveyor.

NOTE: You can also send a message to us by this email sale@xxdahan.com, we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!